Light and thin type self-lubricating bearing and manufacturing method thereof

A technology for self-lubricating bearings and manufacturing methods, applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of complex copper powder sintering process, difficult quality control, high product cost, etc., to achieve environmental protection and reduce energy consumption , save the effect of copper powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

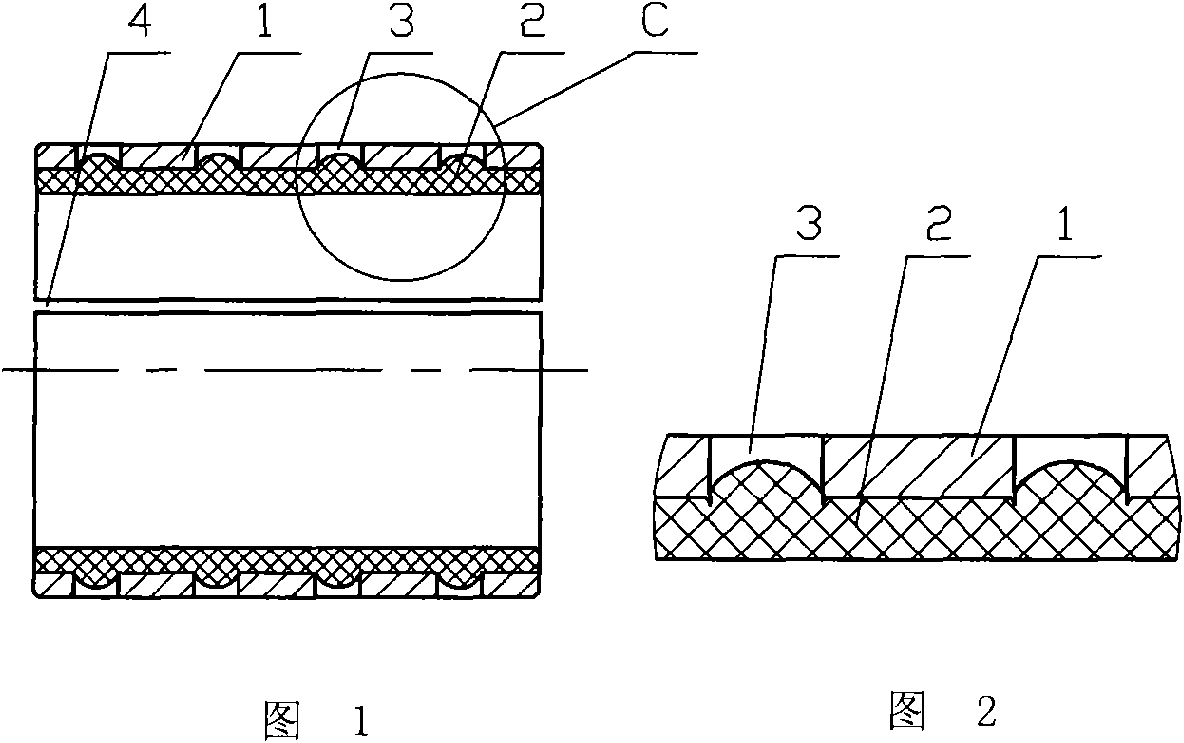

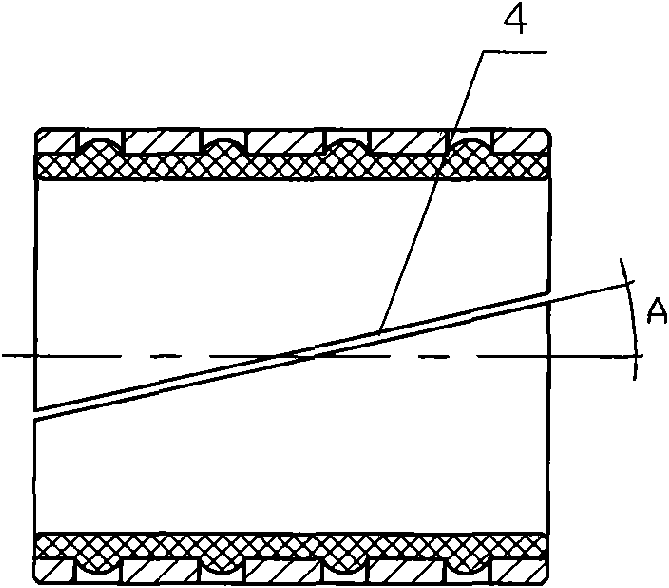

[0038] The manufacturing method of light and thin self-lubricating bearing has the following steps:

[0039] A. Preparation of non-metallic wear-resistant materials:

[0040] (1) Ingredients: by volume percentage, polytetrafluoroethylene 80%, graphite 10% and glass fiber 10%;

[0041] (2) Abrasives and mixing materials: Grind the above-mentioned ingredients finely, the diameter of the particles is 15 μm, and the aspect ratio of the glass fiber is 4:1-6:1, mix and stir evenly to form a mixture;

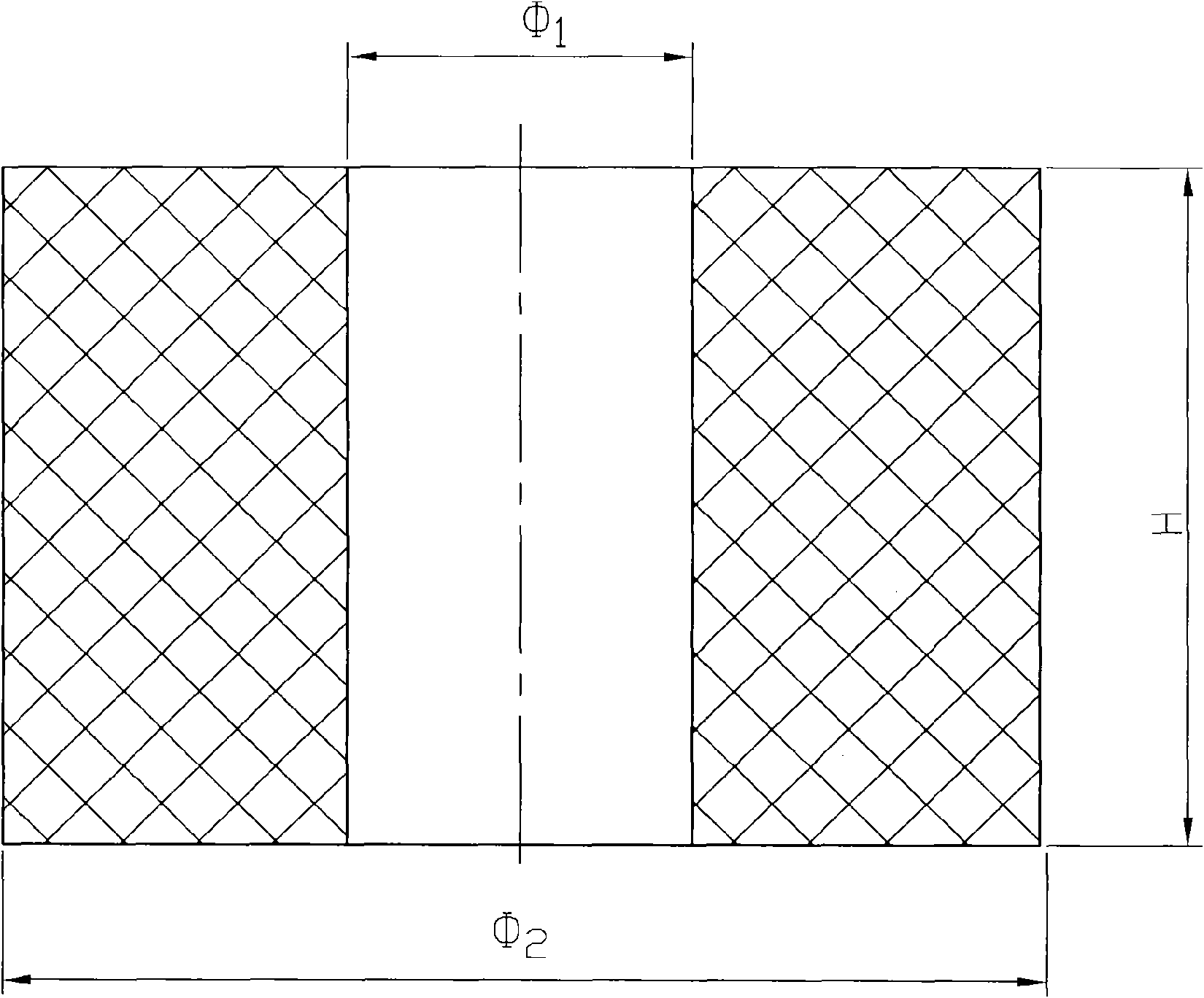

[0042] (3) Pressing and forming: put the mixture into a cylindrical mold such as Figure 4 As shown, the pressure is 36MPa, so that the volume ratio of the natural state of the mixture to the compressed state is 3.8, and it is pressed into a cylindrical blank with a hole in the middle, such as Figure 5 shown;

[0043] (4) Sintered billet: put the billet into the heating furnace and gradually increase from natural temperature to 360°C → drop to 120°C → rise to 360°C → drop to 120°C ...

Embodiment 2

[0056] The manufacturing method of light and thin self-lubricating bearing has the following steps:

[0057] A. Preparation of non-metallic wear-resistant materials:

[0058] (1) Ingredients: by volume percentage, polytetrafluoroethylene 83%, molybdenum disulfide 12% and aromatic fiber 5%;

[0059] (2) Abrasives and mixing materials: Grind the above-mentioned ingredients until the particle size is less than 20 μm, mix and stir evenly to form a mixture;

[0060] (3) Pressing, forming: the mixture is put into a cylindrical mold, pressurized at 38MPa, so that the volume ratio of the volume in the natural state of the mixture to the compressed state is 4, and it is pressed into a cylindrical blank with a hole in the middle;

[0061] (4) Sintered billet: Put the billet into the heating furnace and gradually increase from natural temperature to 360°C → drop to 120°C → rise to 360°C → drop to 120°C →, one cycle of temperature rise and fall, 9 consecutive cycles, The total time is 7...

Embodiment 3

[0074] The manufacturing method of light and thin self-lubricating bearing has the following steps:

[0075] A. Preparation of non-metallic wear-resistant materials:

[0076] (1) Ingredients: by volume percentage, polytetrafluoroethylene 70%, tungsten disulfide 18%, carbon fiber 12%;

[0077] (2) Abrasives and mixing materials: Grind the above-mentioned ingredients finely, the size of the particles is less than 15 μm, and the aspect ratio of the carbon fiber is 4:1-6:1, mix and stir evenly to form a mixture;

[0078] (3) pressing, forming: the mixture is put into a cylindrical mould, pressurized to 40MPa, so that the volume ratio of the natural state volume of the mixture to the compressed state is 4.2, and it is pressed into a cylindrical blank with a hole in the middle;

[0079] (4) Sintered billet: Put the billet into the heating furnace and gradually increase from natural temperature to 360°C → drop to 120°C → rise to 360°C → drop to 120°C →, one cycle of temperature rise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com