Iron (III)-carbohydrate based phosphate adsorbent

A phosphate adsorbent, carbohydrate technology, applied in the direction of iron compounds, iron organic compounds, iron group organic compounds without C-metal bonds, etc., can solve the problems of low adsorption capacity of phosphate adsorbents and low patient compliance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

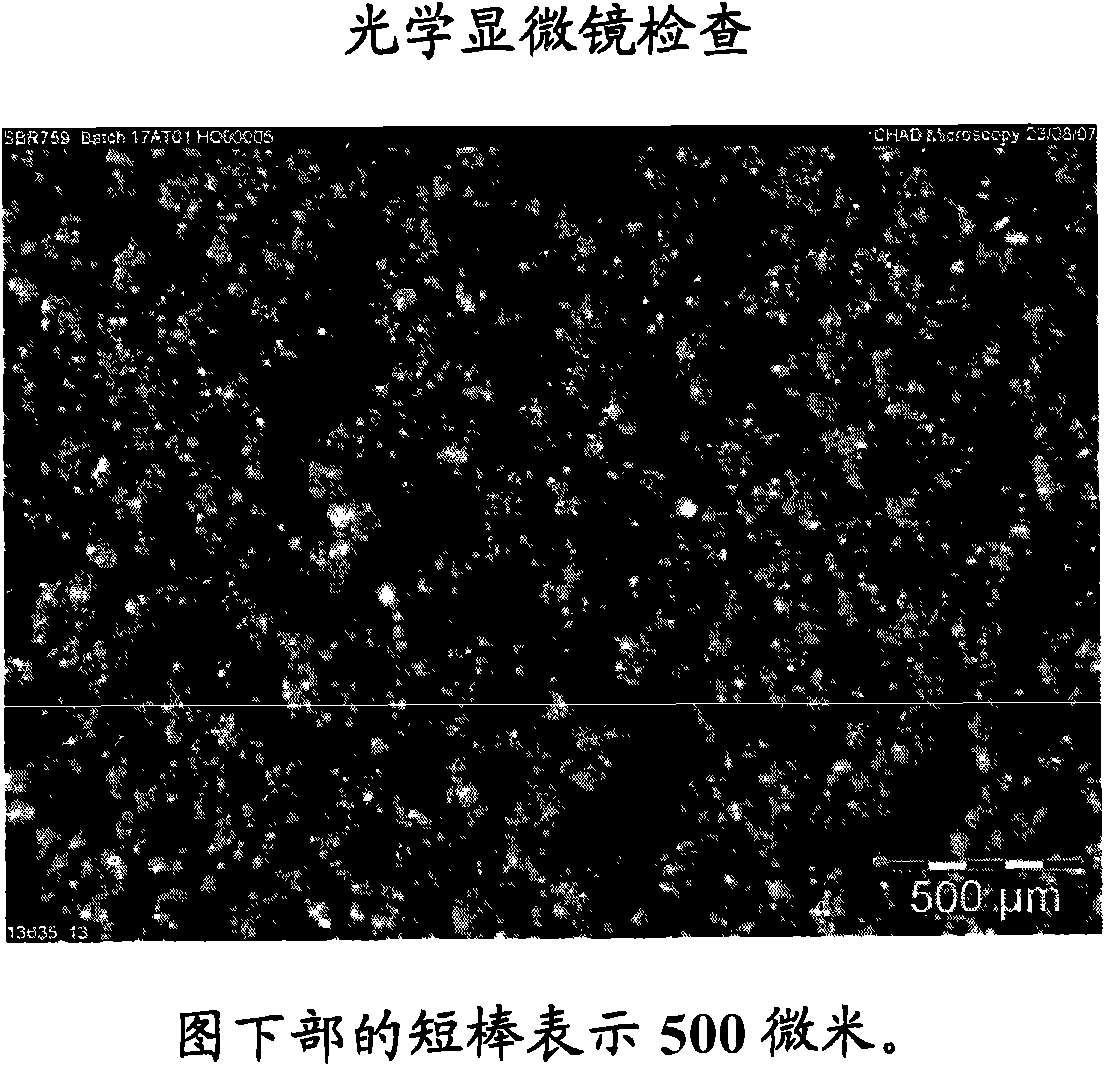

[0046] The preparation method of gamma-iron (III)

[0047] It was not expected that gamma-iron(III) oxyhydroxides could be obtained selectively directly from iron(III) sources such as iron(III chloride) without the use of iron(II) and subsequent oxidation steps, and gamma-iron(III) A mixture of iron(III) oxyhydroxides and ferrihydrite.

[0048] The present invention also includes a novel process for the preparation of gamma-iron(III) oxyhydroxides comprising the steps of: bringing an aqueous solution of an iron(III) salt with an aqueous base solution between pH 6-10, optionally in the presence of starch reaction. Starch can be added after the reaction of step a), that is, after the iron salt and alkali are completely mixed.

[0049] If not present in step a), starch can be added in another step (step b), for example after the iron salt and alkali have been thoroughly mixed. In another embodiment, starch is added in step a) and more starch is added in step b).

[0050] In...

Embodiment 1

[0239] Example 1 : Preparation of Iron(III)-Based Phosphate Adsorbents

[0240] To a mixture of 41 kg potato starch, 118 kg sodium carbonate and 480 kg water was added a solution of 148 kg iron(III) chloride hexahydrate in 588 kg water within 30 minutes at a temperature of 20-35°C. The resulting brown suspension was stirred at 25°C for at least 60 minutes, then filtered and washed 3 times with 968 kg of water, each time using a decanter centrifuge. Then 160 kg of water, 41 kg of sucrose and 129 kg of ethanol were added and the mixture was stirred for at least 60 minutes. 172 kg of a russet powdery final product was isolated by spray drying using NIRO SD42 under appropriate spray drying parameters or at an atomization pressure of 1.2 bar, an output temperature of 65° C. and an input temperature of 140° C.

[0241] The product can be filled directly into sachets or stick packs without any other treatment.

Embodiment 2

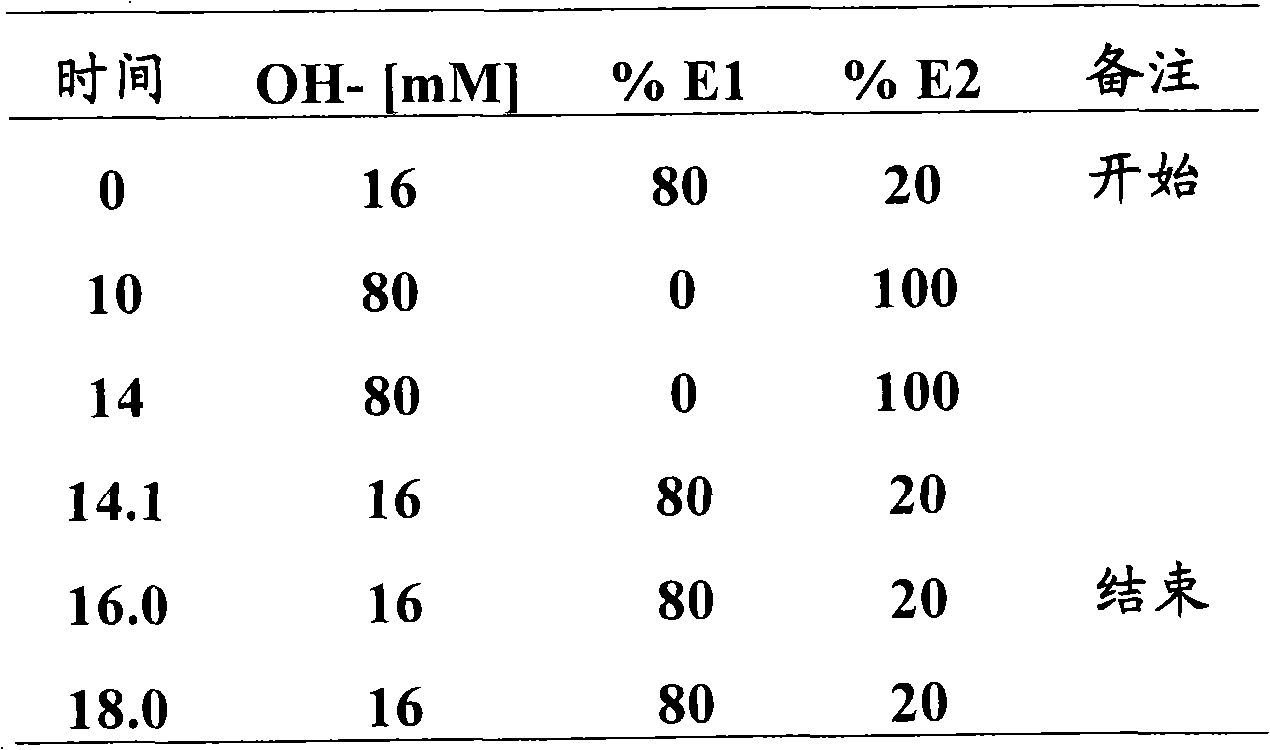

[0242] Example 2 : Preparation of Iron(III)-Based Phosphate Adsorbents

[0243] A solution of 21.1 g of sodium carbonate in 105 g of water (solution A) and a solution of 26.5 g of iron(III) chloride hexahydrate in 55 g of water (solution B) were prepared. Add solutions A (4.2 g / min) and B (2.7 g / min) to a solution of 7.36 g of potato starch in 40 g of water over 30 minutes: Mix solutions A and B continuously and then add to the potato starch suspension . The resulting russet suspension was stirred at 25° C. for at least 1 hour, filtered and washed 3 times with 173.6 g of water each time. To the obtained russet solid were added 14.6 g of water, 7.36 g of sucrose and 24.2 g of ethanol, and the mixture was stirred for 60 minutes. Fluidized spray drying with appropriate FSD conditions yielded 18.4 g of the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com