Preparation method of polydioxanone copolymer coated magnetic-particles

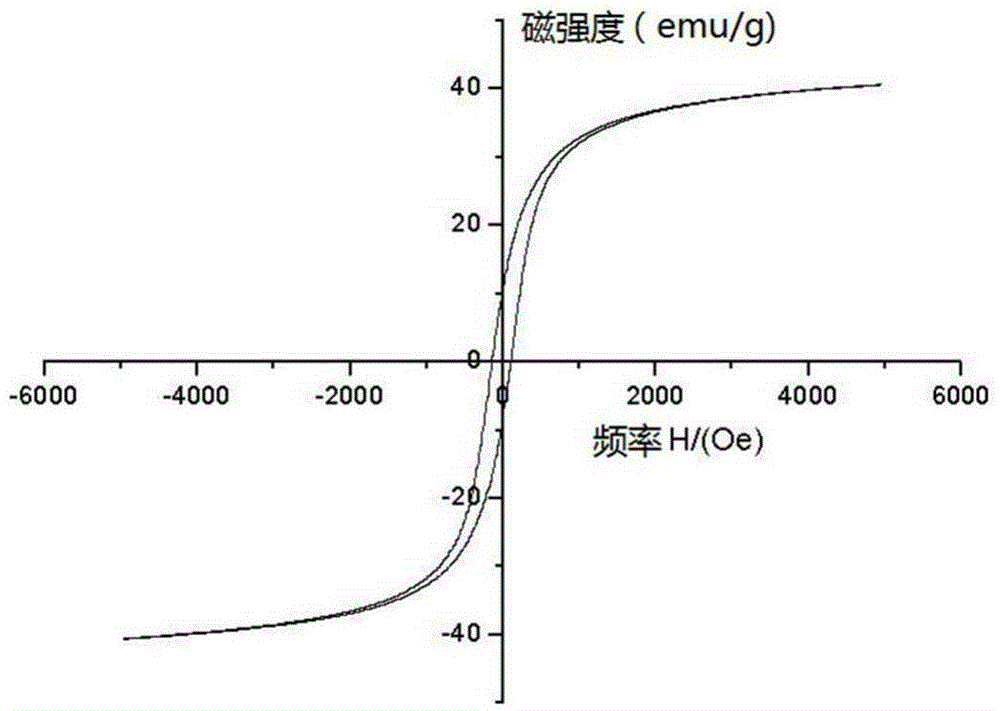

A technology of dioxane copolymer and polydioxanone, which is applied in the directions of non-active ingredient medical preparations, active ingredients-containing medical preparations, pharmaceutical formulas, etc. Hexacyclic ketone has strong crystalline properties, poor solubility and other problems, and achieves the effects of uniform distribution, high saturation magnetic intensity and controllable particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

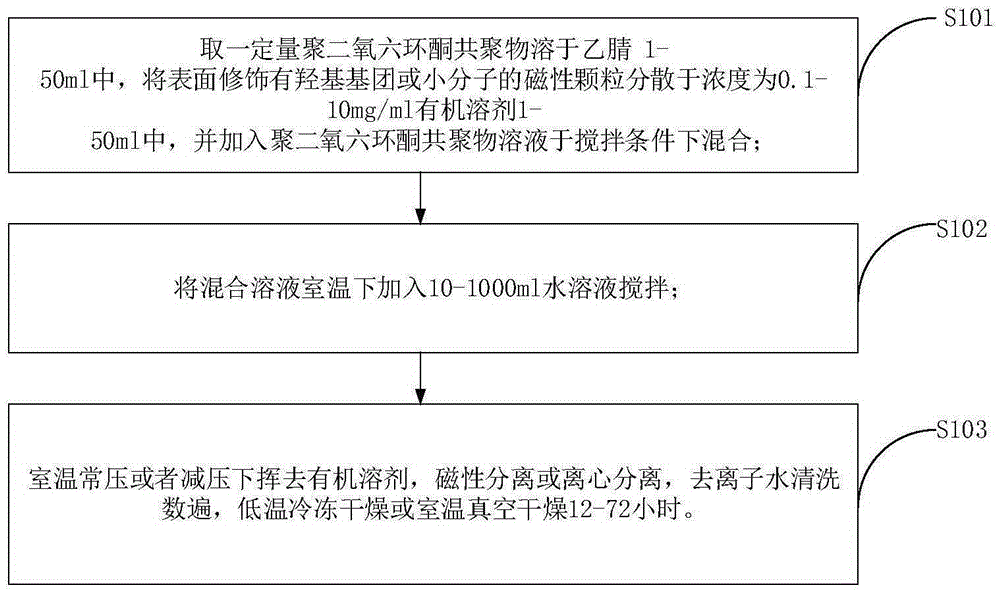

[0028] A method for preparing magnetic particles coated with polydioxanone copolymer, the method for preparing magnetic particles coated with polydioxanone copolymer comprises:

[0029] S101: Dissolve a certain amount of polydioxanone copolymer in 1-50ml of acetonitrile, and disperse magnetic particles with hydroxyl groups or small molecules on the surface in 1-50ml of organic solvent. The concentration of the magnetic particles is 0.1-10mg / ml, and add polydioxanone copolymer solution and mix under stirring condition;

[0030] S102: Add 10-1000ml of aqueous solution (pH7.4 phosphate buffer solution (PBS), 0.1-5% PVA aqueous solution, 1-30% PEG aqueous solution, or 0.1-10% sodium lauryl sulfate to the mixed solution at room temperature, Poloxamer and other emulsifier aqueous solution) stirring;

[0031] S103: Evaporate the organic solvent at room temperature and pressure or under reduced pressure, magnetically separate or centrifuge, wash with deionized water several times, fr...

Embodiment 1

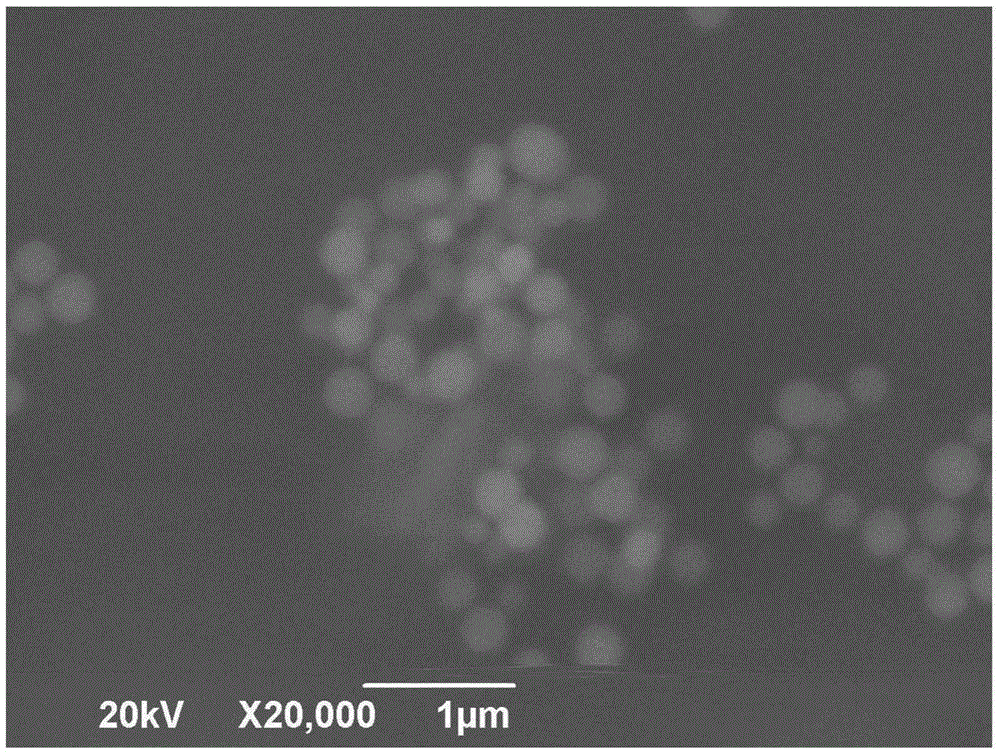

[0042] 1) 0.5 g of mPEG-PDDO (mPEG molecular weight 5k, accounting for molecular weight 75%) was dissolved in 5 ml of acetonitrile, and oleic acid-modified iron ferric oxide nanoparticles (2 mg) were dispersed in 2 ml of n-heptane solution, and the two phases were mixed and stirred .

[0043] 3) Add the mixed solution dropwise into 70ml of PBS buffer solution, and stir at 500 rpm.

[0044] 3) The organic solvent was evaporated under reduced pressure, magnetically separated, and washed several times with deionized water.

[0045] 4) Vacuum drying at room temperature for 48 hours.

Embodiment 2

[0047] 1) Dissolve 1 g of mPEG-PDDO-mPEG (mPEG molecular weight 5k, accounting for 50% of molecular weight) in 4 ml of dimethyl sulfoxide, disperse 2 mg of hydroxyl-modified iron ferric oxide nanoparticles in 2 ml of dimethyl sulfoxide, and mix the two phases Stir.

[0048] 2) Add the mixed solution dropwise into the 10% PEG solution, and stir at 600 rpm.

[0049] 3) The organic solvent was evaporated under reduced pressure, magnetically separated, and washed several times with deionized water.

[0050] 4) Vacuum drying at room temperature for 48 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com