Dual-function knitted catalytic gauze used for nitric acid manufacture

A technology for knitting catalytic nets and catalytic nets, applied in nitric acid, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of large filling amount of precious metal platinum, low utilization rate and large platinum consumption and other problems, to achieve the effect of reducing production costs, reducing platinum consumption, and reducing platinum consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

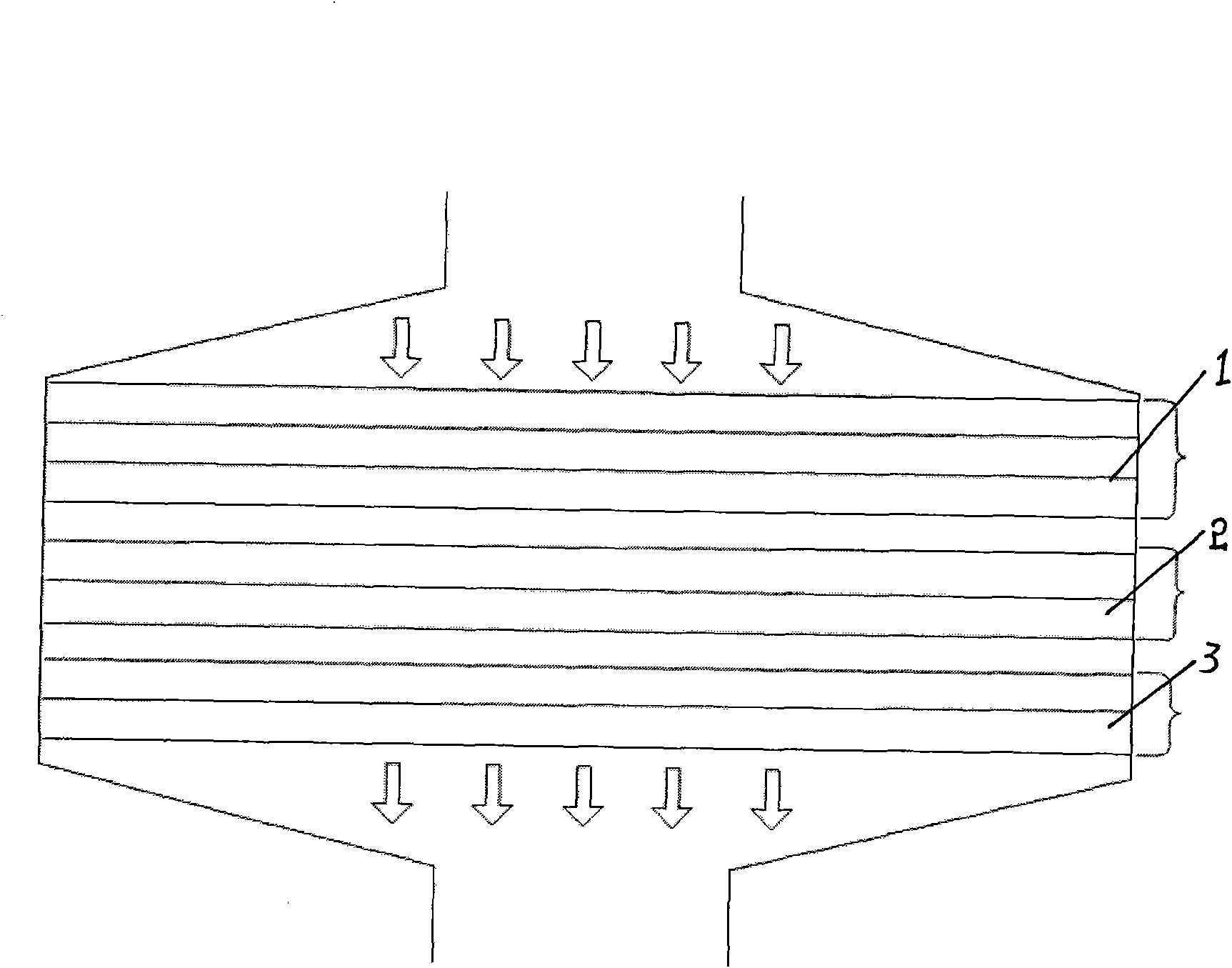

[0015] Double-function knitted catalytic net for nitric acid production, the knitted catalytic net includes the catalytic net in the main reaction zone, the catalytic net in the secondary reaction zone and the catalytic net in the supplementary reaction zone, which are divided according to the direction of the ammonia gas flow in the ammonia oxidation furnace. The catalytic net used in the reaction zone where the ammonia oxidation rate reaches 70% is called the main reaction zone catalytic net, and its composition weight percentage is 92% platinum, 4% rhodium, 4% palladium, the main reaction zone catalytic net is the same as the standard platinum The wire diameter ratio of the net is 1.20:1; the catalytic net used in the reaction zone where the ammonia oxidation rate reaches 25% is called the secondary reaction zone catalytic net, and its composition contains 50% platinum by weight, 5% rhodium, 45% palladium, and the addition is 0.1% nickel of the sum of platinum, rhodium and p...

Embodiment 2

[0018] Double-function knitted catalytic net for nitric acid production, the knitted catalytic net includes the catalytic net in the main reaction zone, the catalytic net in the secondary reaction zone and the catalytic net in the supplementary reaction zone, which are divided according to the direction of the ammonia gas flow in the ammonia oxidation furnace. The catalytic net used in the reaction area where the ammonia oxidation rate reaches 80% is called the main reaction area catalytic net, and its composition is 91% platinum, 8% rhodium, and 1% palladium. The main reaction area catalytic net is the same as the standard The diameter ratio of the platinum net is 1.05:1; the catalytic net used in the reaction zone where the ammonia oxidation rate reaches 10% is called the catalytic net in the secondary reaction zone, and its composition contains 73% platinum by weight, 5% rhodium, 22 % palladium, and the addition of 0.2% cerium that is the sum of platinum, rhodium and palladi...

Embodiment 3

[0021] Double-function knitted catalytic net for nitric acid production, the knitted catalytic net includes the catalytic net in the main reaction zone, the catalytic net in the secondary reaction zone and the catalytic net in the supplementary reaction zone, which are divided according to the direction of the ammonia gas flow in the ammonia oxidation furnace. The catalytic net used in the reaction zone where the ammonia oxidation rate reaches 75% is called the main reaction zone catalytic net, and its composition is 91% by weight of platinum, 4% rhodium, and 5% palladium. The main reaction zone catalytic net is the same as the standard The diameter ratio of the platinum net is 1.18:1; the catalytic net used in the reaction zone where the ammonia oxidation rate reaches 18% is called the secondary reaction zone catalytic net, and its composition contains 73% platinum by weight, 7% rhodium, 20 % palladium, and the addition of 3% cobalt that is the sum of platinum, rhodium and pal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com