High-temperature endurable active toughener powder used for epoxy resin and preparation method thereof

A technology for active toughening agent and epoxy resin, which is applied in the field of high-temperature-resistant active toughening agent powder for epoxy resin and its preparation, can solve the problems that have not yet been published in literature or patent reports, and achieve low cost and low molecular weight. Easy and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

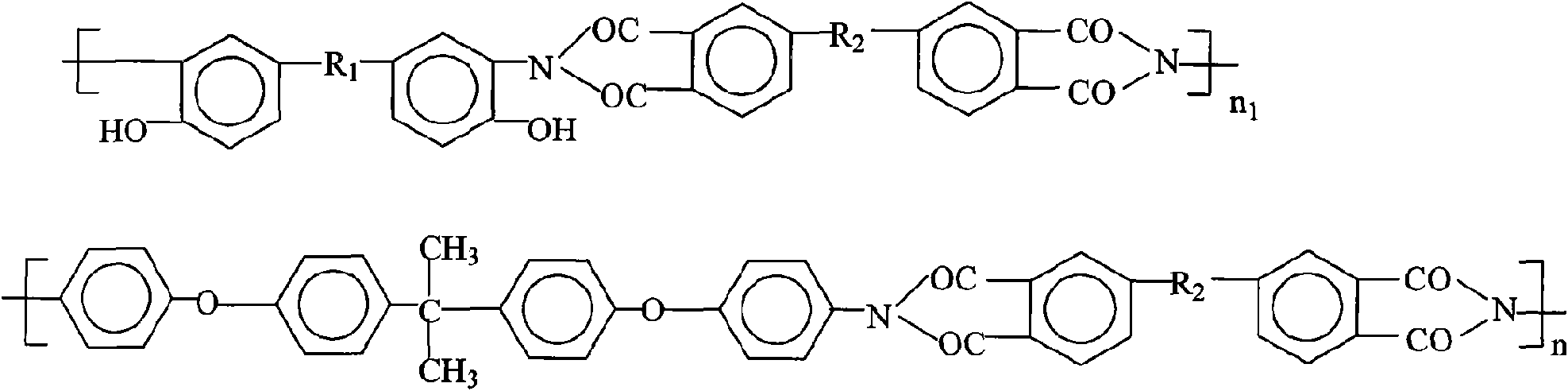

Method used

Image

Examples

Embodiment 1

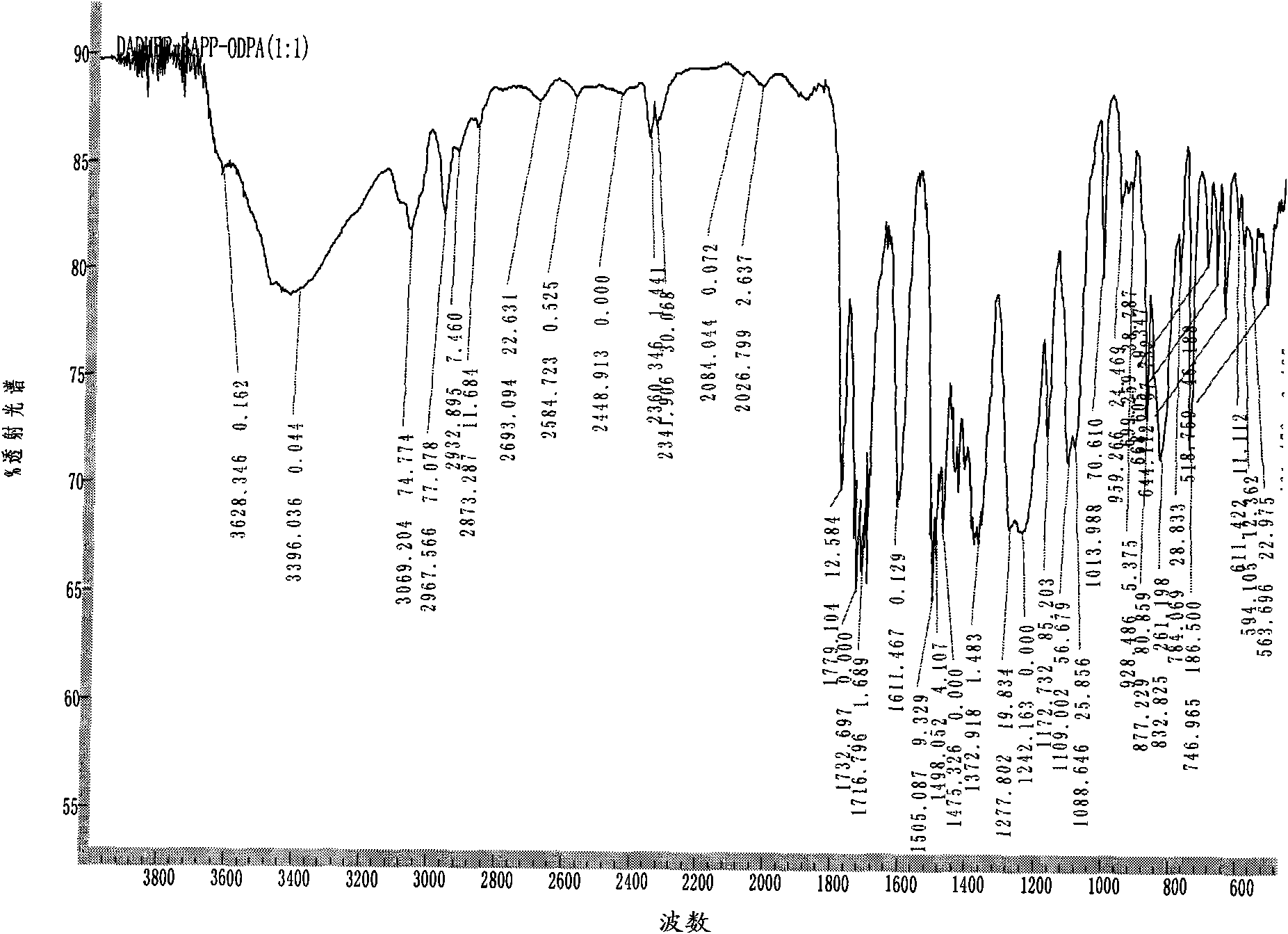

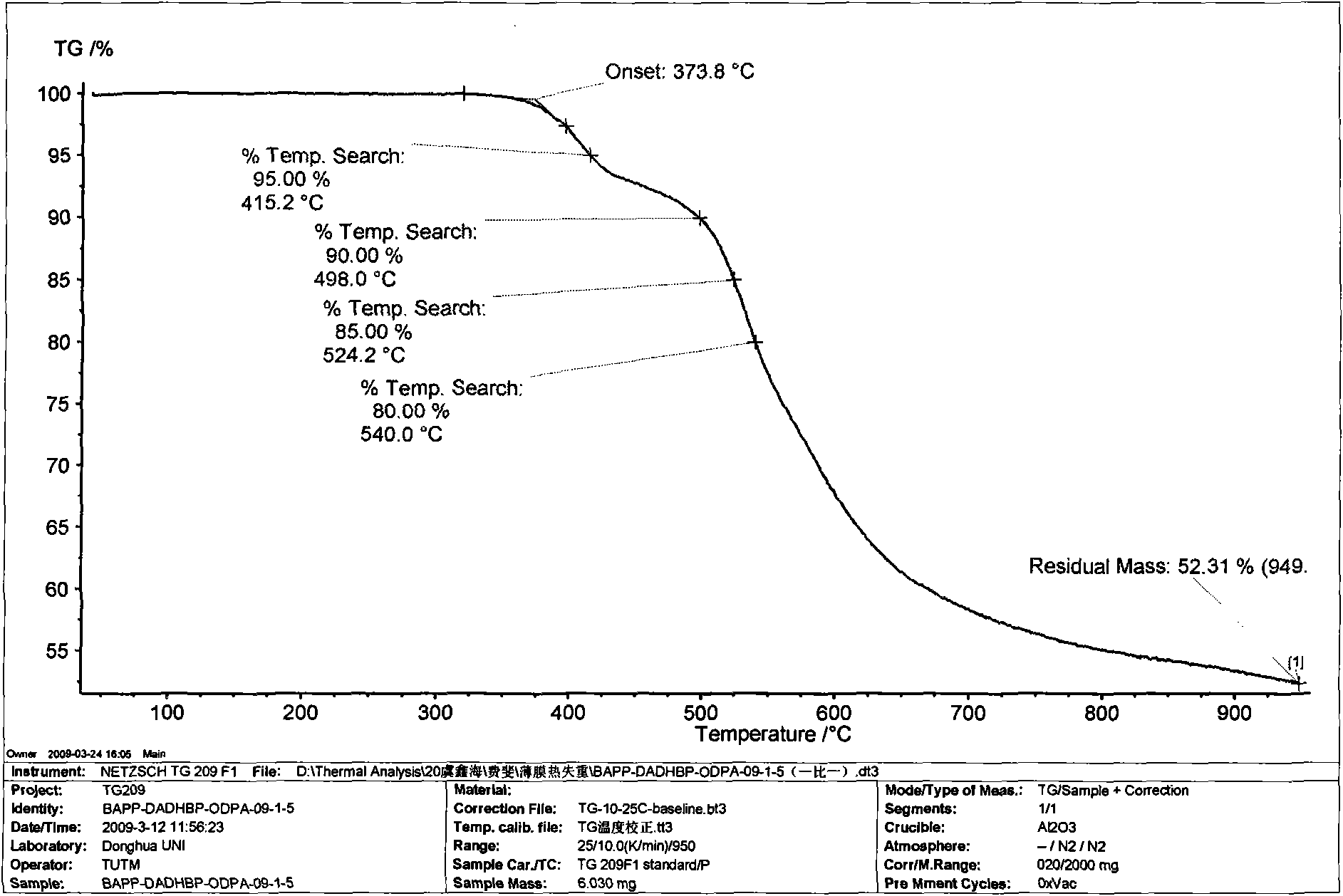

[0056] 21.6 g (0.1 mole) of 3,3'-diamino-4,4'-dihydroxybiphenyl (DADHBP), 41.0 g (0.1 mole) of 2,2-bis[4-(4-aminophenoxy Base) phenyl] propane (BAPP), 62.0 grams (0.2 moles) of 3,3',4,4'-tetracarboxydiphenyl ether dianhydride (ODPA), 0.015 moles of isoquinoline and 1246 grams of o-cresol Put it into the reaction kettle, stir, heat up to the temperature range of 100°C-150°C, and after maintaining the reaction for 5 hours, pour it into 24920 grams of ethanol precipitating agent under high-speed stirring state while it is hot, and precipitate solid powder, filter and use Wash with ethanol for 2-3 times, soak in acetone for 5 hours, filter, wash with deionized water for 2-3 times, and dry to obtain 112.7 grams of 1DADHBP / 1BAPP / 2ODPA-PI white powder, which is a high-temperature-resistant active toughening agent for epoxy resin Powder (theoretical amount 117.4 grams), yield is 96%, and its Fourier transformation infrared spectrum (FTIR) is as figure 2 As shown, the thermogravimetr...

Embodiment 2

[0060] 21.6 g (0.1 mol) of 3,3'-diamino-4,4'-dihydroxybiphenyl (DADHBP), 82.0 g (0.2 mol) of 2,2-bis[4-(4-aminophenoxy Base) phenyl] propane (BAPP), 93.0 grams (0.3 moles) of 3,3',4,4'-tetracarboxydiphenyl ether dianhydride (ODPA), 0.01 moles of isoquinoline and 983 grams of o-cresol Put it in the reaction kettle, stir, heat up to the temperature range of 100°C-150°C, and after maintaining the reaction for 5 hours, pour it into the precipitating agent of 9000 grams of ethanol and 830 grams of isopropanol under high-speed stirring state while it is hot, Precipitate solid powder, filter, wash with ethanol 2-3 times, soak in acetone for 5 hours, filter, wash with deionized water 2-3 times, dry to obtain 183.9 grams of 1DADHBP / 2BAPP / 3ODPA-PI white powder, namely epoxy resin With high temperature resistant active toughening agent powder (theoretical amount 185.8 grams), yield is 99%, and its Fourier transformation infrared spectrum (FTIR) is as Figure 4 shown.

[0061] The molec...

Embodiment 3

[0064] 21.6 g (0.1 mole) of 3,3'-diamino-4,4'-dihydroxybiphenyl (DADHBP), 123.0 g (0.3 mole) of 2,2-bis[4-(4-aminophenoxy Base) phenyl] propane (BAPP), 124.0 grams (0.4 moles) of 3,3',4,4'-tetracarboxydiphenyl ether dianhydride (ODPA), 0.005 moles of isoquinoline, 0.002 moles of pyridine and 2148 grams Put o-cresol into the reaction kettle, stir, heat up to the temperature range of 100°C-150°C, and after maintaining the reaction for 5 hours, pour it into the precipitate of 20,000 grams of ethanol and 10,000 grams of isopropanol under high-speed stirring state while it is hot. In the analysis agent, a solid powder was precipitated, filtered, washed 2-3 times with ethanol, soaked in acetone for 5 hours, filtered, washed 2-3 times with deionized water, and dried to obtain 238.9 grams of 1DADHBP / 3BAPP / 4ODPA-PI white powder, Promptly epoxy resin is used high temperature resistant active toughening agent powder (theoretical amount 254.2 grams), and yield is 94%, and its Fourier tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com