Method for preparing zinc aluminate nano-material

A technology of nanomaterials and zinc aluminate, which is applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of difficult recycling of residues, cumbersome preparation process, long preparation cycle, etc., and achieve short preparation cycle and process Simple process and easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution will be further described in detail below in conjunction with the accompanying drawings.

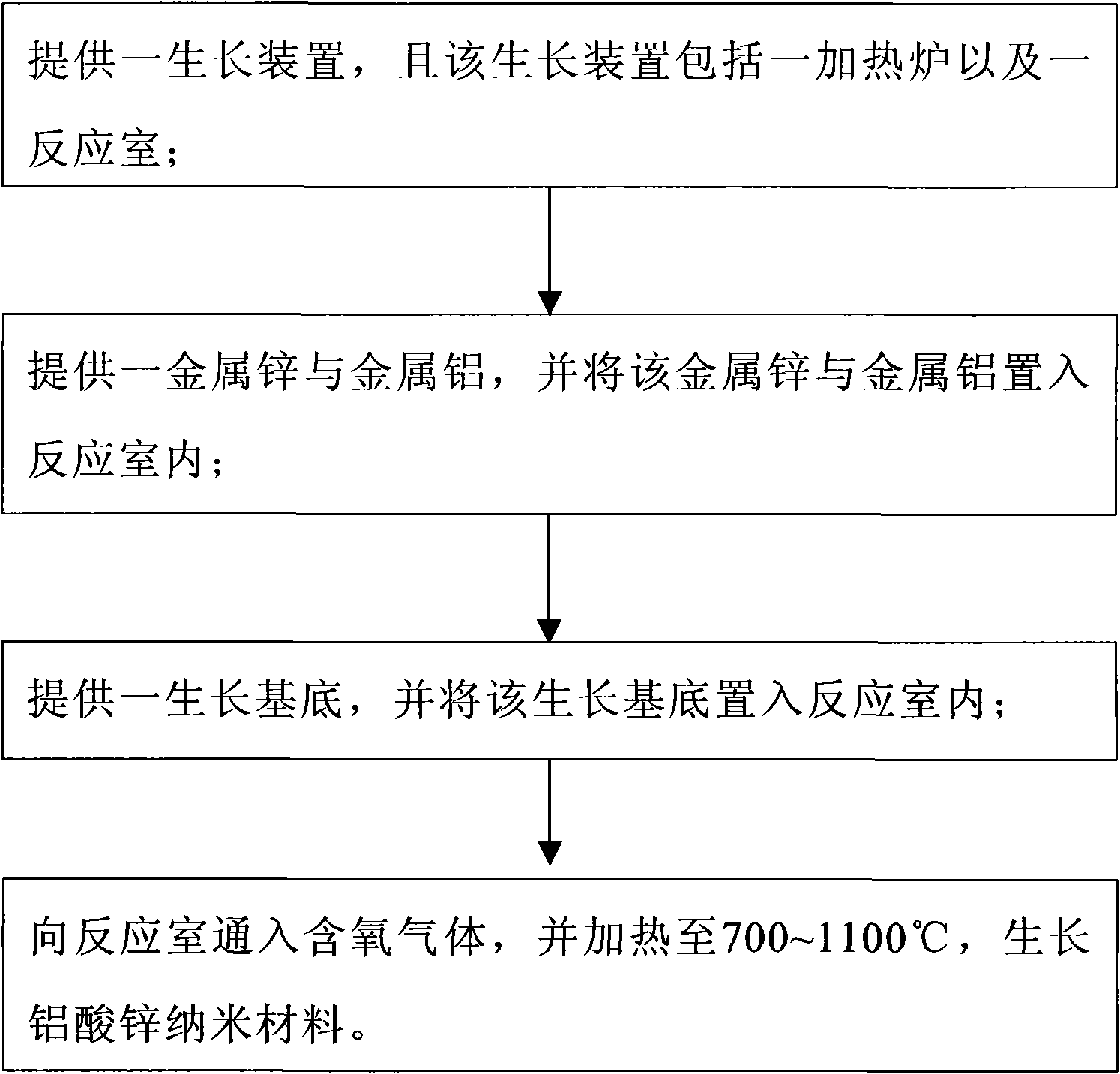

[0014] see figure 1 and figure 2 The embodiment of this technical solution provides a method for preparing zinc aluminate nanomaterials, which specifically includes the following steps:

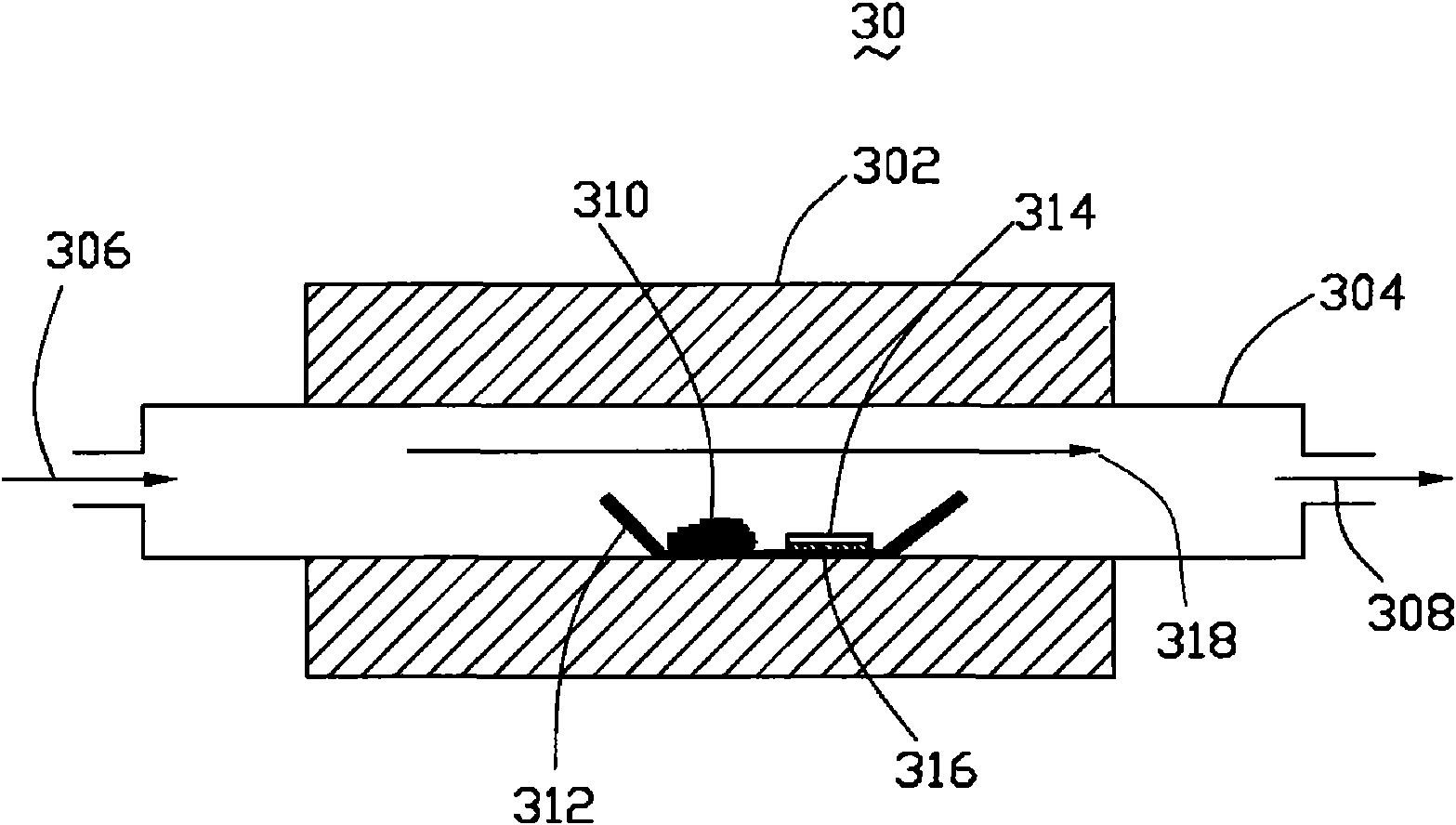

[0015] In step 1, a growth device 30 is provided, and the growth device 30 includes a heating furnace 302 and a reaction chamber 304 .

[0016] In this embodiment, the reaction chamber 304 is preferably a quartz tube with a gas inlet 306 and a gas outlet 308 at both ends thereof. The quartz tube is movable in the heating furnace 302, and its length is longer than the heating furnace 302, so that when the quartz tube is pushed and pulled in the experiment, a part of the quartz tube can always be placed in the heating furnace 302.

[0017] The reaction chamber 304 also includes a carrying device 312 which is a container with a high melting point. In this embodiment, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com