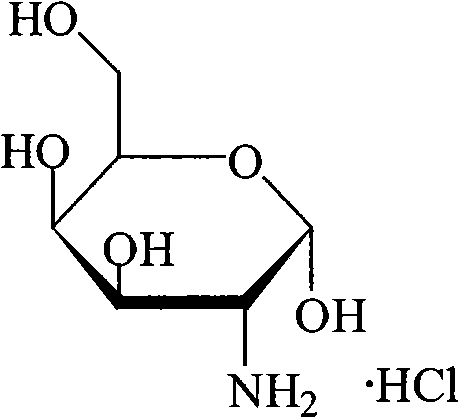

Production technology separating glucosamine hydrochloride from citric acid sludge

A technology of glucosamine hydrochloride and citric acid residue, applied in amino sugar, sugar derivatives, sugar derivatives and other directions, can solve problems such as short hydrolysis time, achieve the effects of good repeatability, high yield and avoid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Dry 1000 g of citric acid residue and hydrolyze with 2500 ml of 31% hydrochloric acid at a temperature of 95° C. for 3 hours. Cool to below 70°C, filter, wash the filter residue with 500ml of pure water, combine the filtrate, and then transfer it to a D101 macroporous resin column with 200ml of resin in the adsorption column, control the flow rate at 200ml / hour during adsorption, and then wash the resin with 600ml of pure water Column, combined effluent and water washes. The decolorizing liquid is concentrated in vacuum, the vacuum degree is controlled at -0.80--0.99Mpa, the temperature is controlled below 80°C, concentrated until a large number of crystals appear, and cooled and settled for 24 hours. Filtrate the crude crystalline product, dissolve the crude crystalline product with 200ml of pure water, then pass through a 0.45μm microporous membrane, concentrate the microfiltrate in vacuum, control the vacuum at -0.80--0.99Mpa, control the temperature below 80°C, and ...

Embodiment 2

[0055] 1000 g of dried citric acid residue was hydrolyzed with 3000 ml of 25% hydrochloric acid at a temperature of 100° C. for 3.5 hours. Cool to below 70°C, filter, wash the filter residue with 500ml of pure water, combine the filtrate, and then transfer it to a D138 macroporous resin column. The adsorption column is filled with 200ml of resin, and the flow rate during adsorption is controlled at 200ml / hour, and then the resin is washed with 600ml of pure water Column, combined effluent and water washes. The decolorizing liquid is concentrated in vacuum, the vacuum degree is controlled at -0.80--0.99Mpa, the temperature is controlled below 80°C, concentrated until a large number of crystals appear, and cooled and settled for 24 hours. Filtrate the crude crystalline product, dissolve the crude crystalline product with 200ml of pure water, then pass through a 0.2μm microporous membrane, concentrate the microfiltrate in vacuum, control the vacuum at -0.80--0.99Mpa, control the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com