Welding device and method

A welding device and a welding method technology are applied in the fields of welding devices for copper pipes and copper pipes, aluminum pipes and aluminum pipes, and copper pipes and aluminum pipes, to achieve the effects of less leakage, convenient operation, and easy control of welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

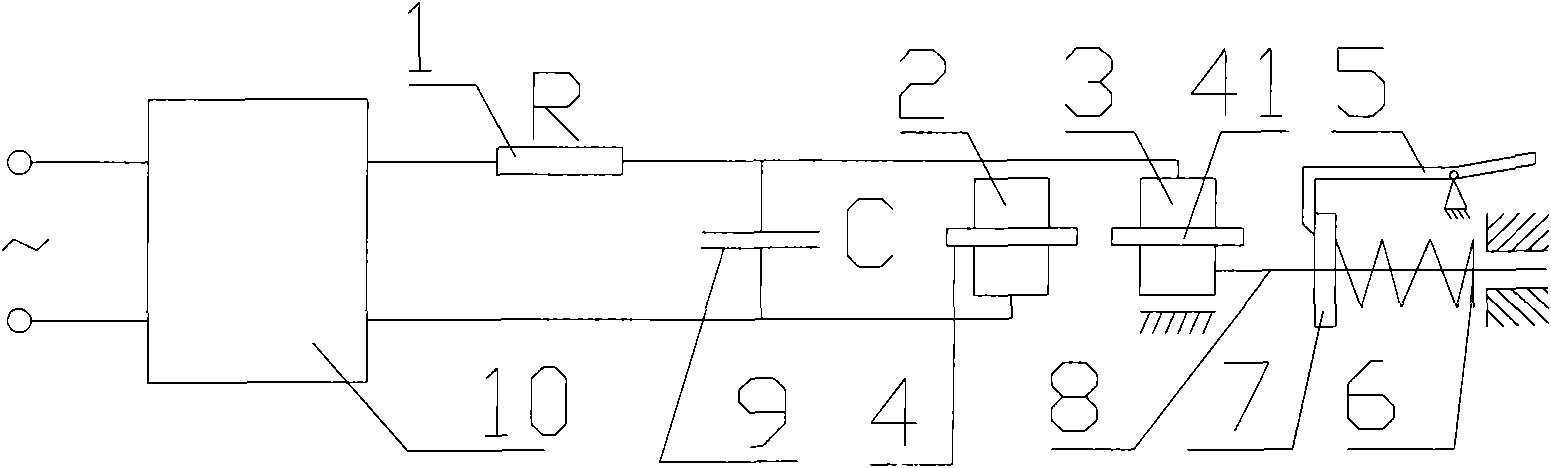

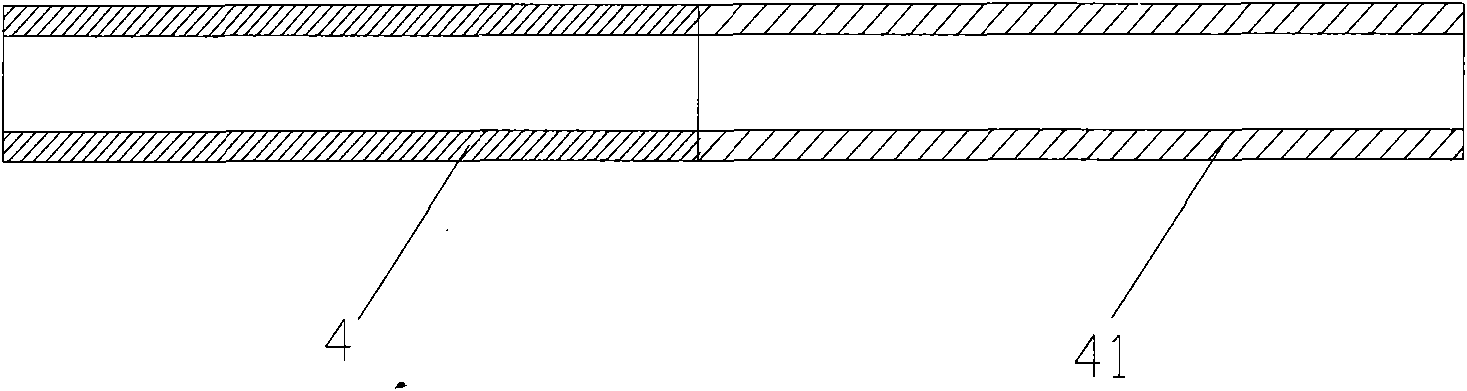

[0026] Please refer to the attached figure 1 , a schematic diagram of a welding device of the present invention, a welding device comprising a current-limiting resistor 1, a fixed fixture 2, a moving fixture 3, a capacitor 9, and a power supply and a control system 10, wherein the power supply and the control system 10 are connected to the current-limiting resistor 1 and the capacitor 9 form a loop, and the capacitor 9 is connected to the fixed fixture 2 and the moving fixture 3 to form a loop; the first weldment 4 is clamped in the fixed fixture 2, the second weldment 41 is clamped in the moving fixture 3, and the second weldment 41 The position adjustment device A is connected, the position adjustment device A is connected with the spring 6 and the locking device 5 is installed in the position adjustment device A; the pre-compression of the spring 6 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

| Overhang | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com