Scale high-speed composting treatment method of organic wastes

A technology of organic waste and treatment method, which is applied in the field of large-scale rapid composting treatment of organic waste, can solve the problems of incomplete fermentation, low degree of automation, and slow fermentation speed, etc., so as to improve the fermentation speed and automation degree, the effect of promoting the fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

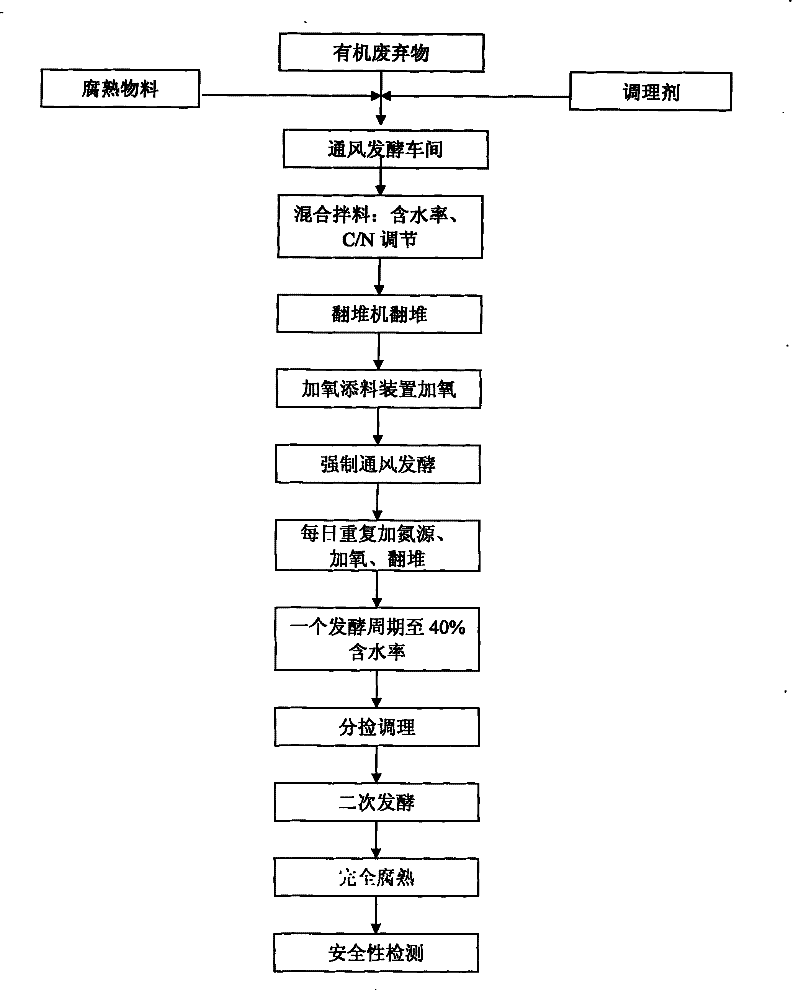

[0029] A large-scale fast composting method for organic waste, the steps of which are as follows:

[0030] (1) Use organic waste as fermentation substrate, reuse decomposed materials as strains and desiccant, add conditioner to reduce the moisture content of organic waste from 30%; conditioner can be straw, chaff, sawdust, mushroom Slag, bentonite, kaolin, zeolite powder, fly ash, blast furnace slag, phosphate fertilizer, phosphate rock powder, peat soil or lime, etc.;

[0031] (2) Transfer the material processed in step (1) into the ventilated fermentation workshop, and add 0.1% nitrogen source of gross weight to adjust the C / N of the fermentation material and increase the required nitrogen content of the fermentation bacteria through the feeding device. Nutrients and materials are subjected to forced-air static fermentation in a ventilated fermentation workshop;

[0032] (3) Compost and ferment the material processed in step (2) in a ventilated fermentation workshop, add a ...

Embodiment 2

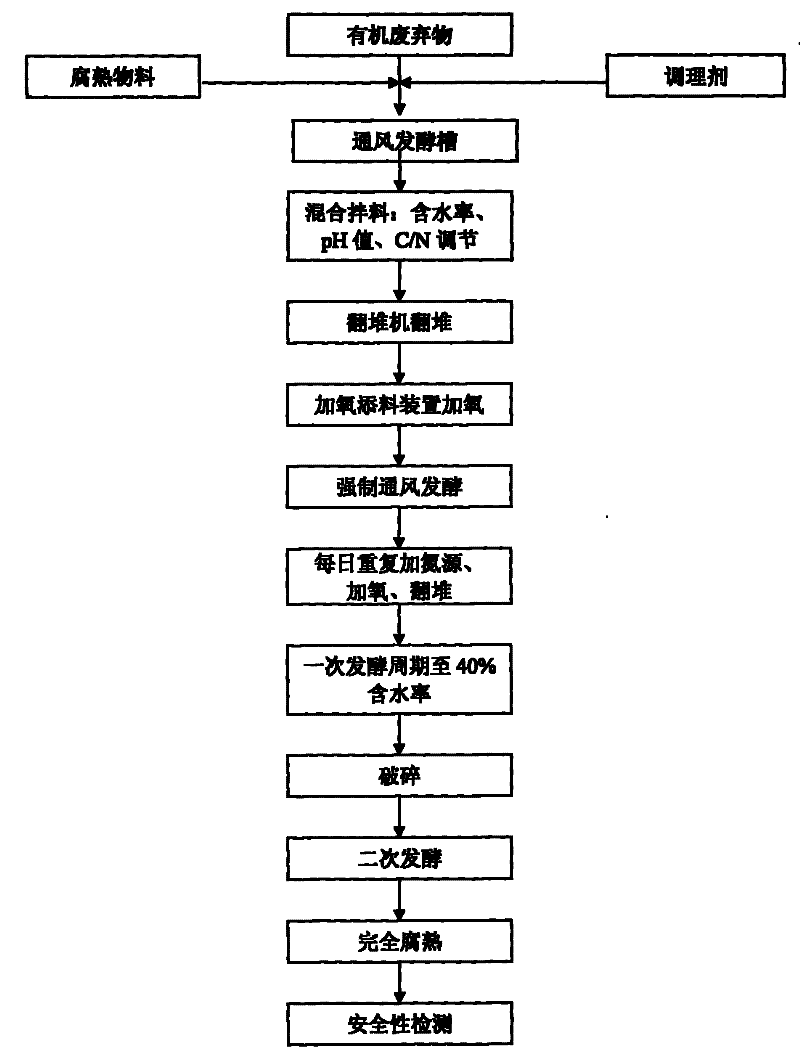

[0035] A large-scale fast composting method for organic waste, the steps of which are as follows:

[0036] (1) Use organic waste as fermentation substrate, reuse decomposed materials as strains and desiccant, add conditioner, and make the moisture content of organic waste 65%; conditioner can be straw, chaff, sawdust, mushroom residue , bentonite, kaolin, zeolite powder, fly ash, blast furnace slag, phosphate fertilizer, phosphate rock powder, peat soil or lime, etc.; the weight ratio of decomposed material + organic waste to conditioner can be 50-99:1-50.

[0037] (2) Transfer the material processed in step (1) into the ventilated fermentation workshop, add a nitrogen source of 20% of the total weight through the feeding device to adjust the C / N of the fermentation material and improve the life activity of the fermentation bacteria. Nutrients and materials are subjected to forced-air static fermentation in a ventilated fermentation workshop;

[0038] (3) Composting and ferme...

Embodiment 3

[0041] Such as figure 1 As shown, add decomposed material and conditioner to the organic waste, so that the ratio of organic waste: decomposed material: chaff: bentonite: zeolite powder is 70:70:3:18:3, and the moisture content is adjusted to about 50%. Then transfer to the ventilated fermentation workshop, add nitrogen source accounting for 10% of the total weight of the material through the solid fermentation oxygen addition device, adjust the pH value and C / N ratio, turn the compost by the compost turner, and then add oxygen by solid fermentation Oxygenation is added to the feeding device, and forced ventilation starts the composting process. On the second day, a nitrogen source accounting for 4% of the total weight of the material was added by a solid fermentation oxygenation and feeding device, and then turned by a compost turning machine, and then oxygenation was performed by a solid fermentation oxygenation and feeding device. On the third day, repeat the work of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com