Coarse fraction ilmenite titanium selecting art

A technology of ilmenite and coarse-grained grade, which is applied in the field of coarse-grained ilmenite titanium separation process, and can solve the problems of low titanium recovery rate, serious water consumption, and small floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

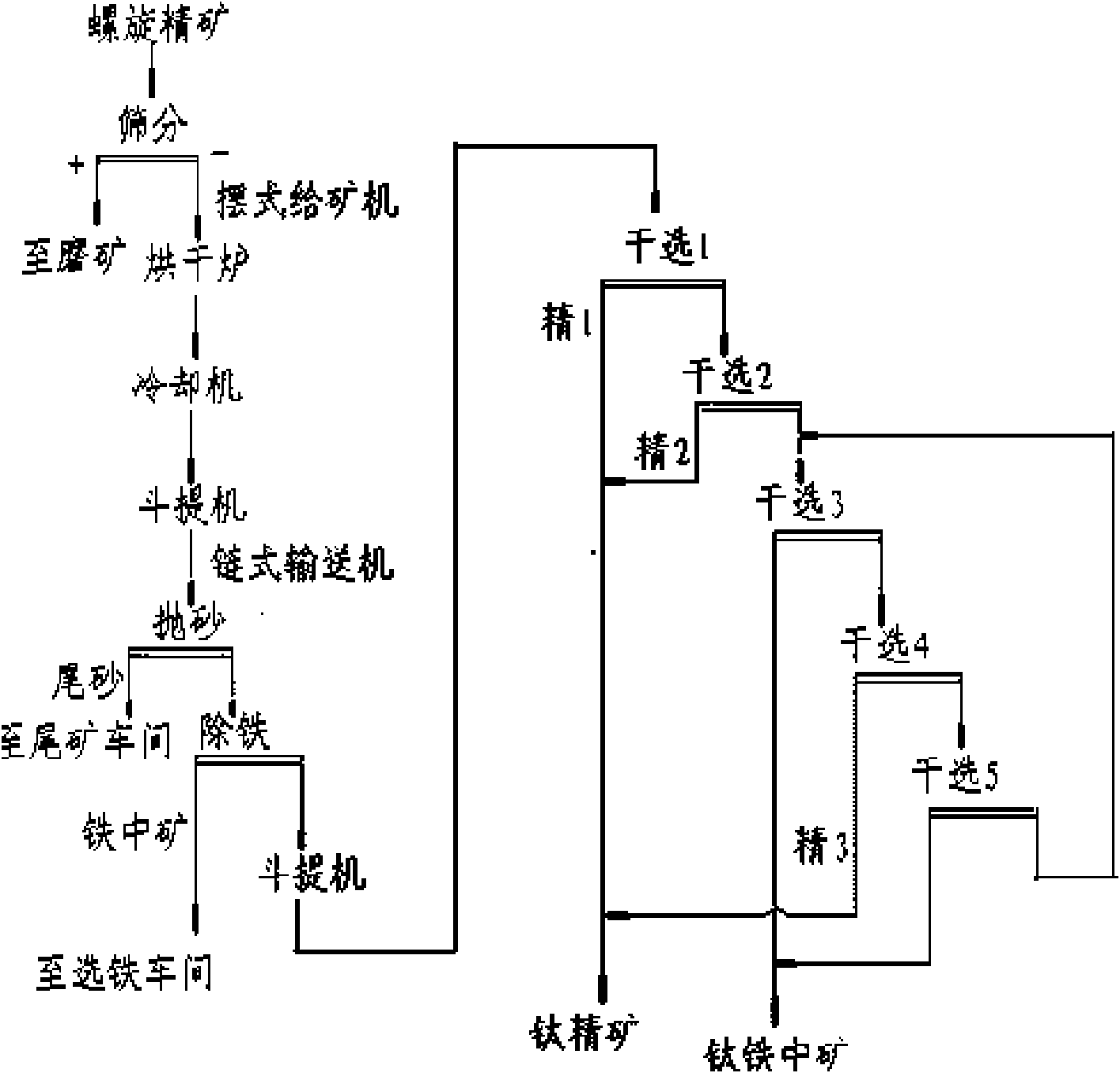

[0030] TiO obtained by spiral treatment 2 100 tons of spiral concentrate with a content of 37%, 90 tons of the part with a particle size of 0.6-0.074mm is collected through a double-layer high-frequency vibrating screen, dried by a dryer, cooled by a cooler, and then enters the sand blasting drum and iron removal drum, producing 77 tons of TiO 2 Titanium medium ore with a content of 43.5%, after 5 times of dry separation, produces 70 tons of TiO 2 The qualified titanium concentrate with a content of 47% has a titanium recovery rate of 88.92%.

Embodiment 2

[0032] TiO obtained by spiral treatment 2 100 tons of spiral concentrate with a content of 36%, 88 tons of the part with a particle size of 0.6-0.074mm is collected through a double-layer high-frequency vibrating screen, dried by a dryer, cooled by a cooler, and then sent to a sand blasting drum and iron removal drum, producing 75 tons of TiO 2 Titanium medium ore with a content of 43.3%, after 5 times of dry separation, produces 67 tons of TiO 2 The qualified titanium concentrate with a content of 47% has a titanium recovery rate of 87.47%.

Embodiment 3

[0034] TiO obtained by spiral treatment 2 100 tons of spiral concentrate with a content of 35%, 85 tons of the part with a particle size of 0.6-0.074mm is collected through a double-layer high-frequency vibrating screen, dried by a dryer, cooled by a cooler, and then enters the sand blasting drum and iron removal drum, producing 71 tons of TiO 2 Titanium medium ore with a content of 43.2%, after 5 times of dry separation, produces 65 tons of TiO 2The qualified titanium concentrate with a content of 47% has a titanium recovery rate of 87.29%.

[0035] Advantages of the present invention: due to the adoption of double-layer screening, coarse particles and fine particles are separated, greatly improving the sorting quality (TiO 2 Increased by more than 0.3%, concentrate output increased by more than 20%), reduced dust pollution (reduced by more than 70%). The mineral processing cost of the process of the present invention is 130-180 yuan / ton, the mineral processing cost of spi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com