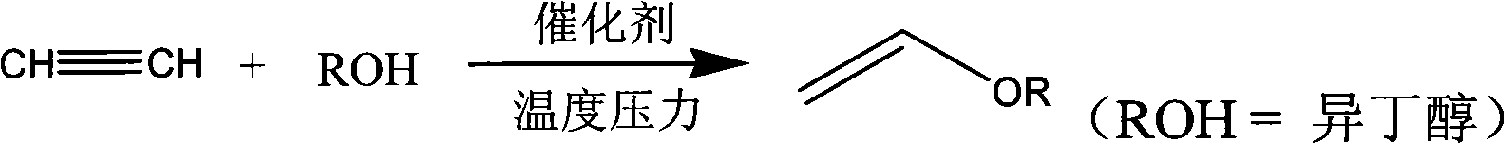

Synthesis method of isobutyl vinyl ether and device thereof

A technology of isobutyl vinyl ether and synthesis method, which is applied in the fields of ether preparation, unsaturated compound addition to ether, organic chemistry, etc., can solve the problems of high reactor manufacturing cost, high acetylene content, harsh reaction conditions, etc. Accelerate the reaction speed of etherification, high safety and reliability, clean production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

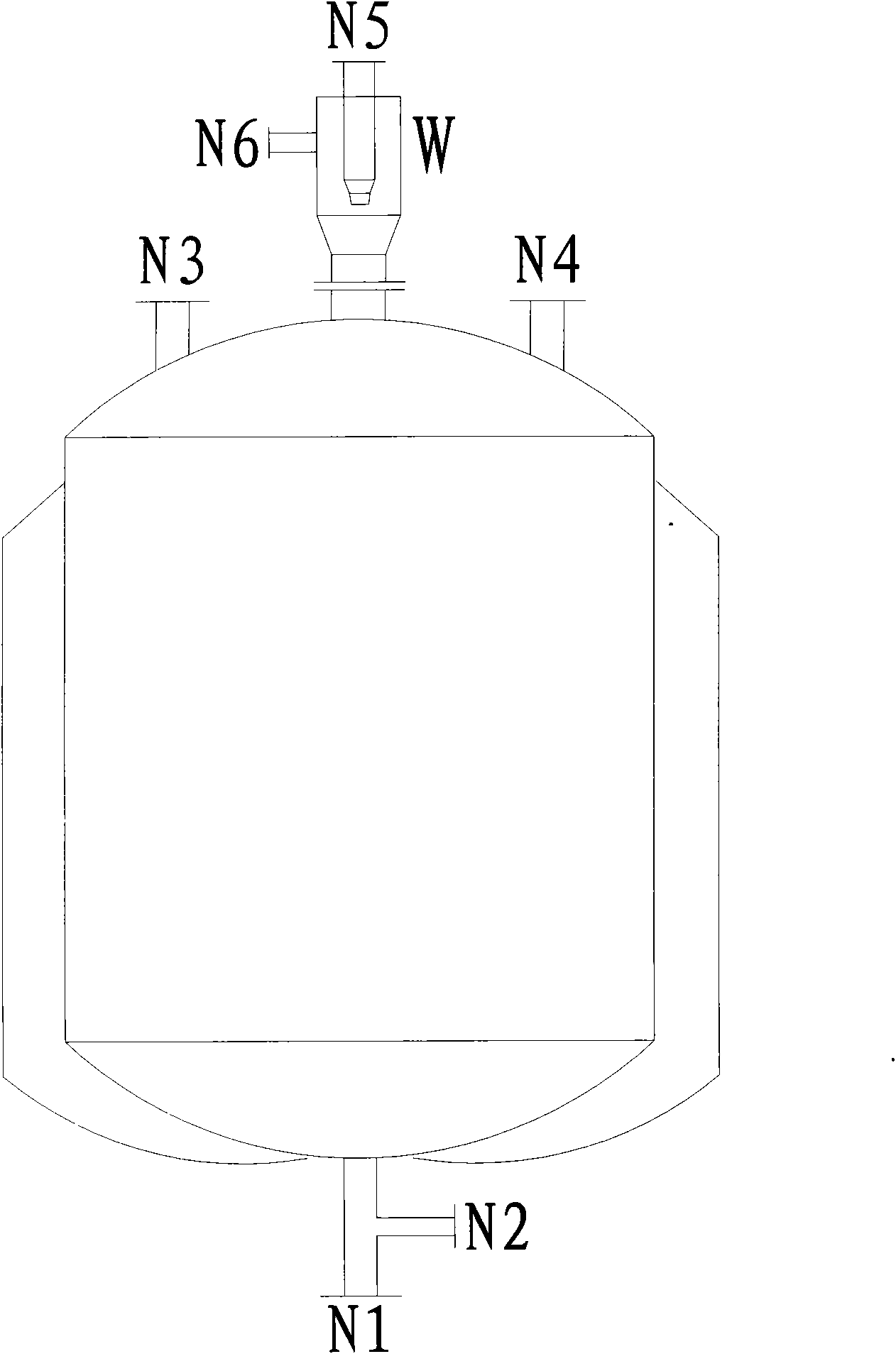

[0018] 1. Synthesis device: such as figure 1 As shown, the synthesis device of isobutyl vinyl ether is a stainless steel pressure-resistant kettle type reactor. The top of the kettle is equipped with a pressure-resistant venturi (W), a liquid feed port (N3) and a gas phase outlet (N4), and the bottom of the kettle is provided Circulating liquid outlet (N1) and catalyst outlet (N2), circulating liquid enters from the liquid phase inlet (N5) of the venturi (W), and acetylene gas is added through the gas phase inlet (N6) of the venturi (W).

[0019] 2. The specific operation steps are as follows:

[0020] Add a solution consisting of high boiling point auxiliary dimethylaniline, catalyst sodium alkoxide, and isobutanol into the autoclave reactor through the liquid feed port (N3) at one time, and replace with nitrogen before the acetylene is passed into the reactor. The air in the kettle keeps the nitrogen atmosphere in the kettle and keeps the nitrogen pressure in the kettle at 0.20M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com