Arachidonic acid and methods for the production and use thereof

A technology for biomass, oils, and applications in biochemical equipment and methods, fatty acid production, microorganism-based methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

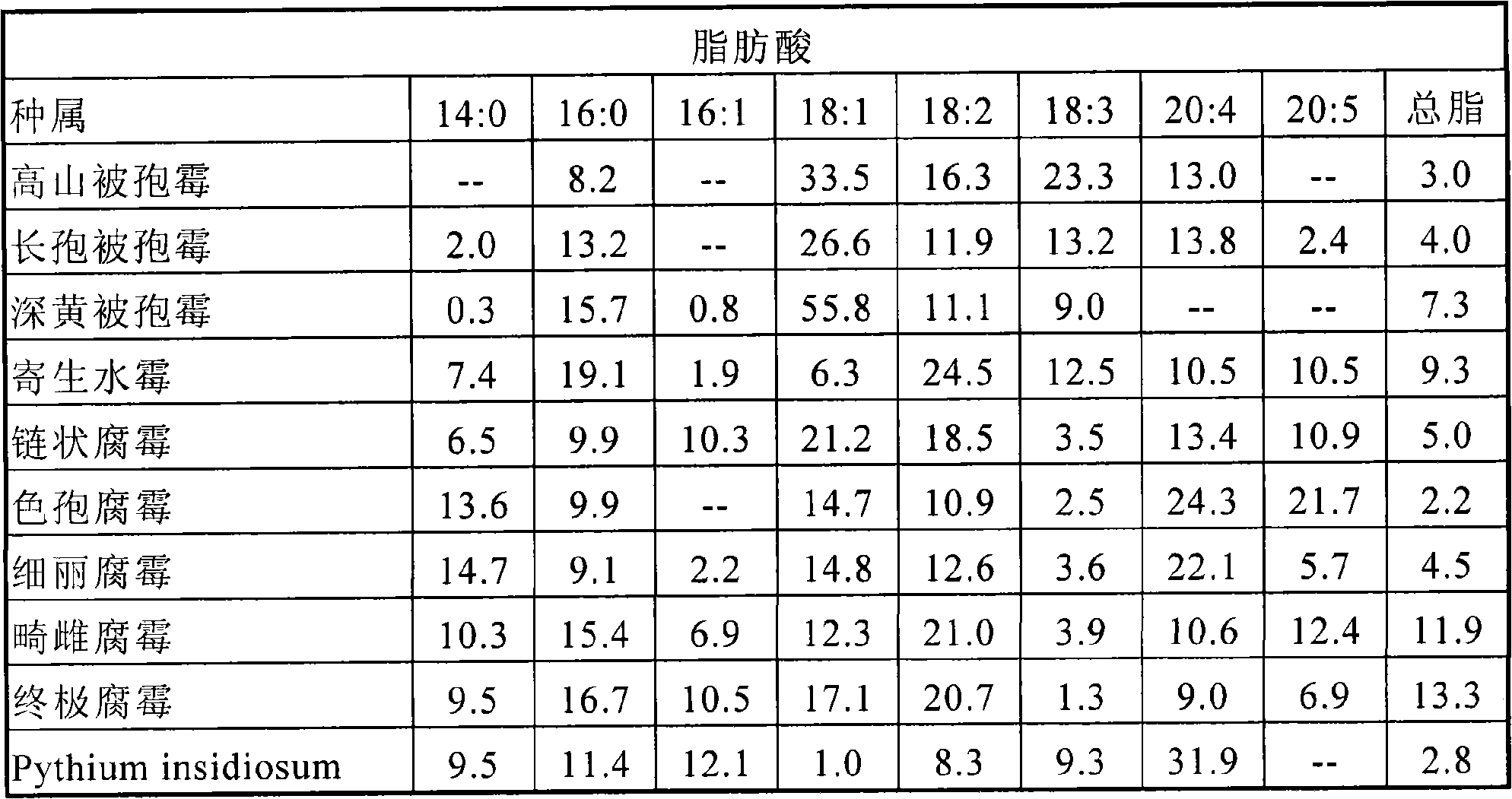

[0083] Example 1. Prepare P.insidiosum fat and add to infant formula

[0084] In an 80L (approximate volume) fermenter, mix 51L of tap water, 1.2kg of glucose, 240g of yeast extract and 15ml of MAZU defoamer. The fermenters were sterilized at 121°C for 45 minutes. Add another 5L of condensed water during the sterilization process. Adjust the pH to 6.2, then add about 1 L (with a cell density of 5-10 g / l) of Python insidiosum (ATCC #28251) Inoculum. The stirring speed was adjusted to 125 RPM (250 cm / sec rim speed) and the aeration rate was set to 1 SCFM (standard cubic feet per minute). At 24 hours, increase the ventilation rate to 3 SCFM. In the 48th hour, another 2 L of 50% glucose syrup (1 kg glucose) was added. In the 50th hour, the tank was harvested, and the output was about 2.2kg wet weight (about 15g dry weight) / L. The harvested biomass was pressed into a high solids (50% solids) cake on a suction filter and then freeze-dried. The dried biomass was pulveri...

Embodiment 2

[0085] Example 2. Preparation of Mortierella alpina fat and addition to infant formula

[0086] Mortierella alpina (ATCC #42430) was grown in a 2L shake flask containing 1L of tap water and 2g of potato dextrose medium. The shake flask was kept at 25°C with rotary stirring for 7 days. After the biomass was harvested by centrifugation, it was freeze-dried to obtain about 8 g of liposome-rich mycelia. The mycelia were extracted with hexane as described in Example 1 to obtain about 2.4 g of crude oil. This oil contains about 23% arachidonic acid and is added to commercially available infant formula products at a concentration of 100mg / L middle.

Embodiment 3

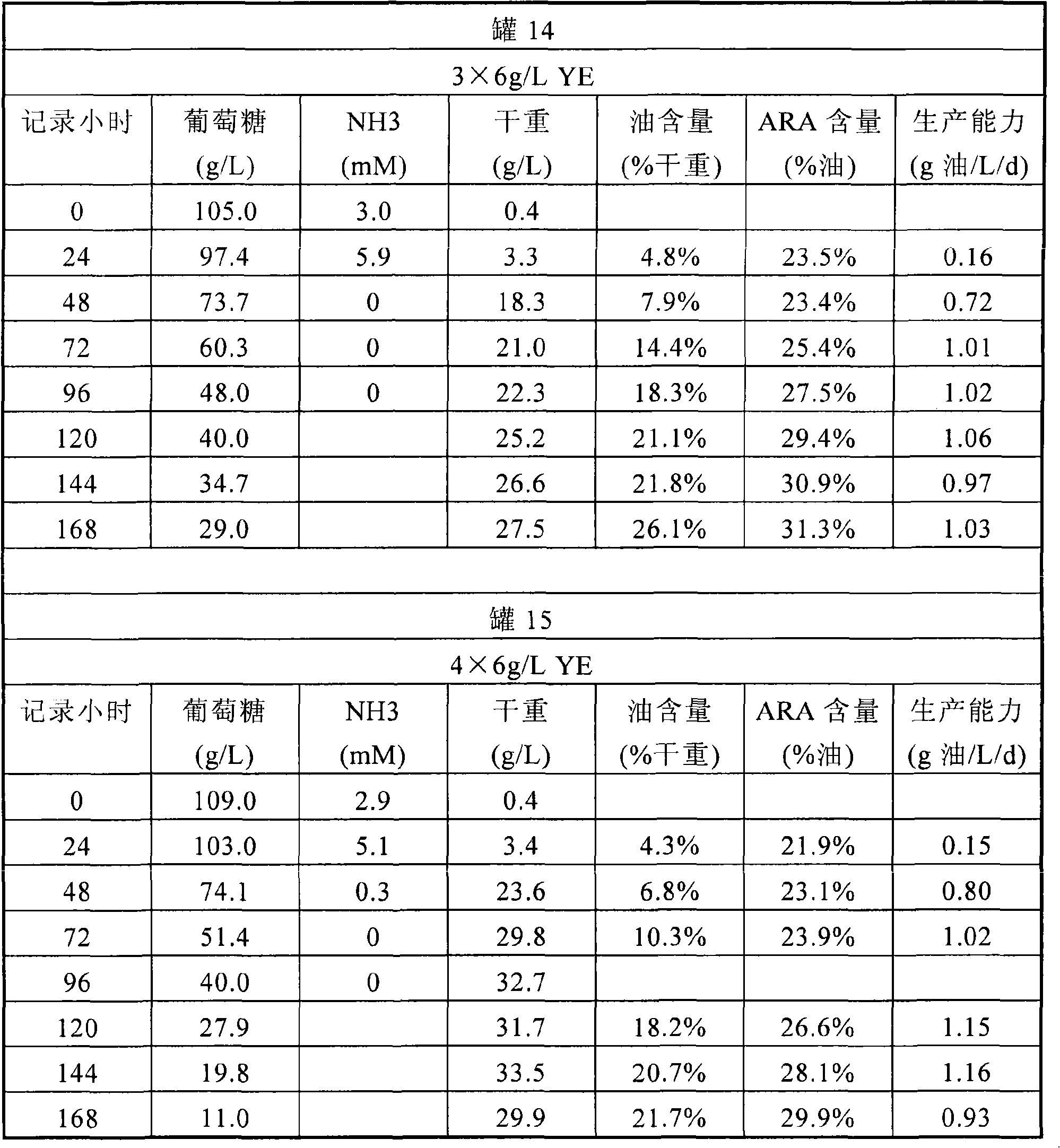

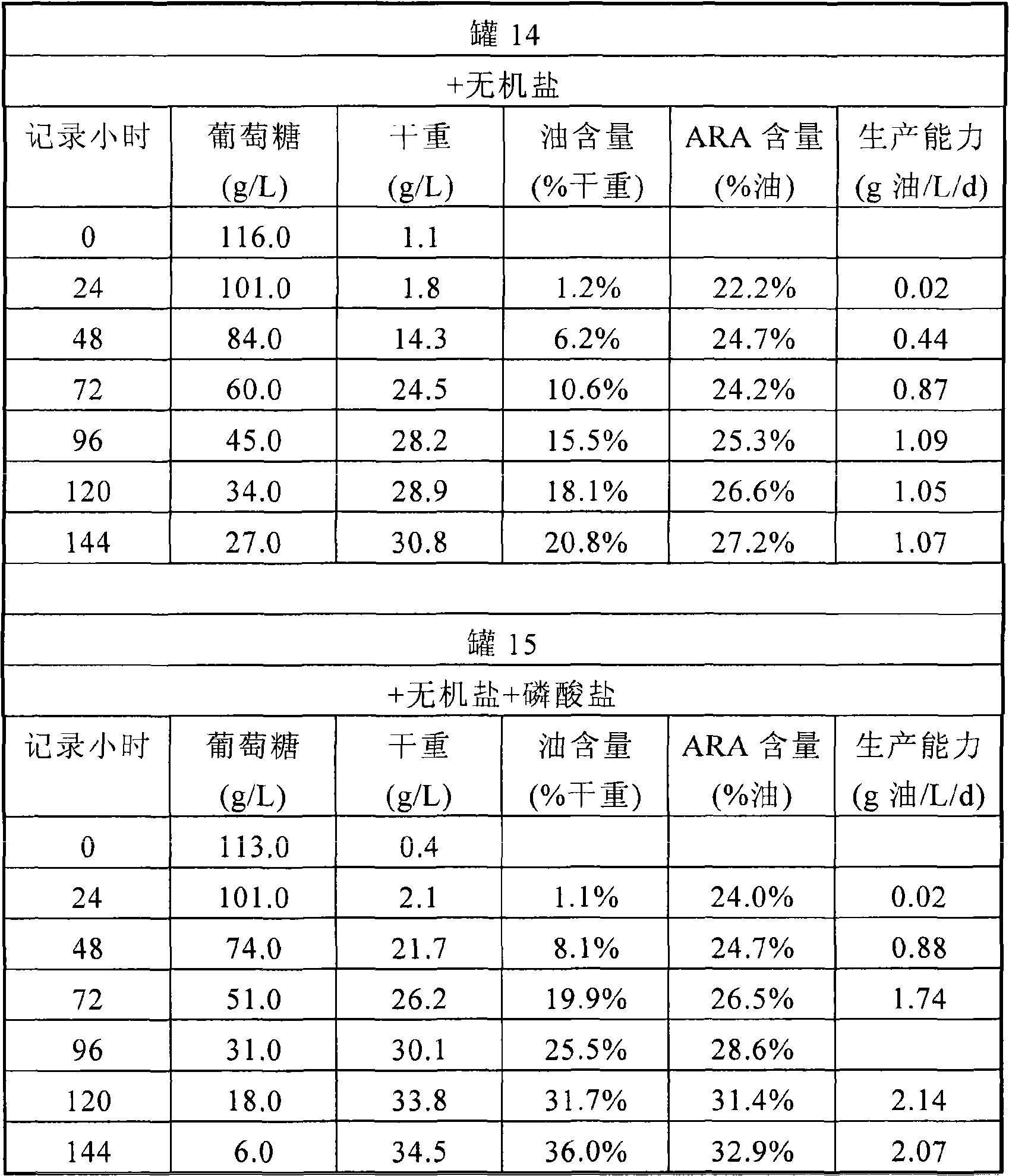

[0087] Example 3. Mass production of arachidonic acid by Mortierella alpina

[0088] Inoculate Mortierella alpina into inoculation tanks containing GYE medium (50 g / L glucose and 6 g / L Tastone 154). The fermentation temperature was set at 28° C., the initial stirring speed was 130-160 cm / sec, the initial tank pressure was 6 psi, and the initial aeration rate was 0.25 VVM. The pH was adjusted to 5.0 before sterilization and to 5.5 for the initial fermentation after sterilization. The pH of the medium was maintained at ≥ 5.5 with 8N NaOH. Adjust agitation / aeration in the following order to maintain oxygen levels at D.O. ≥ 40%: increase tank pressure to 11 psi; increase agitation paddle rim speed to 175 cm / sec; increase aeration rate to 0.5 VVM. Add Dow 1520-US as needed to control foam. (About 0.1ml / L defoamer should be added before sterilization to help prevent foaming).

[0089] Within 12 hours after the pH rose above 6.0, the inoculum was transferred from the seed ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com