Ascalloy and manufacturing method thereof

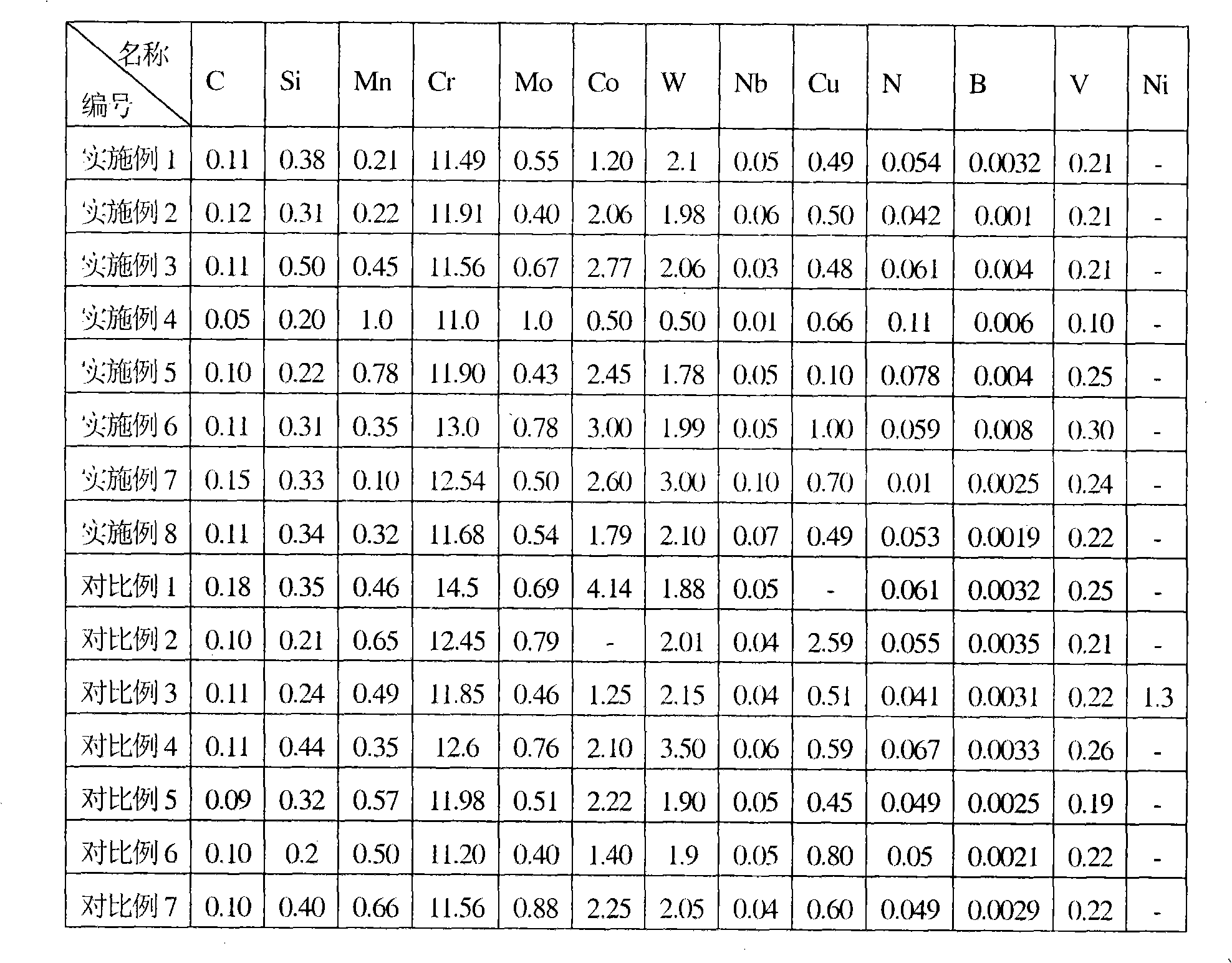

A manufacturing method and technology of heat-resistant steel, applied in the field of steel manufacturing, can solve the problems of high-temperature oxidation resistance, high-temperature creep resistance and high-temperature lasting strength of ferritic heat-resistant steel, low performance of ferritic heat-resistant steel, and low price. expensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

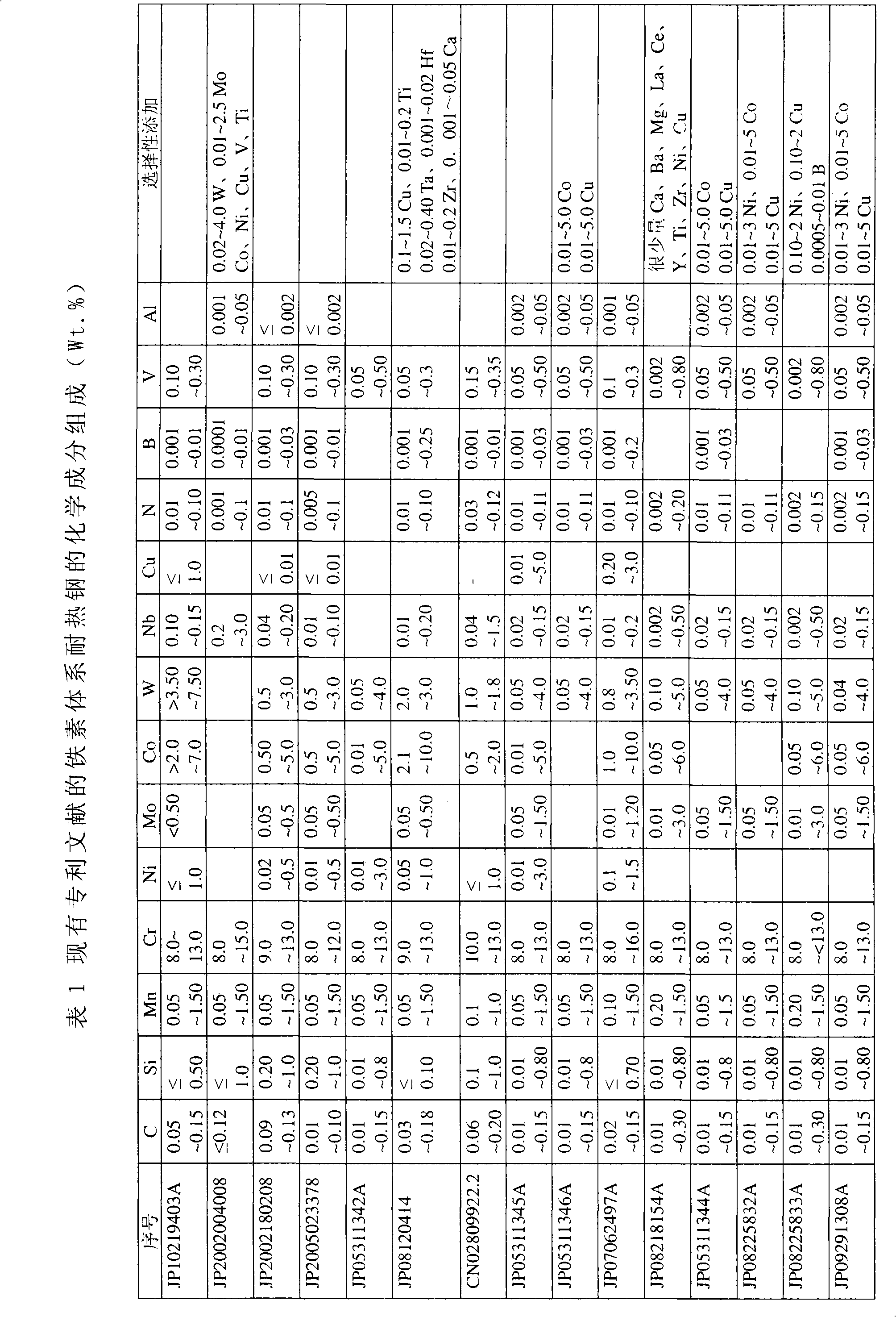

[0048] Table 2 shows the chemical compositions of the steels of the various embodiments of the present invention and comparative examples.

[0049] Smelted under vacuum to obtain 50Kg laboratory molten steel with the following mass percentage chemical composition: C0.11; Si 0.38; Mn 0.21; Cr 11.49; Mo 0.55; Co 1.2; W 2.1; 0.0032; V 0.21, the balance is Fe and unavoidable impurities, and the chemical composition of steel satisfies the relational formula Cr+2Mo+W-40C-30N-Co-0.5Cu=7.225. It is then cast into ingots.

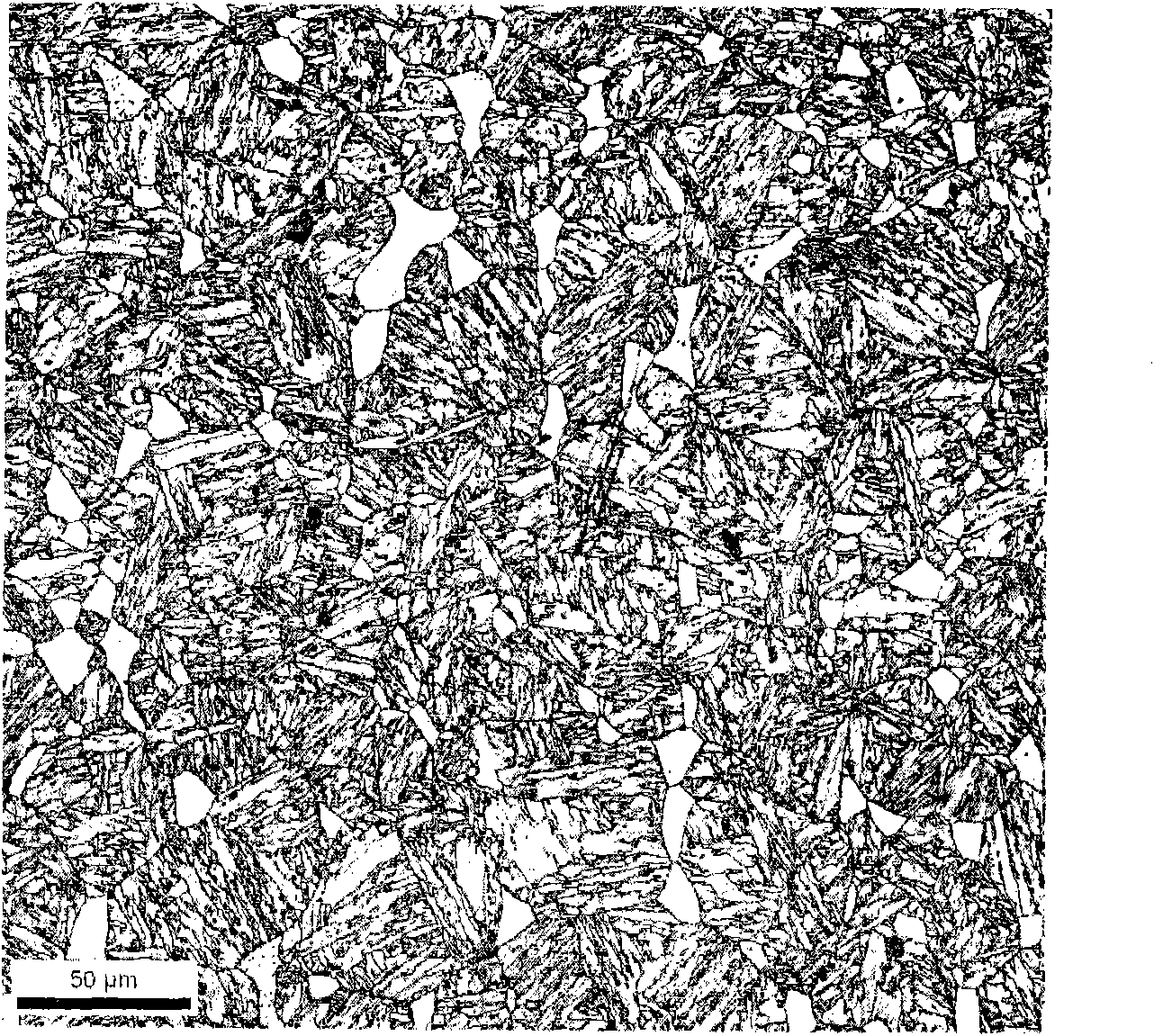

[0050] The steel ingot obtained above was heated to 1190°C, forged into a steel plate with a thickness of 50mm, air-cooled, then heated to 1200°C, rolled into a steel plate with a thickness of 15mm, and the total elongation was 3.3. Obtain required metallographic samples in the longitudinal direction of the obtained steel plate and carry out metallographic erosion, and then detect under an optical microscope to measure the delta ferrite content and the average equi...

Embodiment 2

[0054] The mass percentages of the chemical components in the steel of this example are: C 0.12; Si 0.31; Mn 0.22; Cr 11.91; Mo 0.4; Co 2.06; W 1.98; The balance is Fe and unavoidable impurities.

[0055] The chemical composition of the steel satisfies the relational formula Cr+2Mo+W-40C-30N-Co-0.5Cu=6.32.

[0056] The δ ferrite content in the steel is 2.0%, and the average equivalent diameter of δ ferrite grains is 10 μm.

[0057] The durable life of the steel in this example reaches 1687 hours at 650°C 140Mpa, 11065 hours at 650°C 100Mpa, and 77J / cm impact toughness after aging at 650°C for 10,000 hours 2 .

[0058] Other operations are the same as in Example 1.

Embodiment 3

[0060] The mass percent content of each chemical component in this example is: C 0.11; Si 0.5; Mn 0.45; Cr 11.56; Mo 0.67; Co 2.77; W 2.06; The amount is Fe and unavoidable impurities.

[0061] The chemical composition of the steel satisfies the relational formula Cr+2Mo+W-40C-30N-Co-0.5Cu=5.72.

[0062] The delta ferrite content of the steel is 0.0%.

[0063] The durable life of the steel in this example reaches 1698 hours at 650°C 140Mpa, the durable life at 650°C 100Mpa reaches 10952 hours, and the impact toughness after aging at 650°C for 10,000 hours reaches 74J / cm 2 .

[0064] Other operations are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact toughness | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com