A kind of magnetic graphite/polystyrene bead that reduces polymerization resistance and preparation method thereof

A technology of polystyrene pellets and polyvinylpyrrolidone, applied in the field of magnetic graphite/polystyrene pellets and its preparation, can solve problems such as difficult collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

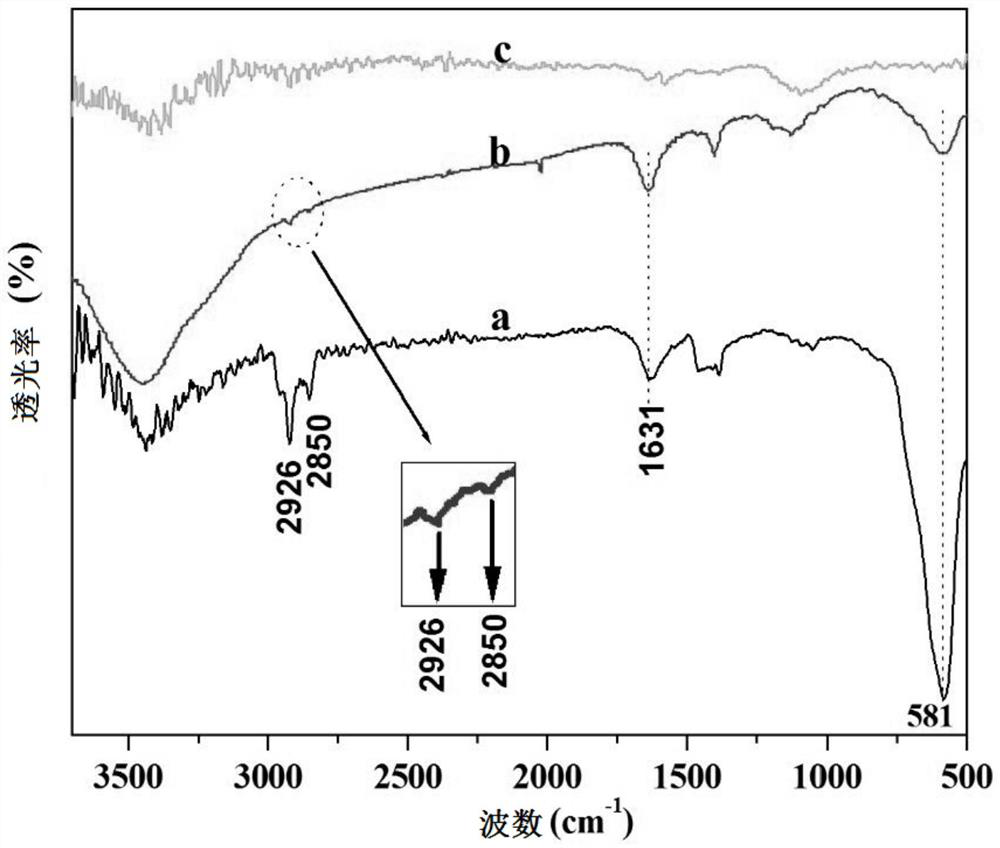

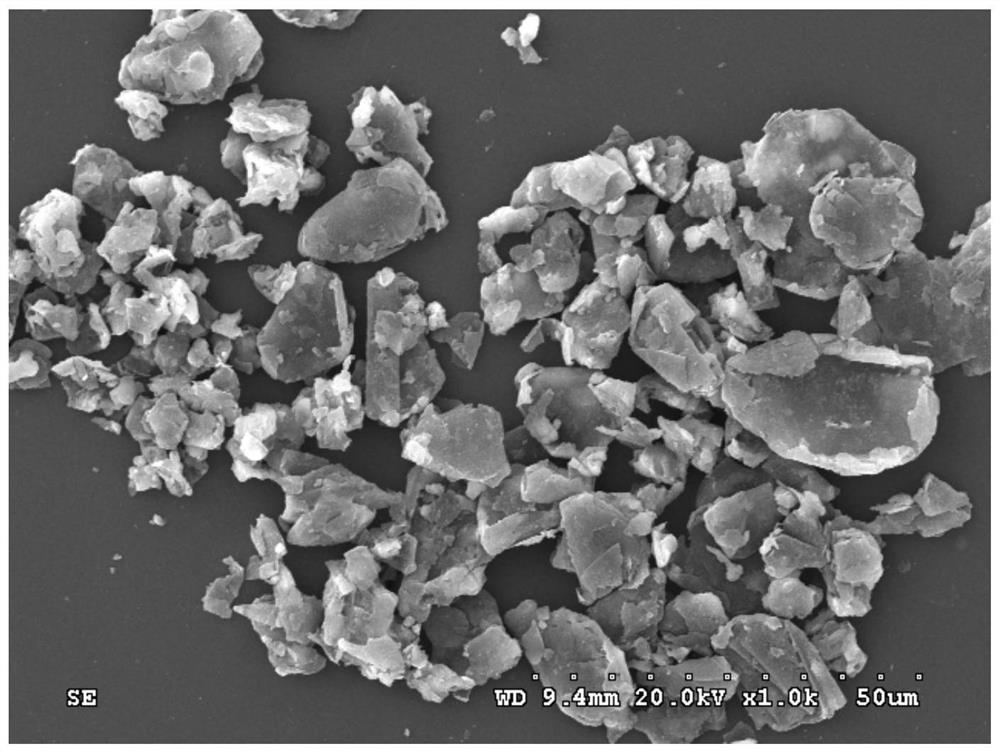

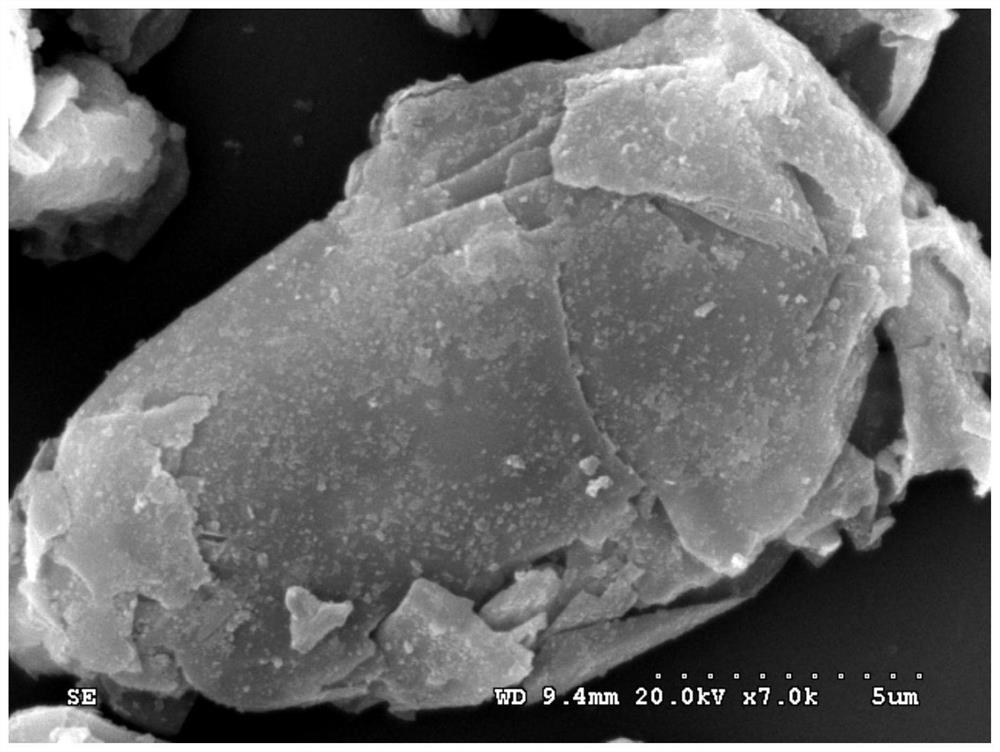

[0047] 1) Preparation of magnetic graphite with reduced inhibition of polymerization

[0048] Add 0.6g of polyvinylpyrrolidone and 100mL of distilled water to a three-necked flask equipped with a stirring paddle and a condenser tube. After stirring and dissolving, add 6.0g of graphite powder, stir to disperse evenly, and then mix according to the molar ratio of Fe 3+ : Fe 2+ =2:1 Add 4 mmol of ferric chloride and 2 mmol of ferrous chloride, and stir for 60 min to dissolve them. Adjust the rotation speed to 320rpm, add ammonia water to the above reaction system within 3 seconds to make the pH of the system 11, then heat in a water bath to 78°C, react for 45min, cool to room temperature, magnetically separate, wash with water until neutrally dispersed in 100mL of distilled water, Then, add 0.4g hydrophobic modifier oleic acid and 2.0mL ethanol, stir at 180rpm, heat in a water bath at 65°C, react for 40min, cool to room temperature, magnetically separate and dry to obtain hydrop...

Embodiment 2

[0051] 1) Preparation of magnetic graphite with reduced inhibition of polymerization

[0052] Add 0.7g of polyvinylpyrrolidone and 100mL of distilled water to a three-necked flask equipped with a stirring paddle and a condenser tube. After stirring and dissolving, add 7.0g of graphite powder, stir to disperse evenly, and then mix according to the molar ratio of Fe 3+ : Fe 2+ =2:1 Add 2 mmol of ferric sulfate and 2 mmol of ferrous sulfate, and stir for 8 min to dissolve them. Adjust the rotation speed to 350rpm, add ammonia water to the above reaction system within 3 seconds to make the pH of the system 11, then heat in a water bath to 79°C, react for 70min, cool to room temperature, magnetically separate, wash with water until neutrally dispersed in 100mL of distilled water, Then, add 0.7g of hydrophobic modifier vinyltrimethoxysilane and 2.0mL of ethanol, stir at 180rpm, heat in a water bath at 65°C, react for 65min, cool to room temperature, and dry by magnetic separation ...

Embodiment 3

[0055] 1) Preparation of magnetic graphite with reduced inhibition of polymerization

[0056] Add 1.0g of polyvinylpyrrolidone and 120mL of distilled water to a three-necked flask equipped with a stirring paddle and a condenser tube. After stirring and dissolving, add 8.0g of graphite powder, stir to disperse evenly, and then mix according to the molar ratio of Fe 3+ : Fe 2+ =2:1 Add 5 mmol of ferric nitrate and 2.5 mmol of ferrous nitrate, stir for 10 min to dissolve. Adjust the rotation speed to 360rpm, add the aqueous solution of sodium hydroxide to the above reaction system within 3 seconds to make the pH of the system 11.5, then heat the water bath to 80°C, react for 75min, cool to room temperature, magnetically separate, wash with water until neutrally dispersed in 100mL of distilled water, and sonicate in an ultrasonic cleaner for 11min, then add 0.8g of hydrophobic modifier methyltriethoxysilane and 2.5mL of ethanol, stir at 200rpm, heat in a water bath at 75°C, react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com