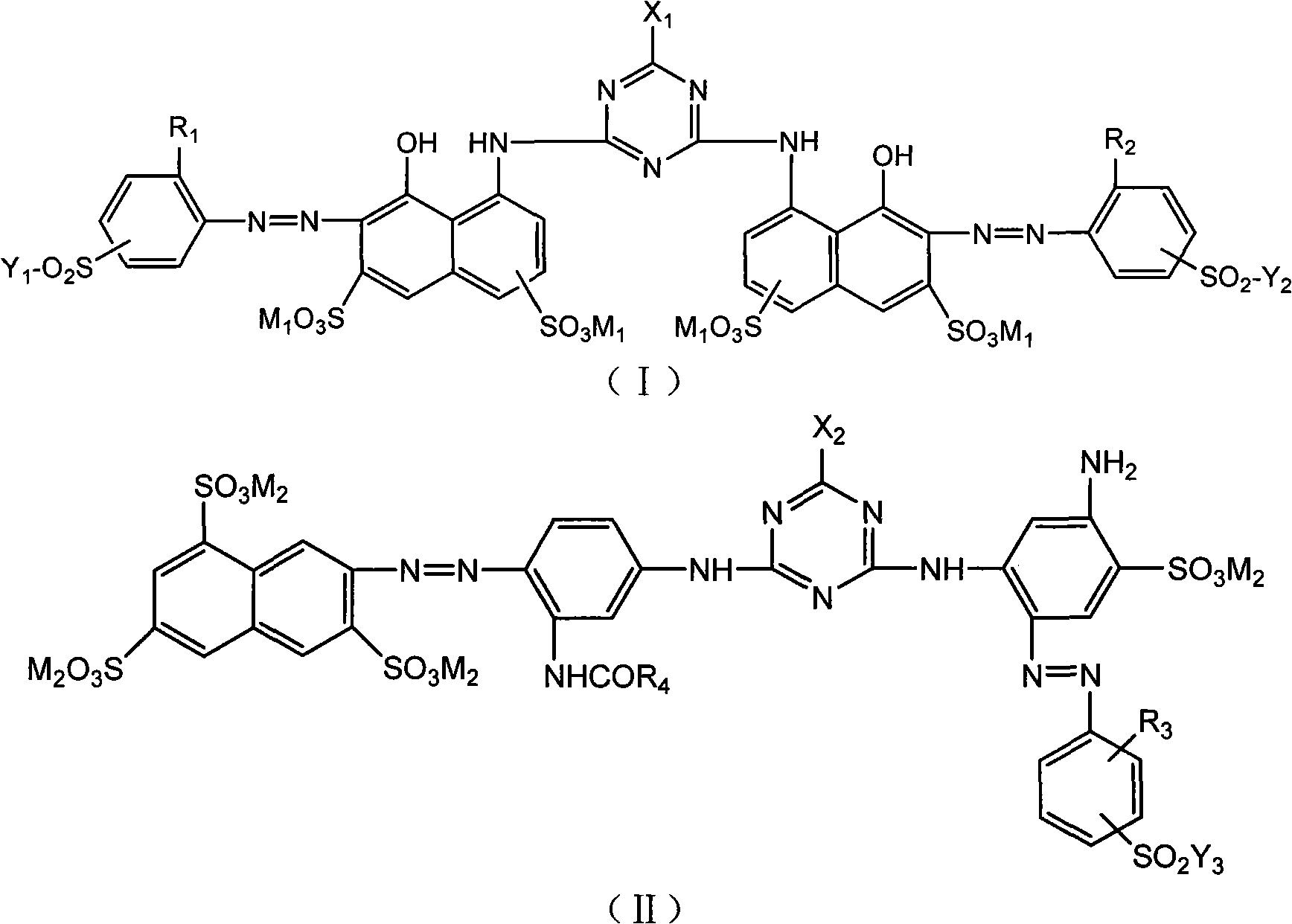

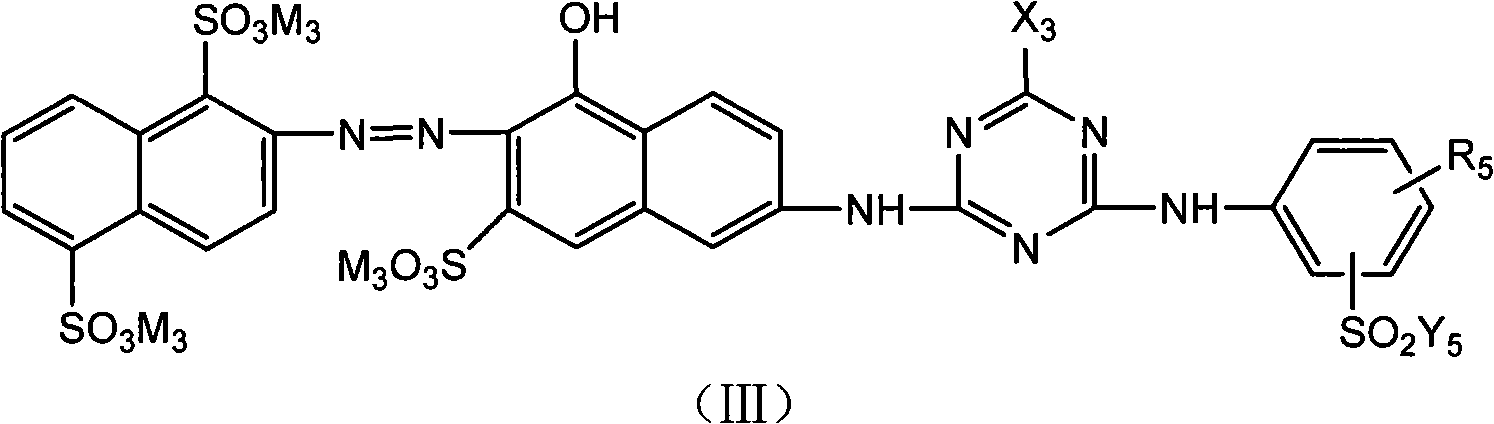

Active red dye composition

A technology of reactive red dye and composition, which is applied in the field of reactive red dye composition for textile printing and dyeing, can solve the problem that the low-salt dyeing effect of reactive dye is not reflected, and achieves small dyeing condition dependency, bright color and high color fixation rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

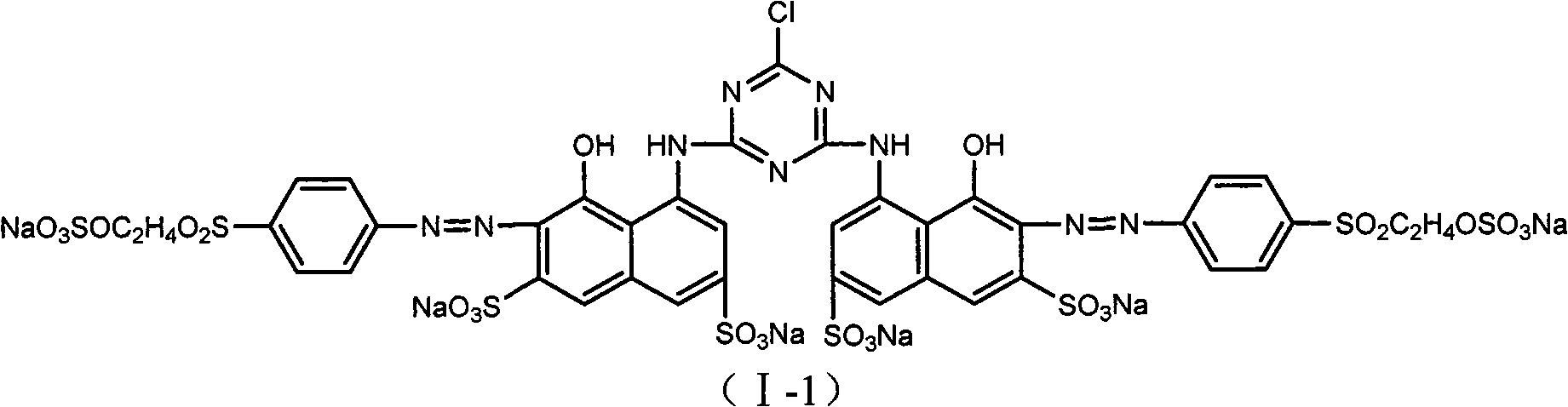

Embodiment 1

[0035] 80g synthetically obtained dye powder A of formula (I-1), 20g synthetically obtained dye powder B of formula (II-1) and 20g potassium chloride powder are mechanically blended and applied to cotton fiber dyeing to obtain bright-coloured red tint.

[0036] Dyeing method: Dissolve 2g of the composite reactive dye powder prepared above in 400g of water, add 1500g (containing 50g of Yuanming powder) aqueous solution, add 100g of cotton fiber to the dye solution at 40°C for dyeing, after 50 minutes, add 100g (containing 8g sodium hydroxide and 10g sodium carbonate) in water. Keep the dye solution at 80°C for 50 minutes to fix the color. Then rinse the dyed matter, soap it with non-ionic detergent for 15 minutes, then rinse and dry it to get a bright red cotton cloth with good dyeing property and excellent color fastness.

[0037]

Embodiment 2

[0039] The dye powder A of 75g formula (I-2), the dye powder B of 25g formula (II-2) and 20g potassium chloride powder are carried out mechanical blending, then apply to cotton fiber dyeing according to embodiment 1 dyeing method, can obtain Vibrant red shade.

[0040]

[0041]

Embodiment 3~20

[0043] According to the blending method described in Example 1, the difference is that the dye A, dye B and weight ratio shown in the following table 1 are adopted, in addition, the addition of potassium chloride is 25% of the total weight of the dye, Apply to cotton fiber dyeing according to embodiment 1 dyeing method, also can obtain bright red tone.

[0044] Table 1

[0045] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com