Mold for oil seal

A technology for oil seals and molds, which is applied in the field of molds for oil seals. It can solve the problems of difficult to guarantee the structure of oil seals, the inability to solve the structural errors of oil seal lips, and the same large cutting cavity. The effect of dropping the risk of refurbishment errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following examples are used to illustrate the present invention, but are not intended to limit the protection scope of the present invention.

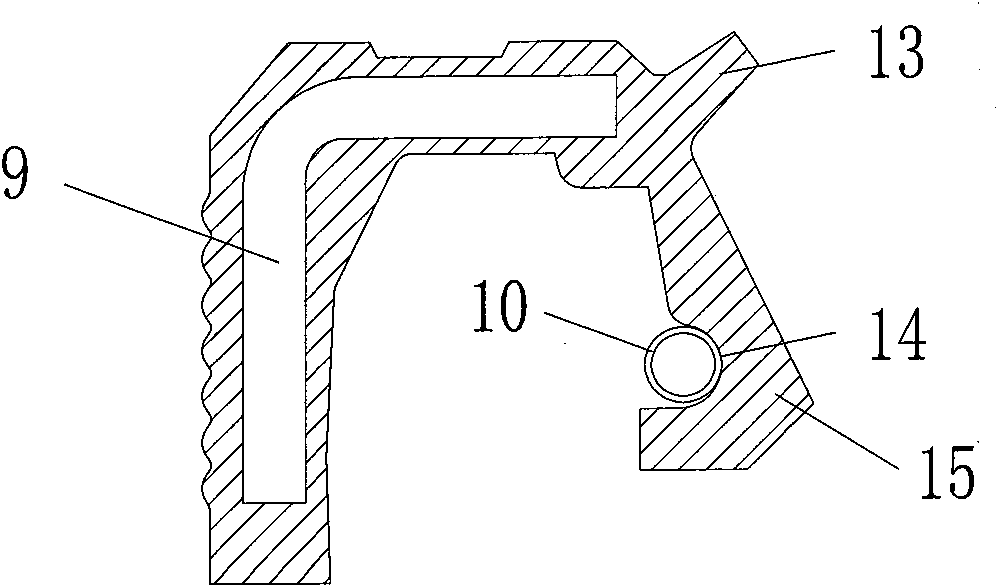

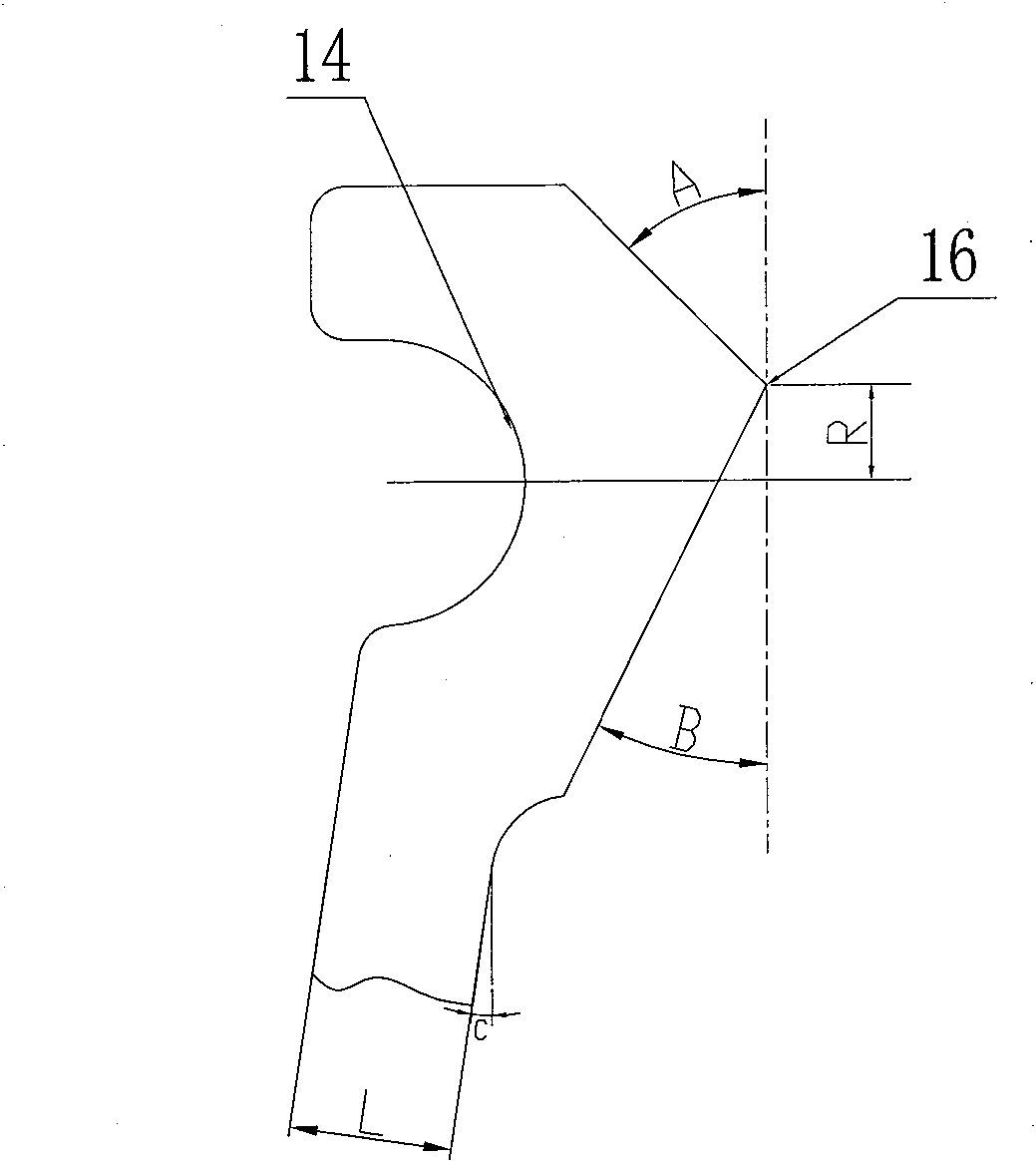

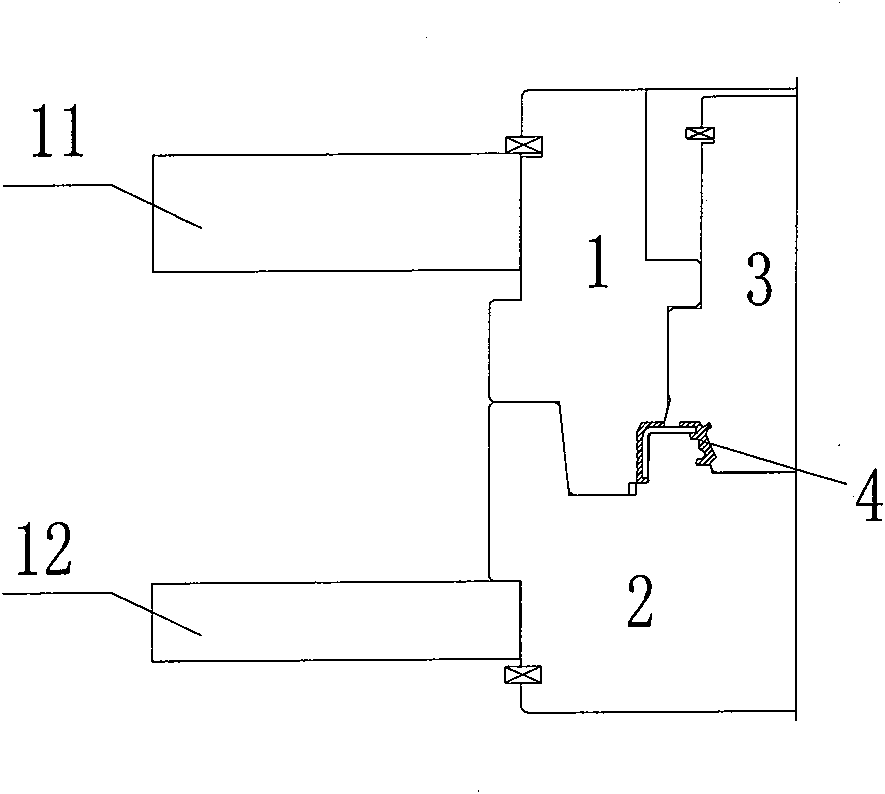

[0049] Figure 5 It is a structural representation of the mold for the oil seal of the present invention; as Figure 5 As shown, the mold for oil seal of the present invention includes an outer diameter upper mold 1, an oil seal lip mold core and a spring groove lower mold, and the oil seal lip mold core is composed of a half auxiliary lip mold core 8 and a main lip and a half auxiliary lip mold core 5, the spring groove lower die is composed of a spring groove combined lower die 7 and a spring groove tightly matched insert core 6.

[0050] Among them, the main lip and half auxiliary lip mold core 5 and the spring groove combination lower mold 7 and the spring groove tightly fitted insert core 6 follow the movement, and are located on the positioning plate 12 of the lower mold, and the half auxiliary lip mold core 8 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com