Longmen broad width three-dimensional solid body laser inner carving apparatus with high speed

A three-dimensional, laser engraving technology, used in decorative arts, processing models, etc., can solve the problems of inability to meet the requirements of repeated positioning accuracy, the influence of the accuracy of optical path transmission, and the span of the gantry cannot be too large, so as to ensure the accuracy of optical path transmission. , The effect of reducing machining accuracy requirements, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

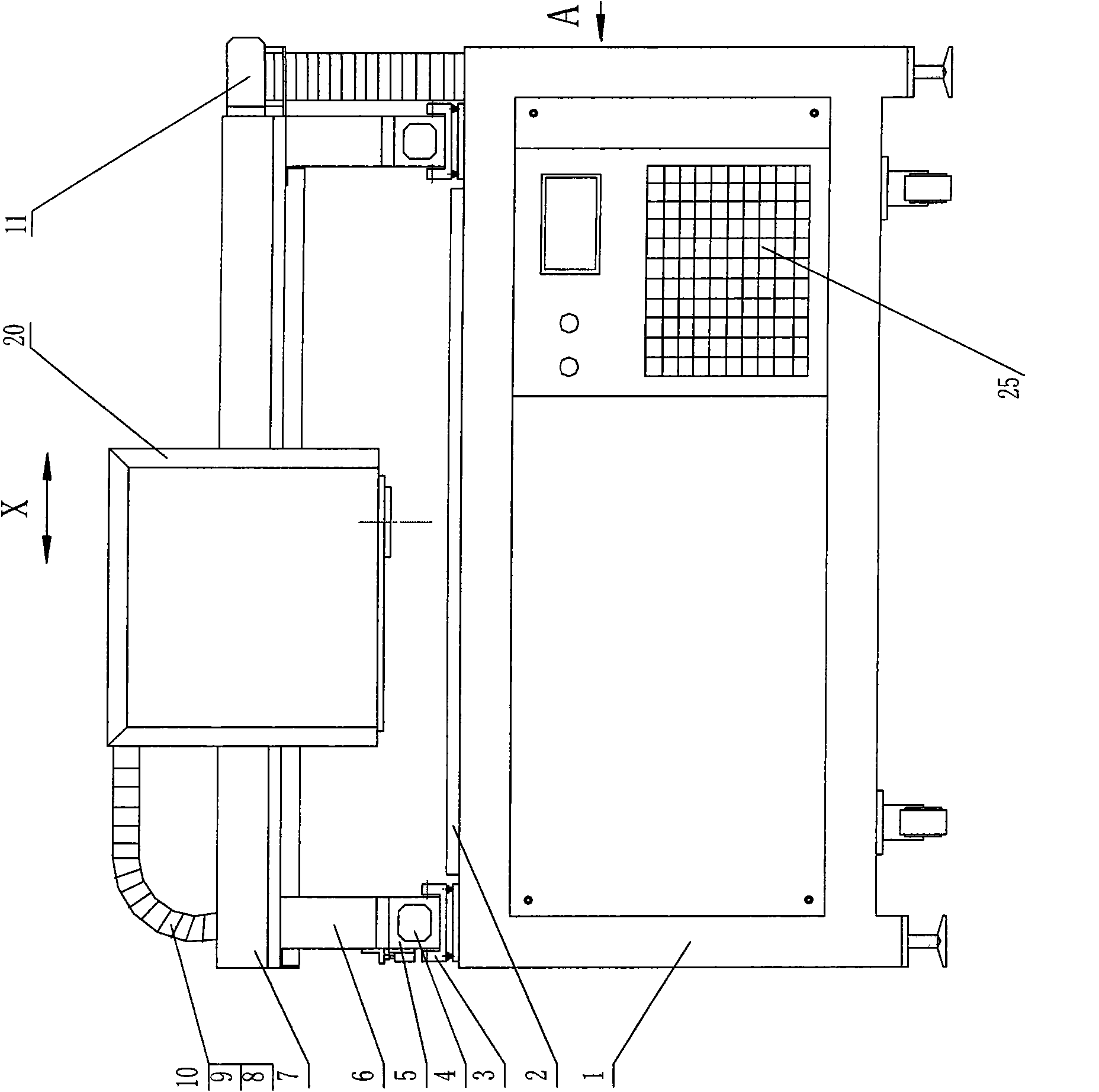

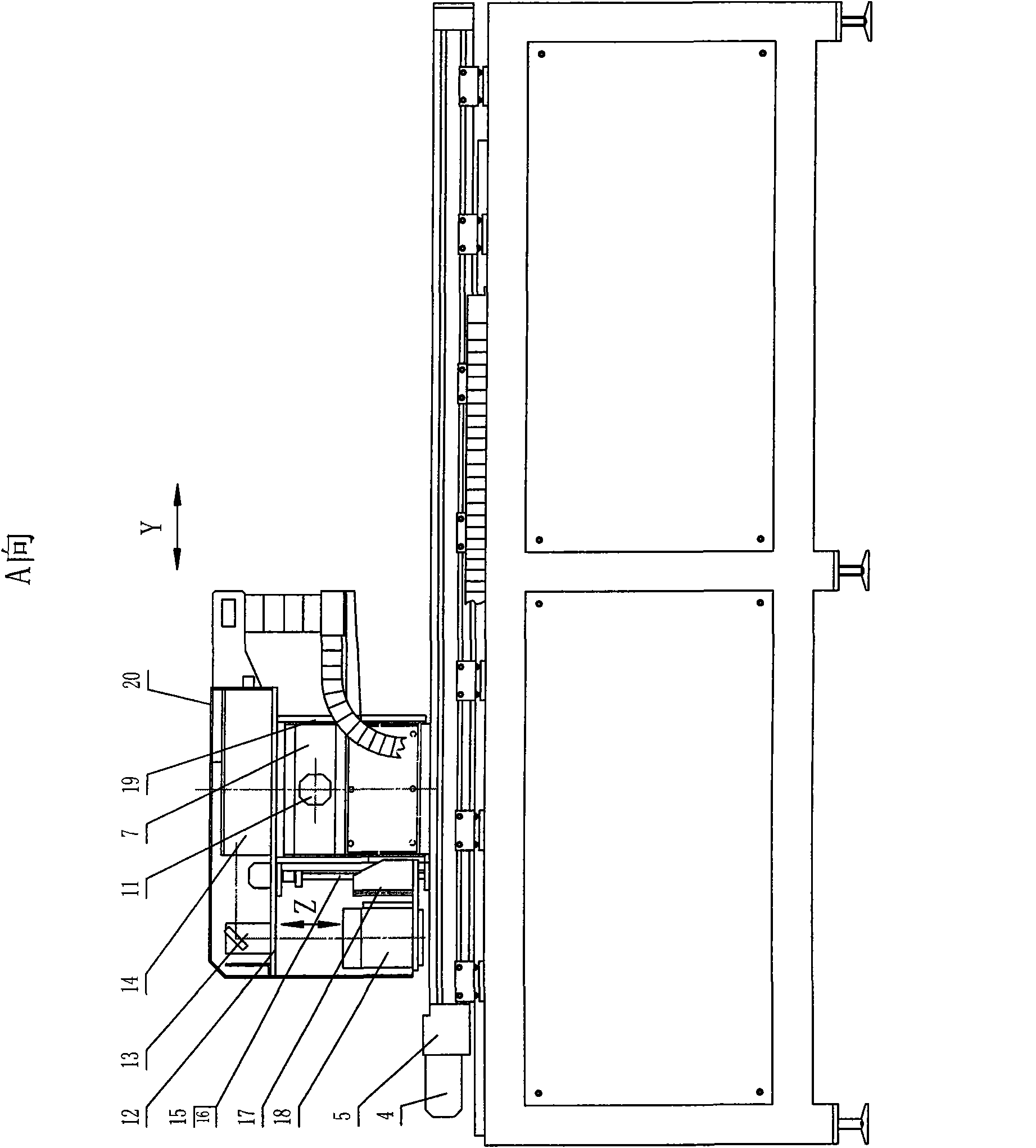

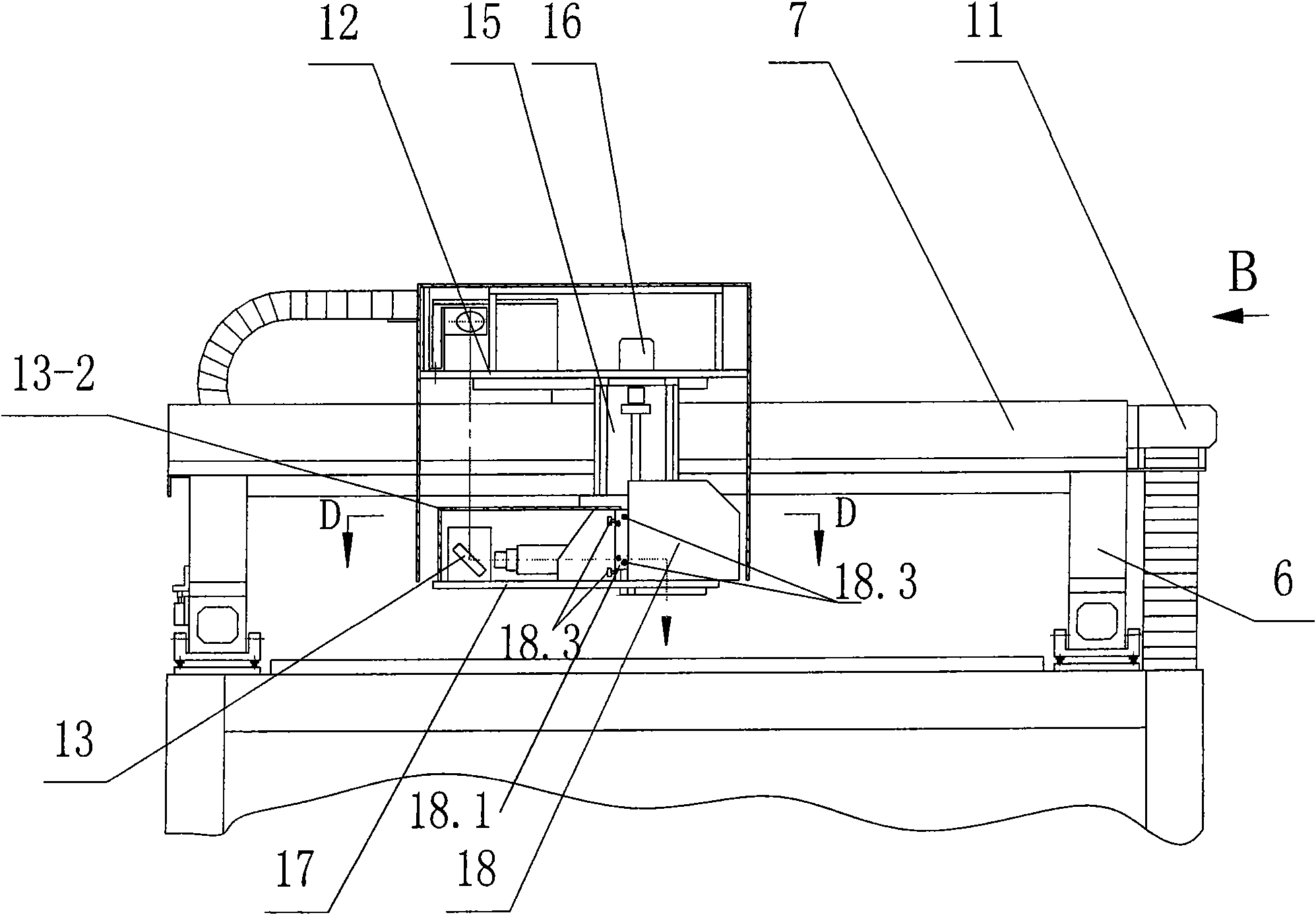

[0027] like figure 1 As shown, the gantry wide-width high-speed three-dimensional laser engraving machine includes a laser cooling device 25 installed in the body support 1. The body support 1 is provided with a work surface to install a T-shaped work surface 2. Two sides of the body support on the work surface are provided. Y-axis motion support track and Y-axis drive transmission device 5, Y-axis motion support track is located on the Y-axis motion support track horizontal fine-tuning device 3 ( figure 2 Middle); the two Y-axis motion support rails and the Y-axis drive transmission device 5 are connected with a large-span gantry support 6, and the two large-span gantry supports 6 are connected with an X-axis motion support rail that can move along the Y-axis motion support rail and X-axis drive transmission device 7, X-axis motion support track and X-axis drive transmission device 7 are connected to motion platform 12, and motion platform 12 is connected to Z-axis motion tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com