Method for preparing metallic hollow microsphere powder

The technology of hollow microsphere powder and hollow microsphere is applied in the field of material processing, which can solve the problems of difficult control and complicated preparation process, and achieve the effects of simple process, few processing steps, and simple structure phase composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

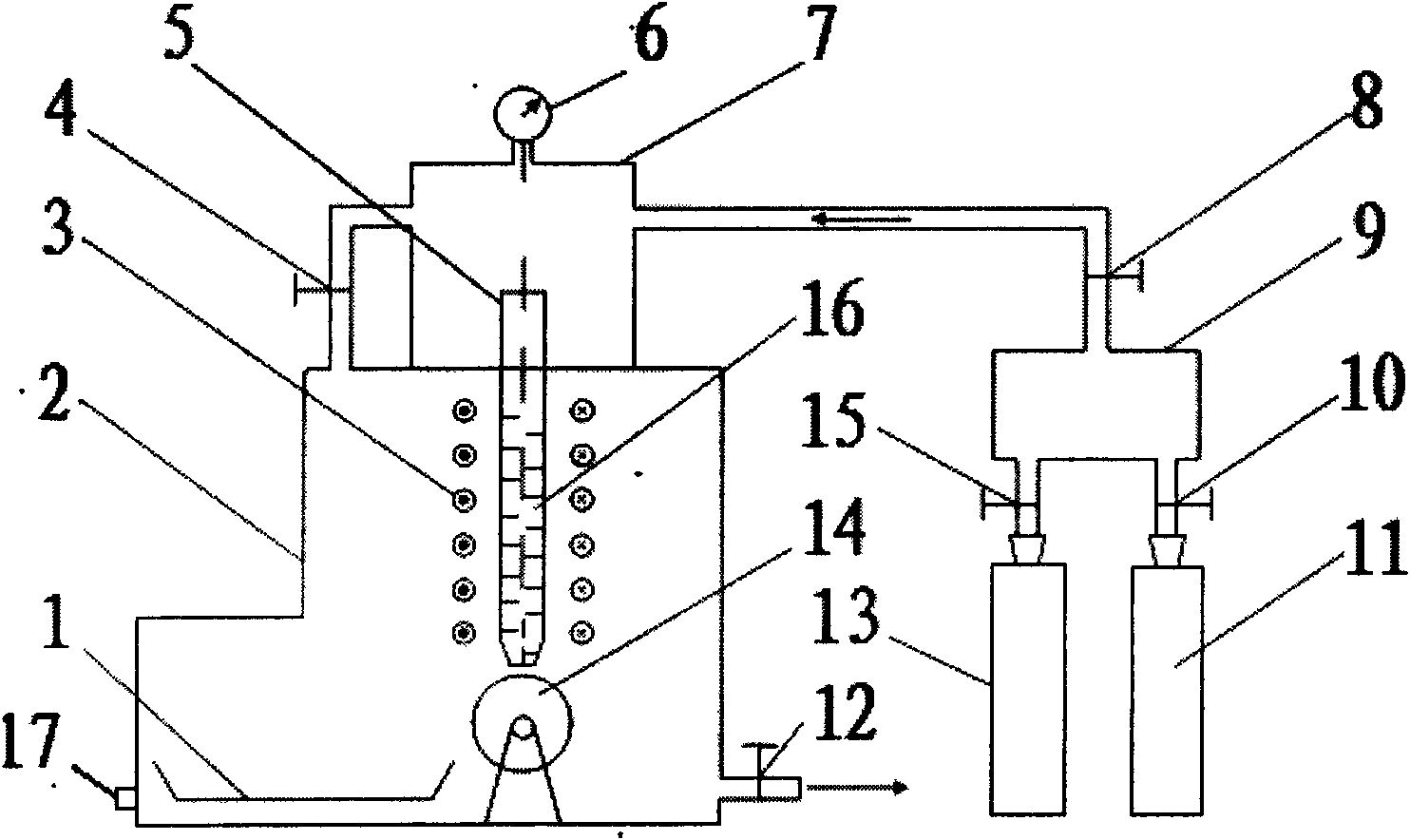

[0018] The preparation method of metal hollow microspheres of the present invention is to utilize the above-mentioned forming device to implement according to the following steps:

[0019] Step 1, put the high-purity metal weighed according to the ratio of the master alloy into the crucible 5, open the communication valve 4, start the vacuum pump 17, and evacuate the large vacuum chamber 2 and the small vacuum chamber 7 to 10 2 ~10 -2 Close vacuum pump 17 after Pa, open argon valve 15 and pressure regulating valve 8, make the argon in the argon tank 13 enter mixing chamber 9, small vacuum chamber 7 and large vacuum chamber 2 successively, then close argon valve 15; After repeated vacuuming-refilling with argon for 3 to 5 times, then close the argon valve 15 and the pressure regulating valve 8 in turn, and then vacuumize again to make the vacuum degree in the large vacuum chamber 2 and the small vacuum chamber 7 reach 10 2 ~10 -2 Pa;

[0020] Step 2, energizing the high-freq...

Embodiment 1

[0026] 92% high-purity Ni (99.99%) and 8% high-purity Pb (99.99%) are used to melt the master alloy. The size of the quartz crucible is Φ16mm×150mm. There is a nozzle of Φ0.8mm at the bottom of the crucible. The ball forming device is implemented according to the following steps:

[0027] Step 1, put the high-purity metal weighed according to the ratio of the master alloy into the crucible 5, open the communication valve 4, start the vacuum pump 17, and evacuate the large vacuum chamber 2 and the small vacuum chamber 7 to 10 2 Close vacuum pump 17 after Pa, open argon valve 15 and pressure regulating valve 8, make the argon in the argon tank 13 enter mixing chamber 9, small vacuum chamber 7 and large vacuum chamber 2 successively, then close argon valve 15; After repeated vacuuming-refilling with argon for 3 to 5 times, then close the argon valve 15 and the pressure regulating valve 8 in turn, and then vacuumize again to make the vacuum degree in the large vacuum chamber 2 a...

Embodiment 2

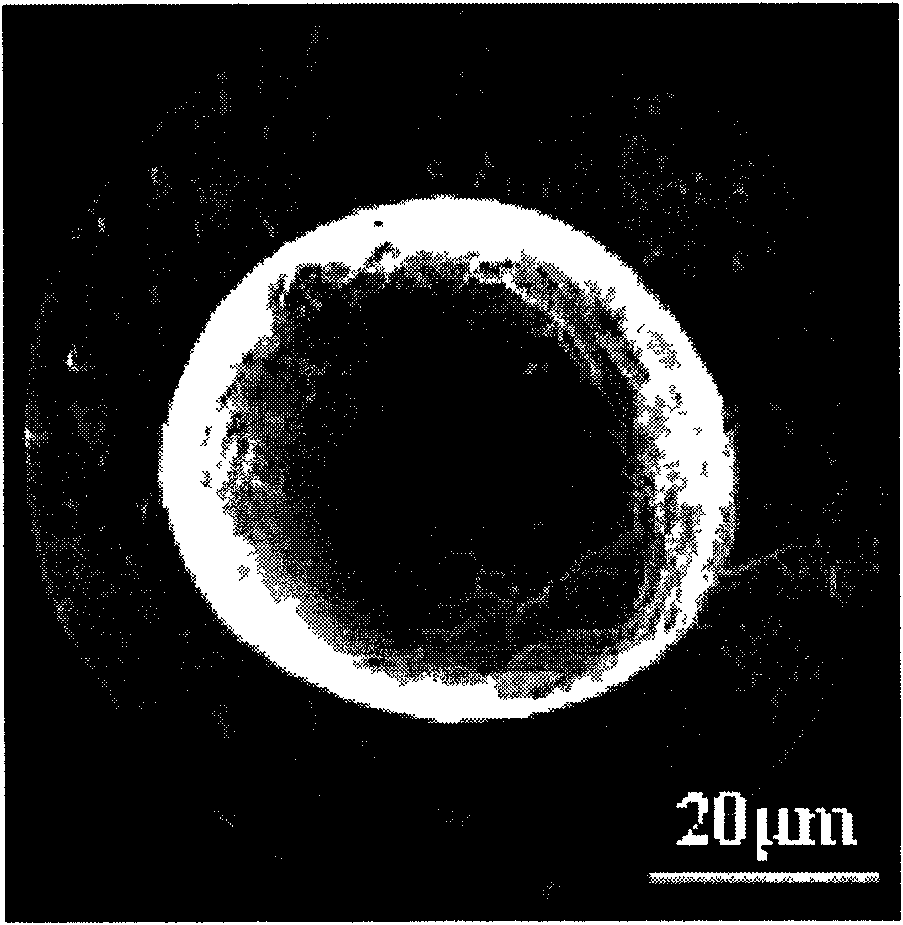

[0032] Embodiment 2: According to the steps of embodiment 1, control the following parameters to implement:

[0033] Select 90% high-purity Cu (99.99%) and 10% high-purity Pb (99.99%) to melt the master alloy, evacuate the large vacuum chamber 2 and the small vacuum chamber to 10Pa, and the air pressure indicated by the barometer 6 reaches 13×10 3 At Pa, the rotational speed of the copper roller 14 is controlled to be 30 m / s. The hollow microspheres produced in Example 2 have a rounded shape, a pore diameter of about 40 microns, and a ratio of inner and outer diameters of about 0.66. The spherical shell is closed without mesopores, and the solidified structure of the spherical shell is fine and uniform and has the characteristics of rapid solidification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com