Cracking type biomass gasifier in tar furnace

A biomass and gasifier technology, which is applied in the petroleum industry, combined combustion mitigation, and the manufacture of combustible gas, can solve the problems of increased manufacturing cost, increased pressure in the pyrolysis zone, easy smoke, etc., and can improve the conversion rate and Gas calorific value, reduction of tar content, effect of low tar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific implementation of the pyrolysis type biomass gasifier in the tar furnace of the present invention will be further described below in conjunction with the accompanying drawings.

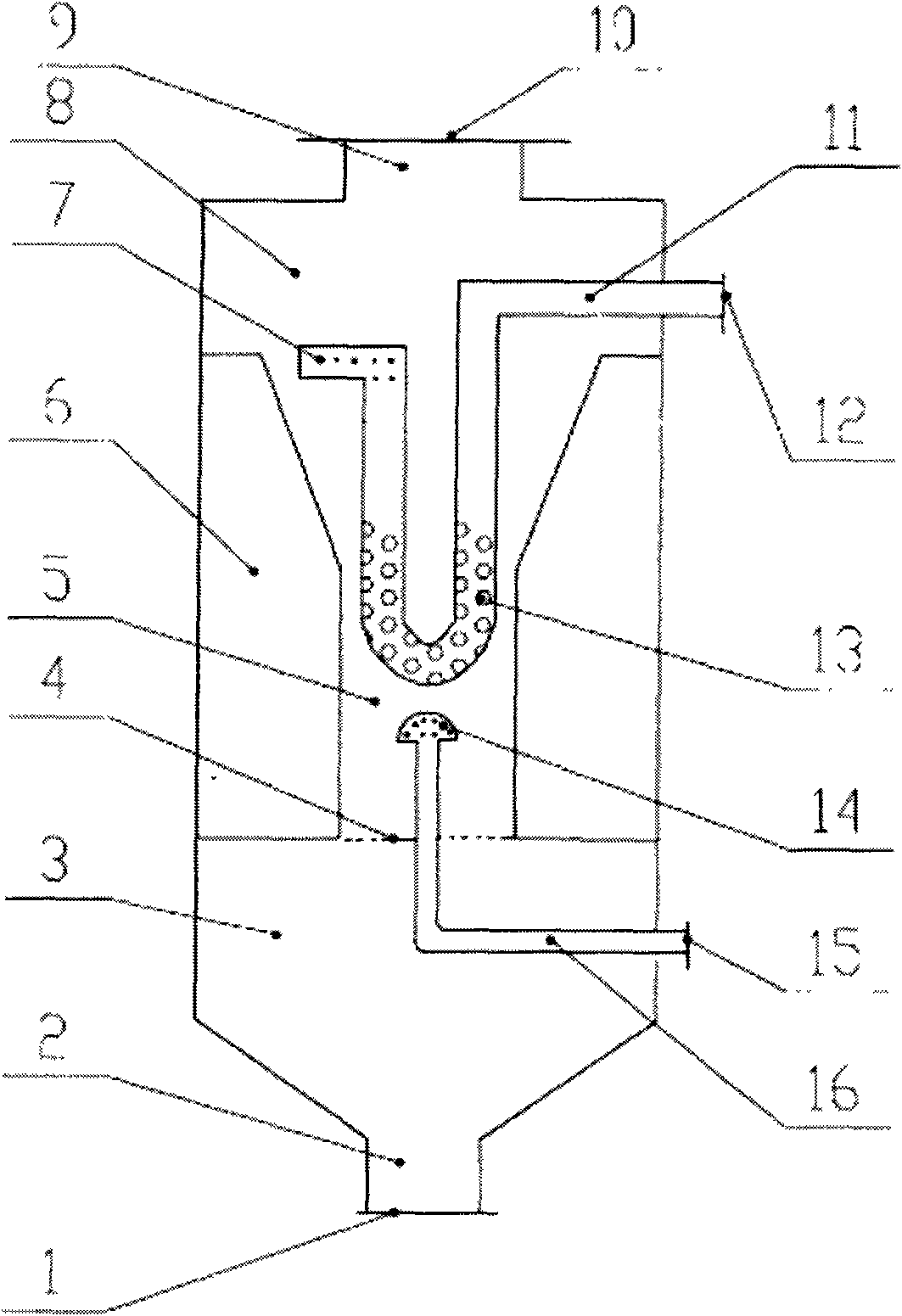

[0009] Cracking type biomass gasification furnace in tar furnace of the present invention such as figure 1 As shown, it includes lower furnace door (1), ash outlet (2), ash bin (3), fire grate (4), combustion chamber (5), heat preservation bin (6), gas inlet (7), feed bin (8), feed inlet (9), furnace cover (10), gas pipeline (11), gas outlet (12), porous medium (13), secondary air inlet (14), primary air inlet (15), Air duct (16). The gas primary outlet (7), the porous medium (13), the gas pipeline (11), and the gas outlet (12) form a gas delivery pipeline, which is installed in the feed bin (8); the gas delivery pipeline is a U-shaped pipe or a spiral coil . The porous medium is heat storage ceramic material or tar catalyst material such as dolomite, olivine, clay ore, charcoal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com