Braze-welding cubic boron nitride high-temperature copper-based active solder and preparing method thereof

A cubic boron nitride and active solder technology, applied in welding equipment, welding/cutting medium/material, welding medium, etc., can solve the problems of high temperature performance thermal stability mismatch, low working temperature, unsatisfactory, etc. Low cost, high working temperature and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

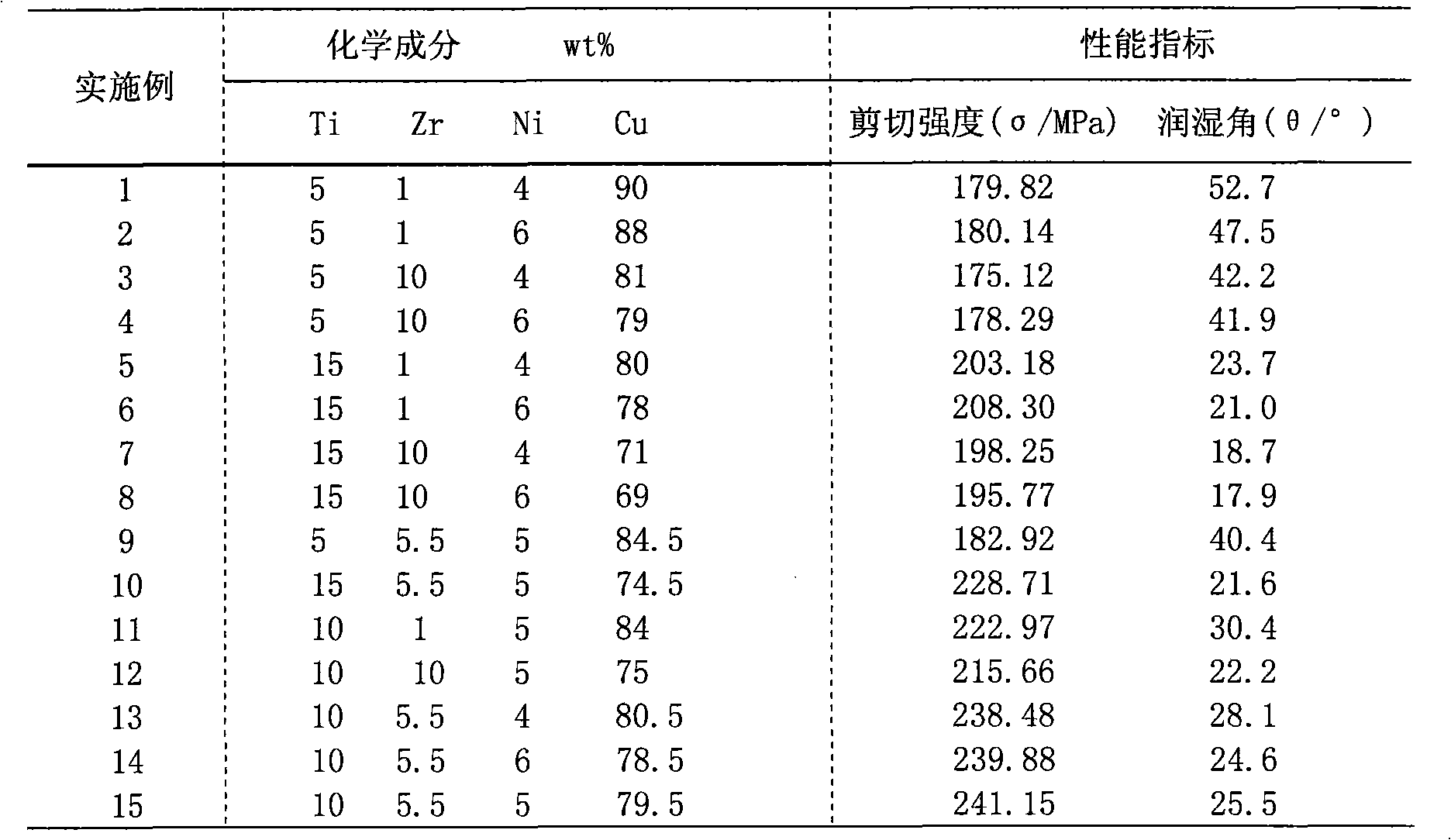

Examples

Embodiment Construction

[0012] The method of the present invention will be further described in detail through the examples given below.

[0013] In the invention, Cu, Ni, Zr, and Ti metals with a particle size of 180-200 μm and a purity of 99.99% are combined according to an optimized test ratio, and are uniformly mixed and smelted in a high vacuum brazing furnace. During vacuum melting, the degree of vacuum, melting temperature and holding time all have an important influence on the connection quality of Cu-Ni-Zr-Ti brazing c-BN products and tools. The active elements are easily oxidized and cannot react with c-BN after oxidation. In order to prevent the oxidation of active elements, during the smelting process of high temperature copper-based active solder, the vacuum value should be less than 2.9×10 -3 Pa. The smelting temperature should be controlled at 1050-1150℃, and the holding time should be 10 minutes to ensure that the active elements have sufficient thermodynamic activity. In order to make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com