Pixel structure for thin film transistor liquid crystal display and manufacturing method thereof

A technology of liquid crystal display and thin film transistor, which is applied in the pixel structure of thin film transistor liquid crystal display and its manufacturing field, can solve the problems of affecting the display quality of the picture and large jump voltage, etc., so as to improve the display quality of the picture, reduce the jump voltage, improve The effect of screen display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

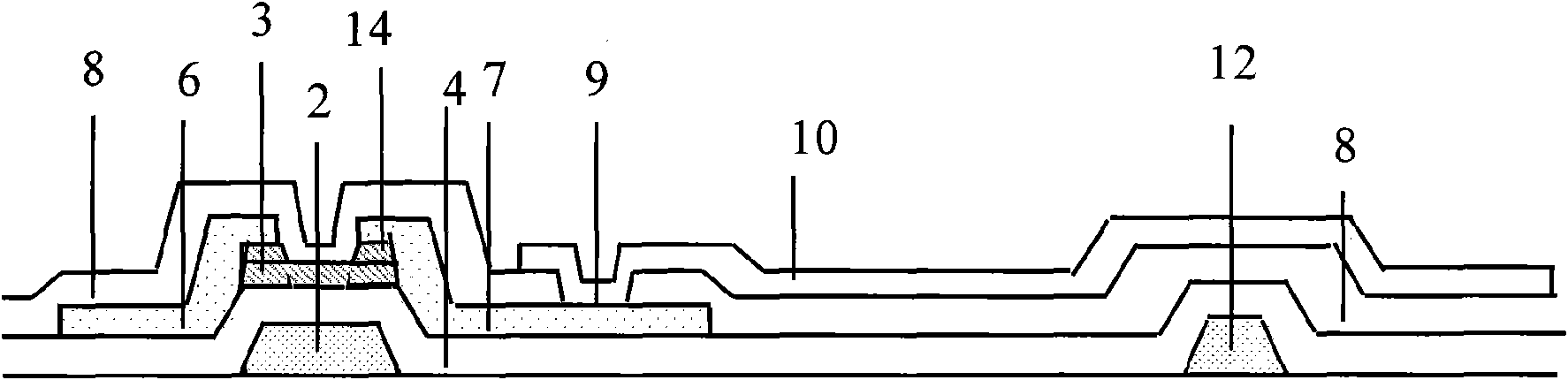

[0062] The basic idea of the present invention is to form the data scanning line, source electrode, drain electrode and pixel electrode in one exposure process, and form the semiconductor layer and ohmic contact layer in one etching process, while simplifying the process, increasing the large storage capacitor.

[0063] Further, when the source electrode and the drain electrode are respectively connected to the ohmic contact layer, a semiconductor doping process can be used for the ohmic contact layer between the source electrode and the drain electrode, so that the ohmic contact layers are not connected to each other, so as to ensure this Invention said pixel structure works normally.

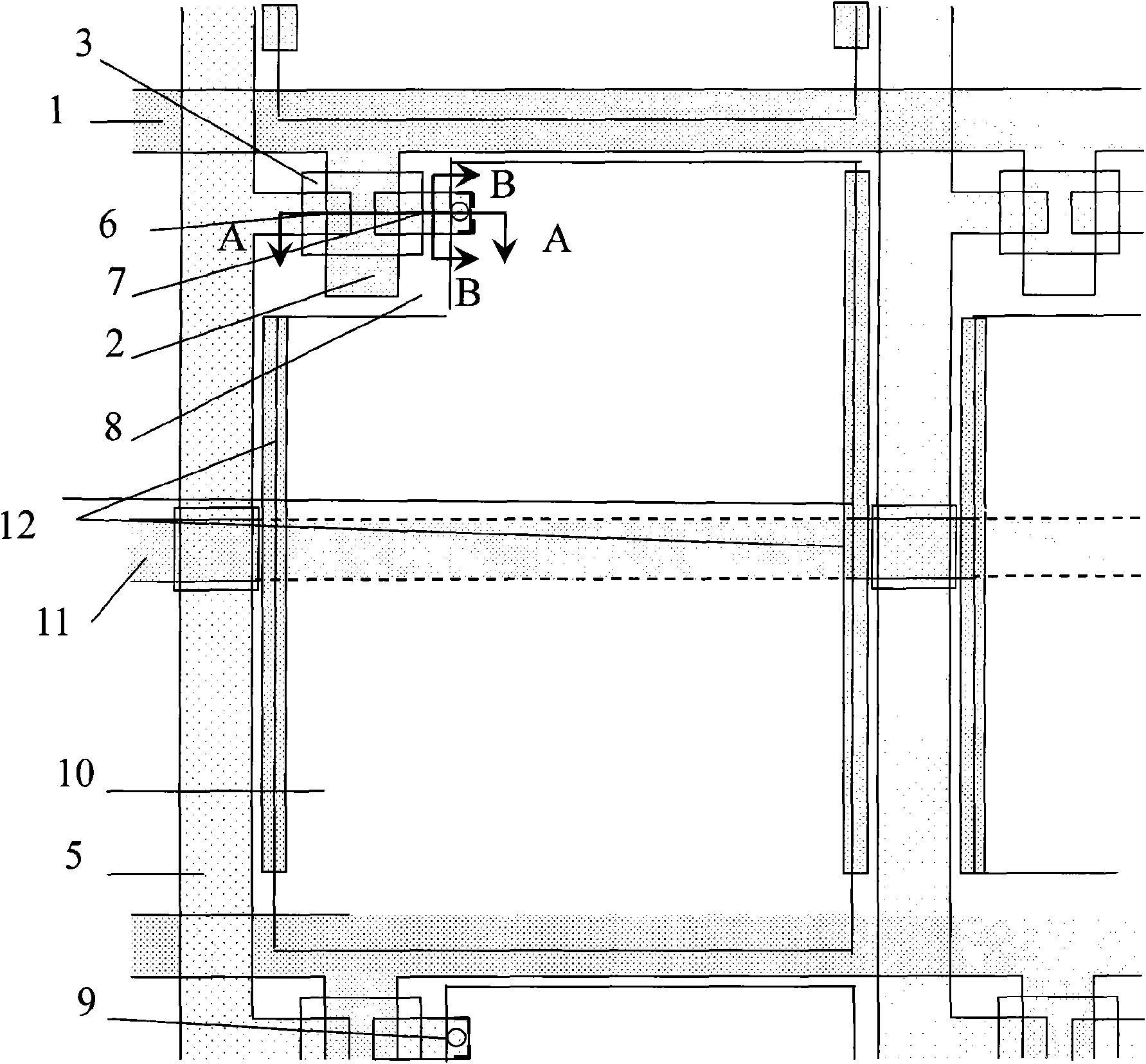

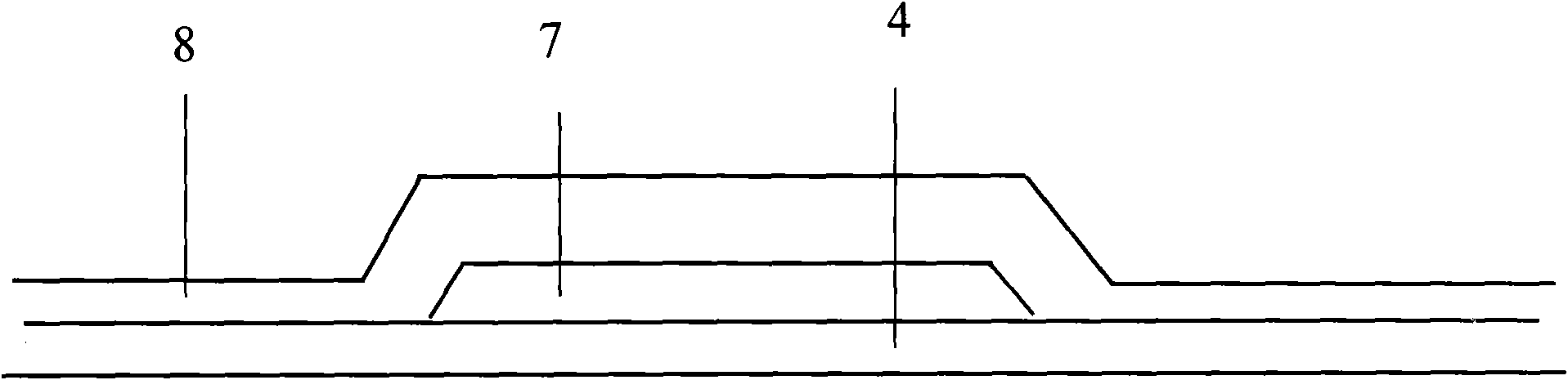

[0064] Hereinafter, the implementation of the pixel structure and manufacturing method of the thin film transistor liquid crystal display of the present invention will be described in detail through specific embodiments in conjunction with the accompanying drawings.

[0065] image 3 It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com