Microwave medium ceramic material with ultrahigh Q-value middle dielectric constant

A technology of microwave dielectric ceramics and electrical constants, applied in ceramics, inorganic insulators, etc., can solve the problems of high dielectric constant and low quality factor, and achieve the effects of convenient operation, simple manufacturing process, and large industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

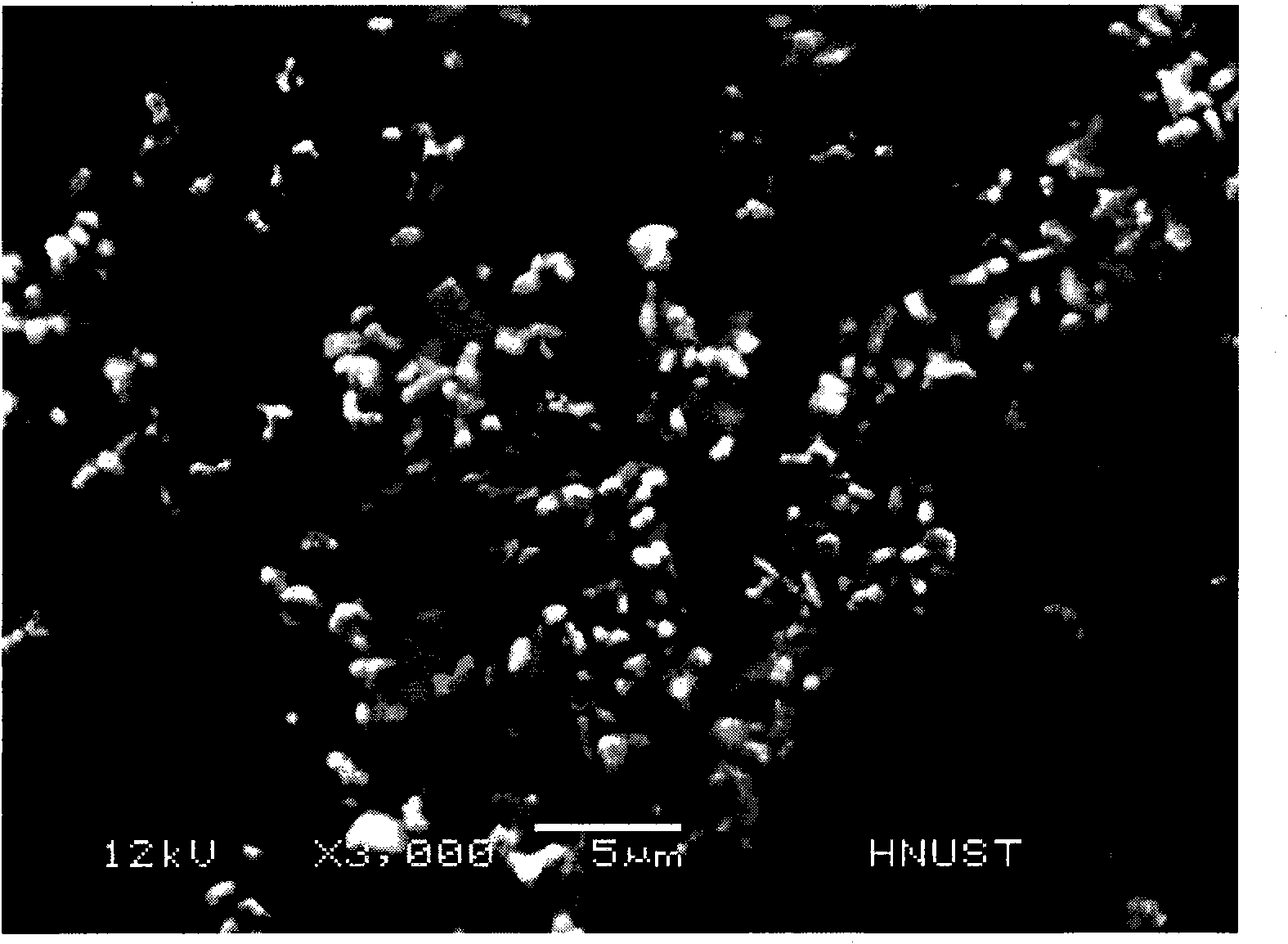

Embodiment 1

[0037] Embodiment 1: A microwave dielectric ceramic material with a medium dielectric constant and an ultra-high Q value

[0038] The raw material formula is composed of the following materials in mass percentage:

[0040] Aluminum oxide 10%;

[0042] Titanium Dioxide 35%.

[0043] The calcium carbonate, aluminum oxide, neodymium oxide and titanium dioxide are all analytically pure.

[0044] The preparation method is as follows: the synthesis process consists of the following steps in order:

[0045] The first step: after weighing calcium carbonate, alumina, neodymium oxide and titanium dioxide according to the raw material formula, place them in a zirconia ball mill, use deionized water as a solvent, and grind for 40 hours to obtain a uniformly mixed mixture;

[0046] The second step: in an infrared oven at a temperature of 105°C, dry the homogeneously mixed mixture obtained in the first step to remove deioniz...

Embodiment 2

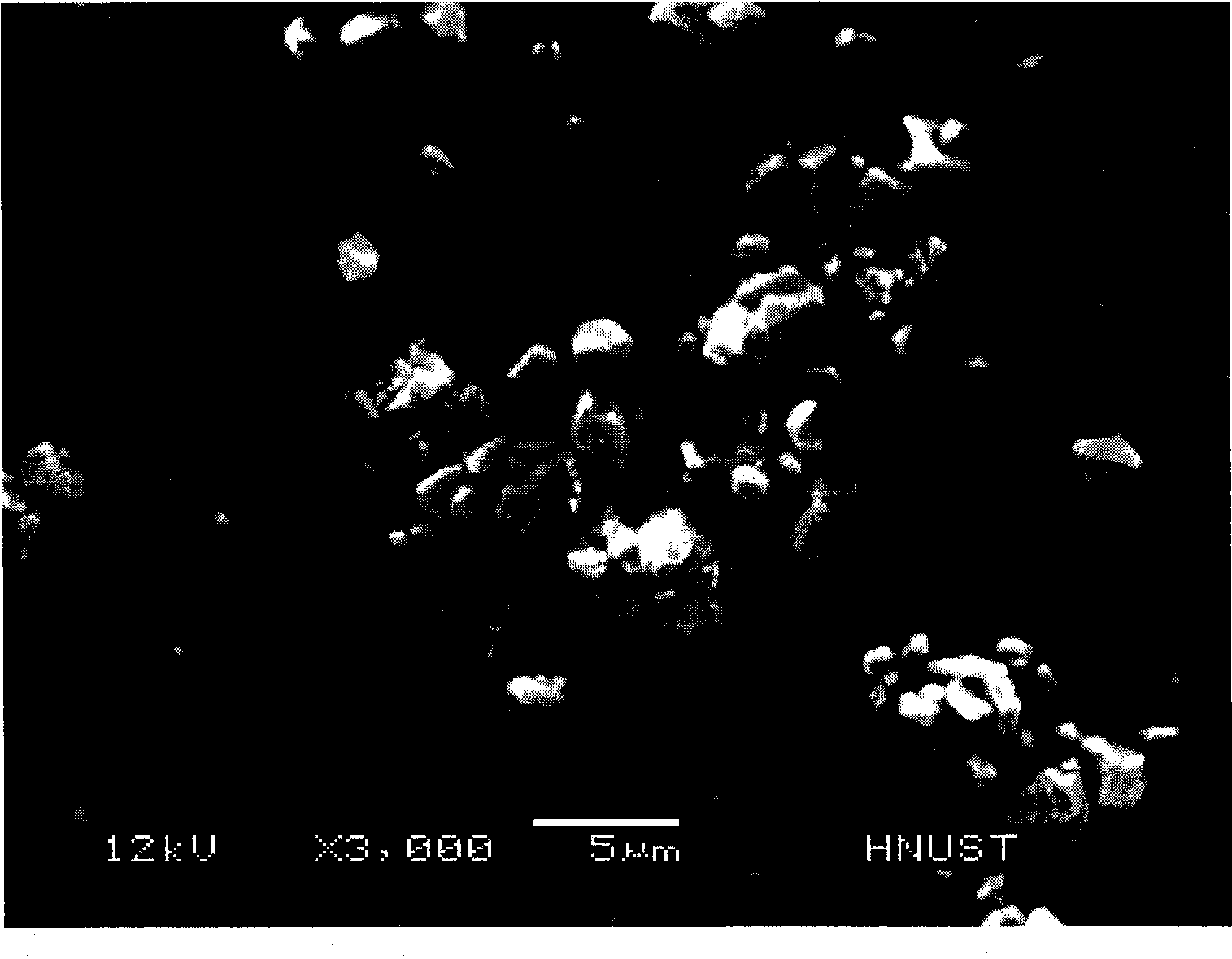

[0051] Example 2: A microwave dielectric ceramic material with a medium dielectric constant and an ultra-high Q value

[0052] The raw material formula is composed of the following materials in mass percentage:

[0054] Aluminum oxide 12%;

[0055] Neodymium oxide 25%;

[0056] Titanium dioxide 33%.

[0057] The calcium carbonate, aluminum oxide, neodymium oxide and titanium dioxide are all analytically pure.

[0058] The preparation method is as follows: the synthesis process consists of the following steps in order:

[0059] The first step: after weighing calcium carbonate, aluminum oxide, neodymium oxide and titanium dioxide according to the raw material formula, place them in a zirconia ball mill, use deionized water as a solvent, and grind for 55 hours to obtain a uniformly mixed mixture;

[0060] The second step: in an infrared oven at a temperature of 105°C, dry the uniformly mixed mixture obtained in the first step to remove deioniz...

Embodiment 3

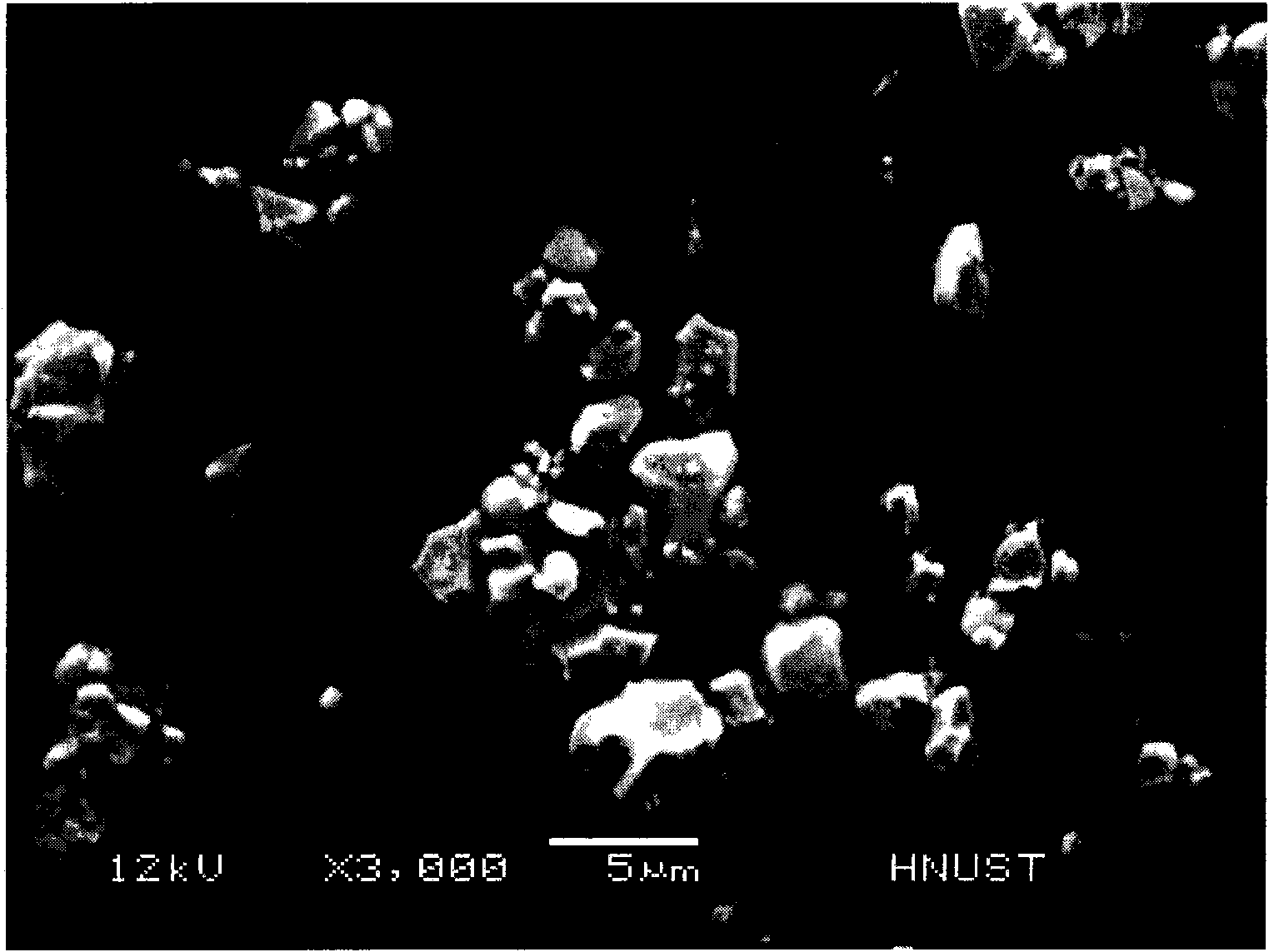

[0065] Embodiment 3: A microwave dielectric ceramic material with a medium dielectric constant and an ultra-high Q value

[0066] The raw material formula is composed of the following materials in mass percentage:

[0068] Aluminum oxide 12%;

[0069] Neodymium oxide 25%;

[0070] Titanium dioxide 30%.

[0071] The calcium carbonate, aluminum oxide, neodymium oxide and titanium dioxide are all analytically pure.

[0072] The preparation method is as follows: the synthesis process consists of the following steps in order:

[0073] The first step: after weighing calcium carbonate, alumina, neodymium oxide and titanium dioxide according to the raw material formula, place them in a zirconia ball mill, use deionized water as the medium, and grind for 48 hours to obtain a uniformly mixed mixture;

[0074] The second step: in an infrared oven at a temperature of 105°C, dry the uniformly mixed mixture obtained in the first step to remove deionized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency temperature coefficient | aaaaa | aaaaa |

| q value | aaaaa | aaaaa |

| q value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com