One-step preparation method for synthesizing black expandable polystyrene particles

A technology of expandable polystyrene and polystyrene particles, which is applied in the field of preparation of expandable polystyrene particles, can solve problems such as increasing the extrusion granulation process, and achieves lower cost, lower polymerization inhibition and reaction low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

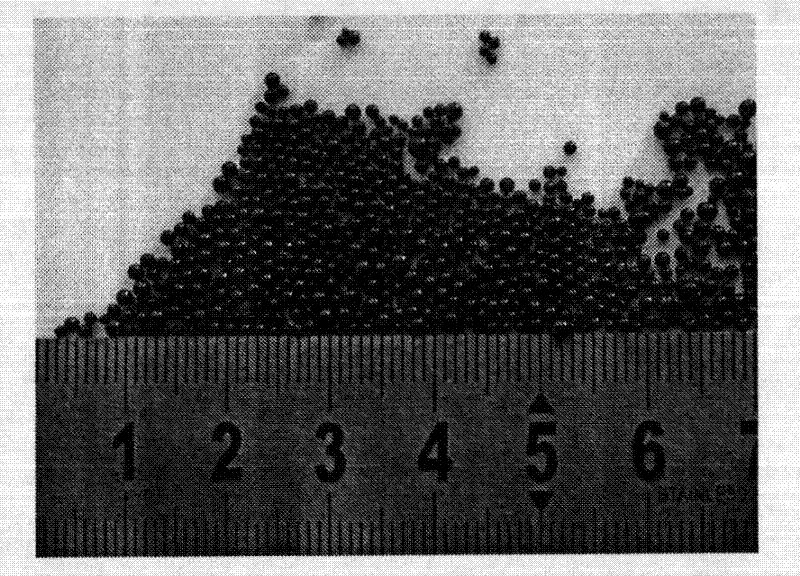

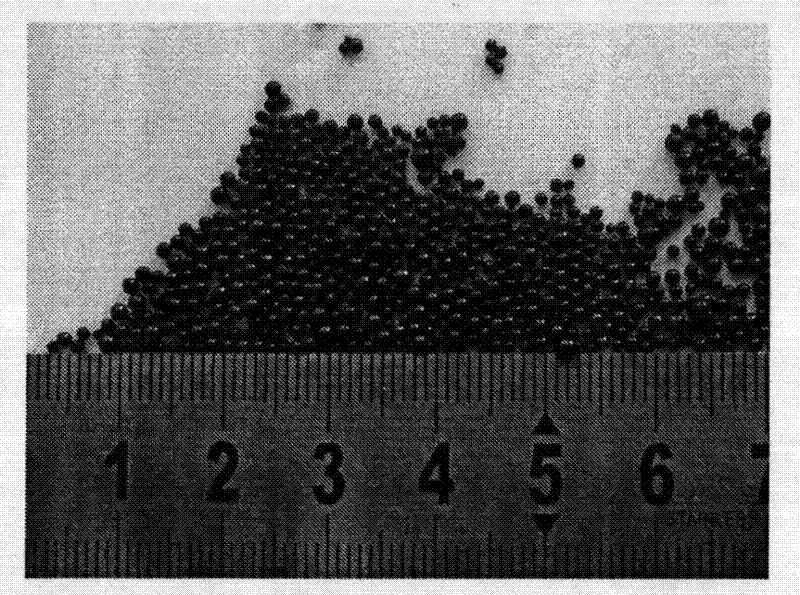

Image

Examples

preparation example Construction

[0022] A preparation method for synthesizing black expandable polystyrene particles by one-step method comprises the following steps:

[0023] Carbon black pretreatment:

[0024] According to carbon black: surfactant: deionized water = 1-2: 2-1: 40-50 (mass ratio), feed into a four-neck round bottom flask, heat in an automatic temperature-controlled water bath to maintain 70-85 ° C, and stir for 12 hours , washed with water, vacuum-filtered, and vacuum-dried for later use.

[0025] Synthesis of black expandable polystyrene particles:

[0026] a According to the percentage of monomer mass, add 0.2-0.5% of organic dispersant polyvinyl alcohol and 350-500% of deionized water into the autoclave, stir mechanically, keep the stirring speed at 210-350 rpm, and heat it in a water bath to 85- After the polyvinyl alcohol is fully dissolved at 93°C, cool down to 30-50°C and keep for 10-20 minutes, then add 1-2% of anhydrous sodium sulfate as an inorganic dispersant;

[0027] b Mix 0.2...

Embodiment 1

[0032] Pretreatment of carbon black: 1.5 grams of carbon black; 1.5 grams of sodium dodecylbenzene sulfonate; 50 milliliters of deionized water were fed into a four-necked round-bottomed flask, heated in an automatic temperature-controlled water bath to maintain 70 ° C, and stirred for 12 hours. Wash with water, vacuum filter, and vacuum dry for later use.

[0033] Synthesis of black expandable polystyrene particles: Add 0.14 g of polyvinyl alcohol and 210 ml of deionized water to the autoclave in sequence, keep the stirring speed of a mechanical stirrer at 300 rpm, and heat to 92°C in an automatic temperature-controlled water bath After the polyvinyl alcohol is fully dissolved, cool down to 30°C, add 0.90 g of anhydrous sodium sulfate as an inorganic dispersant, and then add the mixed solution containing 0.12 g of modified light carbon black and 20 ml of deionized water dispersed by ultrasonic to In the reaction kettle, keep stirring at 30°C for 20 minutes so that the modifie...

Embodiment 2

[0036] Pretreatment of carbon black: 1.5 grams of carbon black; 1.5 grams of sodium dodecylsulfonate; 50 milliliters of deionized water were fed into a four-neck round bottom flask, heated in an automatic temperature-controlled water bath to maintain 80 ° C, stirred for 12 hours, and washed with water Vacuum filtration, vacuum drying for later use.

[0037] Synthesis of black expandable polystyrene particles: 0.15 g of polyvinyl alcohol and 215 ml of deionized water were added to the autoclave in sequence, the stirring speed of the mechanical stirrer was kept at 280 rpm, and the automatic temperature control water bath was heated to 93°C After fully dissolving the polyvinyl alcohol, lower the temperature to 35°C, add 0.80 g of activated calcium phosphate, and then add the ultrasonically dispersed mixture containing 0.20 g of modified light carbon black and 20 ml of deionized water into the autoclave , keep stirring at 35°C for 20 minutes to make the modified carbon black bette...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com