Method for preparing cobalt ferrite magnetic thick film

A cobalt ferrite, thick film technology, applied in the application of magnetic film to substrate, magnetic materials, magnetic objects, etc., to achieve the effects of easy control of components, simple equipment, and good magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

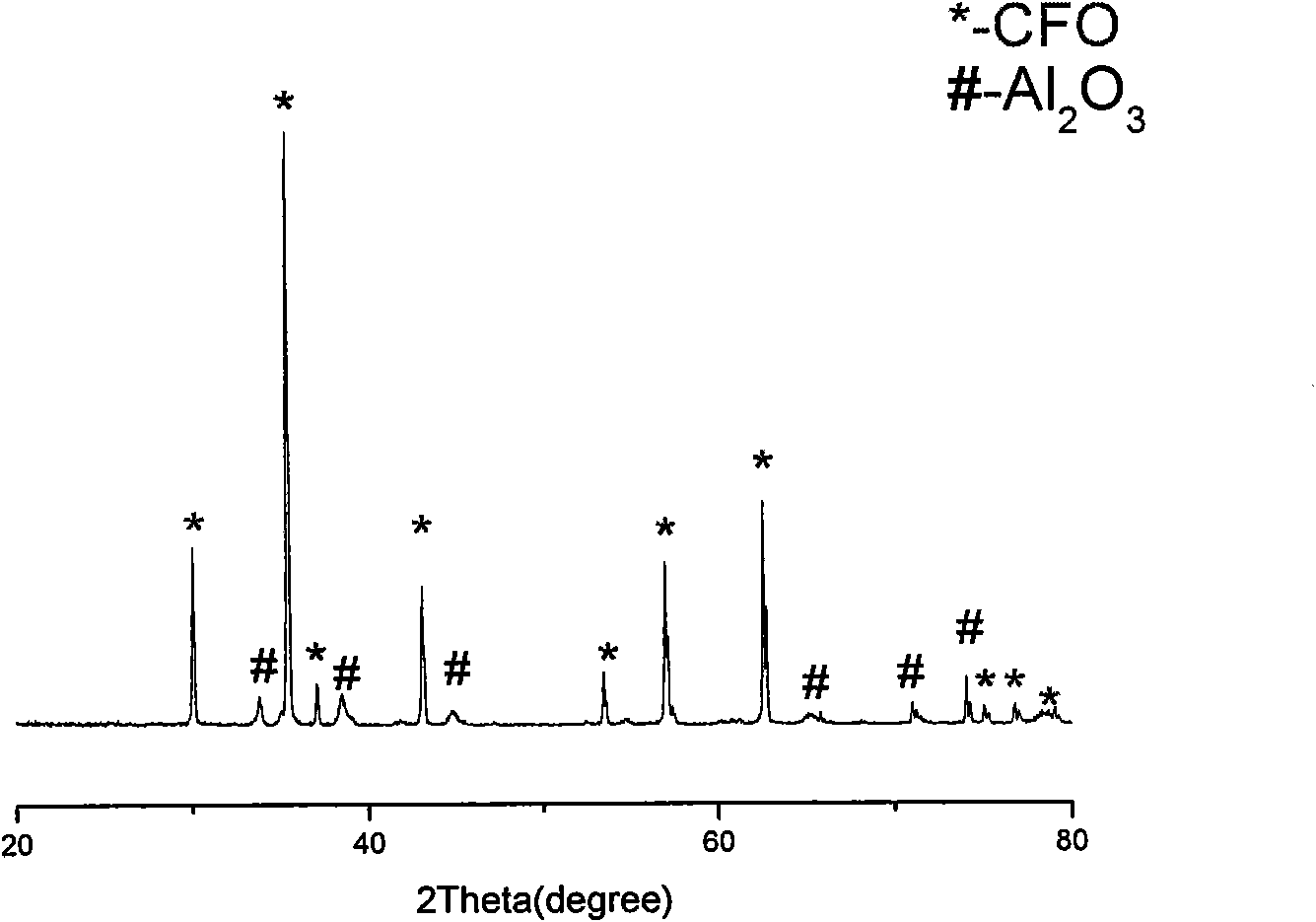

[0026] Electrophoretic composite deposition of magnetoelectric thick films of CFO on platinum (Pt) substrates:

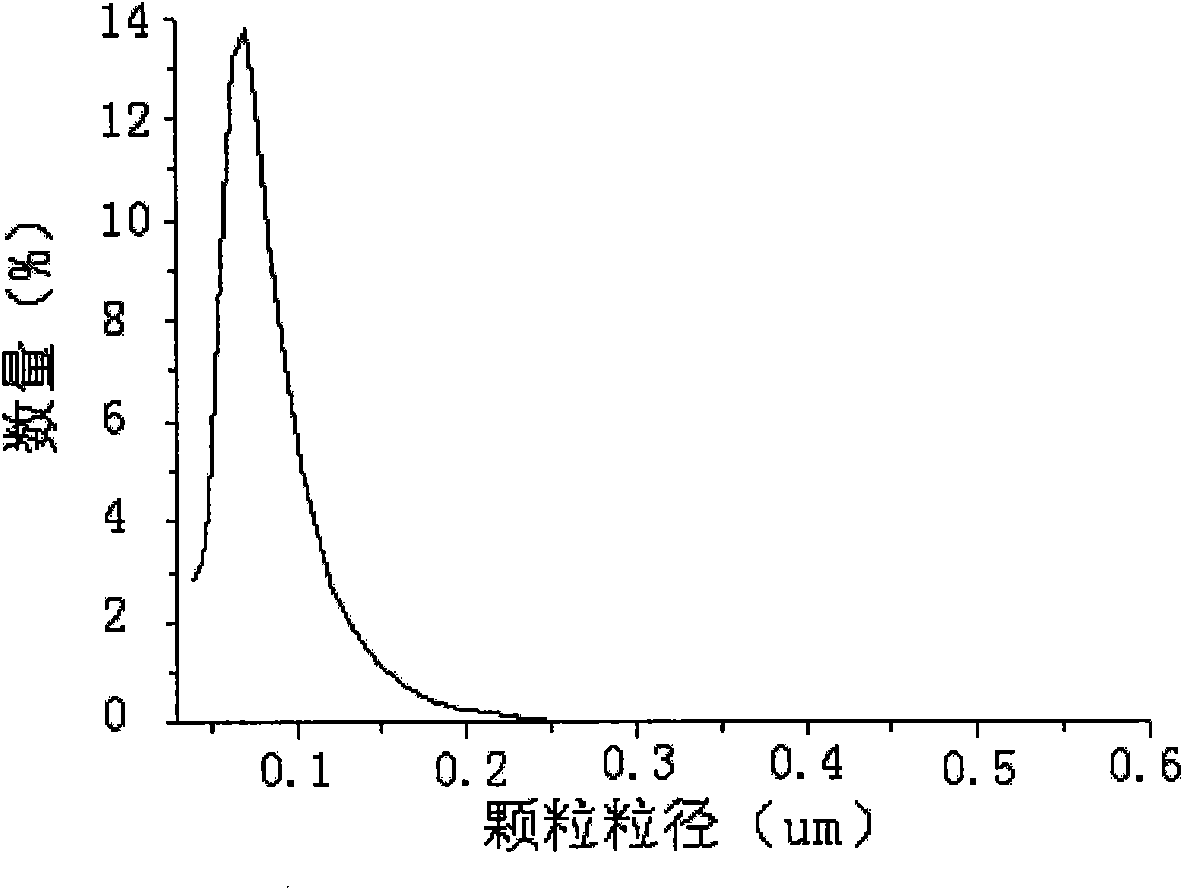

[0027] A. The chemical raw material used is cobalt ferrite nanopowder, and the solvent is n-butanol. Weigh 0.3g of cobalt ferrite powder respectively, then stir the powder in 60mL n-butanol solution for 10 minutes, and then sonicate Disperse for 20 minutes to form a well-mixed suspension (suspension concentration: 5 g / L).

[0028] B. Adjust the used constant current / constant voltage power supply to a constant current state, and maintain a constant output value of 10μA.

[0029] C. Fix the platinum electrode used for electrophoretic deposition in the electrophoresis tank, the distance between the two plates is 2cm, and keep the two plates parallel during the electrophoresis process.

[0030] D. Connect the two electrodes to the power supply, and keep for 15 minutes to obtain a film with a thickness of 5 μm.

[0031] E. Take the thick film obtained by electrophoreti...

Embodiment 2

[0035] Electrophoretic composite deposition of magnetoelectric thick films of CFO on platinum electrodes:

[0036] A. The chemical raw material used is cobalt ferrite powder prepared by hydrothermal treatment, and the solvent is acetylacetone. First weigh 0.6g of cobalt ferrite powder, and then stir the powder in 60mL n-butanol solution for 10 minutes. Then ultrasonically disperse for 20 minutes to form a uniformly mixed suspension (suspension concentration: 10 g / L).

[0037] B. Adjust the used constant current / constant voltage power supply to a constant current state, and maintain a constant output value of 10μA.

[0038] C. Fix the platinum electrode used for electrophoretic deposition in the electrophoresis tank, the distance between the two plates is 2cm, and keep the two plates parallel during the electrophoresis process.

[0039] D. Connect the two electrodes to the power supply and keep for 30 minutes to obtain a thick film with a thickness of 10 μm.

[0040] E. Take ...

Embodiment 3

[0044] Electrophoretic composite deposition of magnetoelectric thick films of CFO on platinum electrodes:

[0045] A. The chemical raw material used is cobalt ferrite powder prepared by hydrothermal treatment, and the solvent is acetylacetone. First weigh 0.6g of cobalt ferrite powder, and then stir the powder in 60mL n-butanol solution for 10 minutes. Then ultrasonically disperse for 20 minutes to form a uniformly mixed suspension (suspension concentration: 10 g / L).

[0046] B. Adjust the used constant current / constant voltage power supply to a constant current state, and maintain a constant output value of 10μA.

[0047] C. The substrate used for electrophoretic deposition is aluminum oxide, and the electrodes coated with high-temperature-resistant materials are fixed in the electrophoresis tank. The distance between the two plates is 2 cm, and the two plates are always kept parallel during the electrophoresis process.

[0048] D. Connect the two electrodes to the power sup...

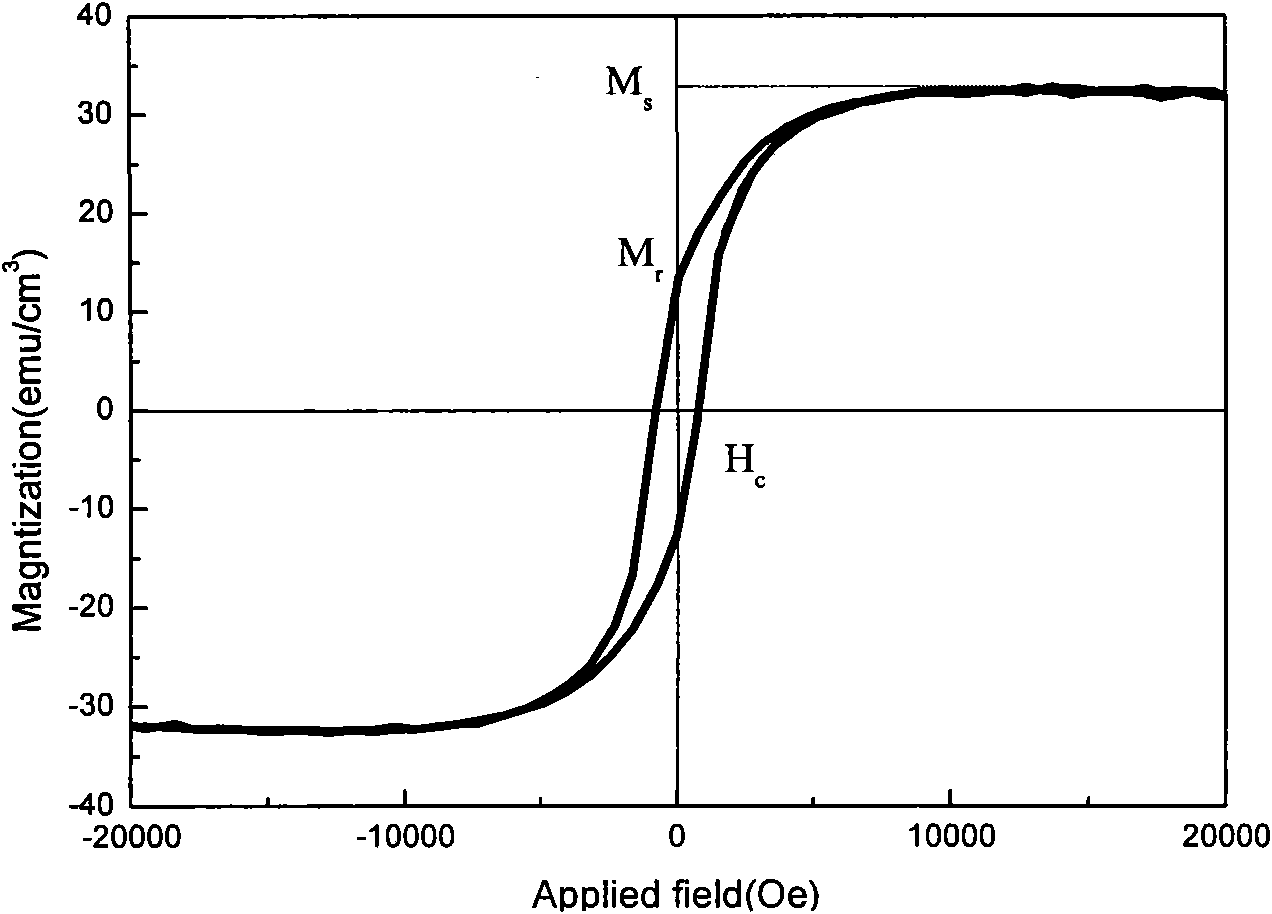

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Residual magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com