Iron-based amorphous magnetically soft alloy with high saturation flux density and preparation method and application thereof

A magnetic induction strength, iron-based amorphous technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of electronic devices that cannot be widely used, cannot be applied industrially, and have poor high-frequency stability, and achieve excellent soft magnetic properties , unique composition, low coercive force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

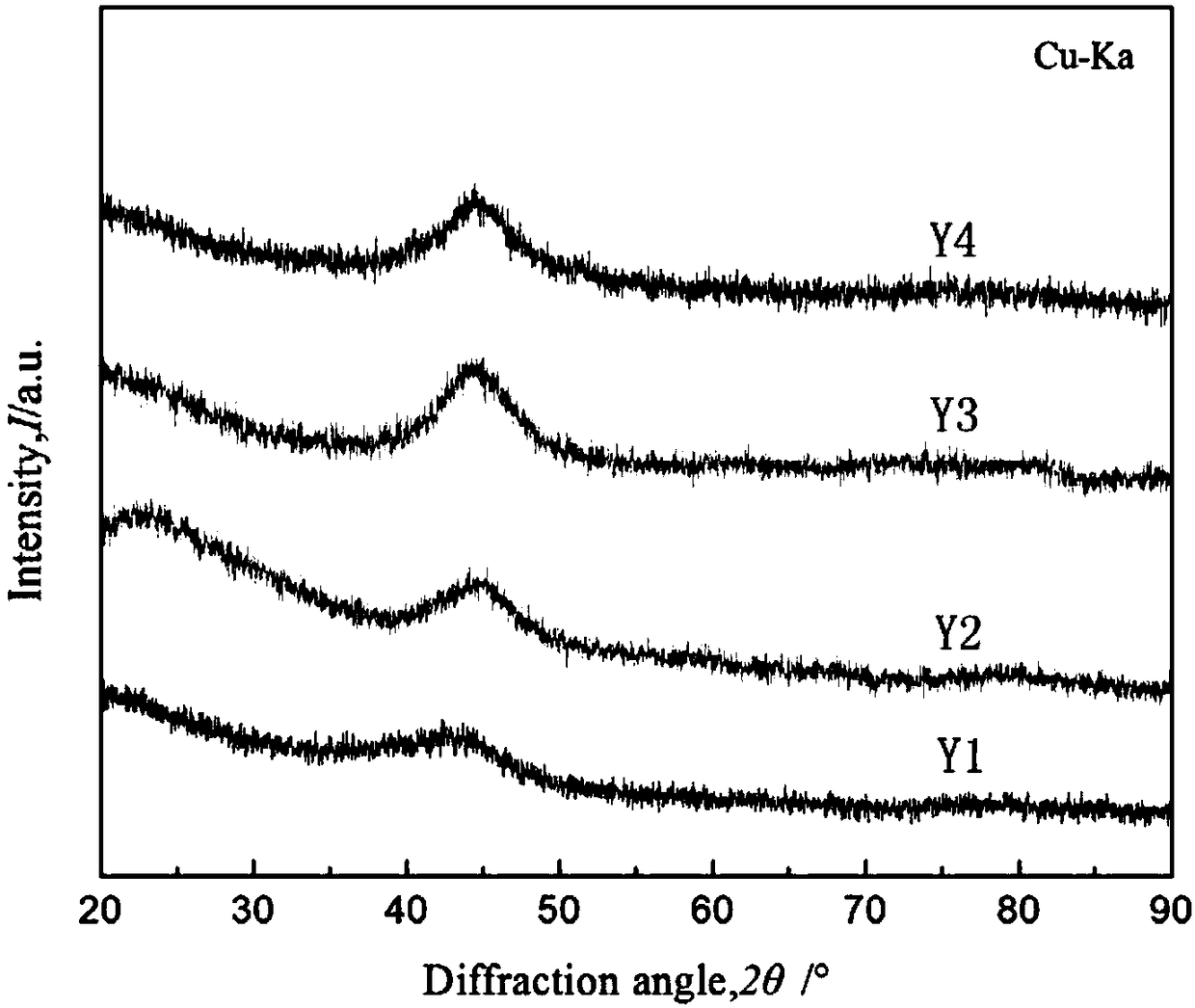

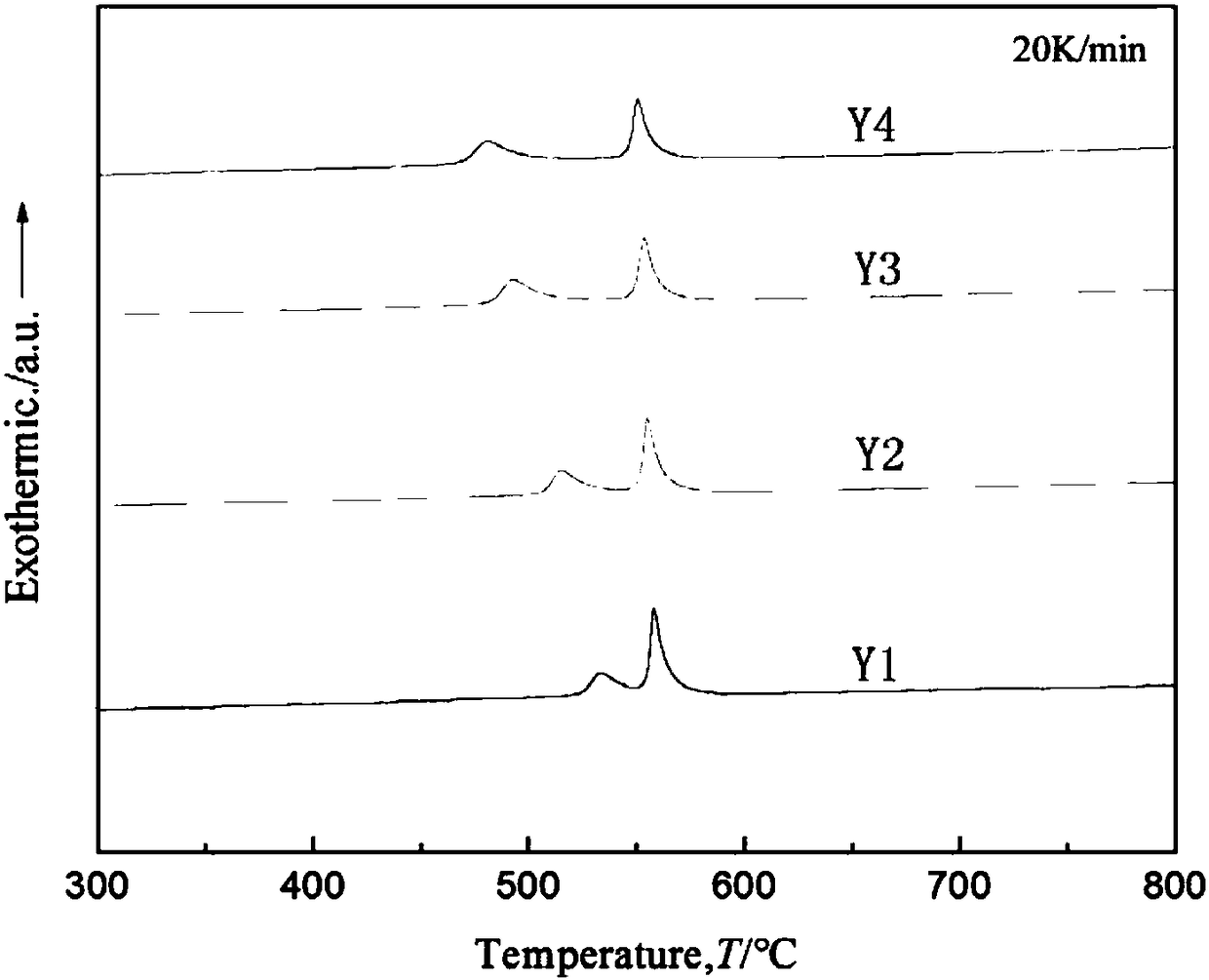

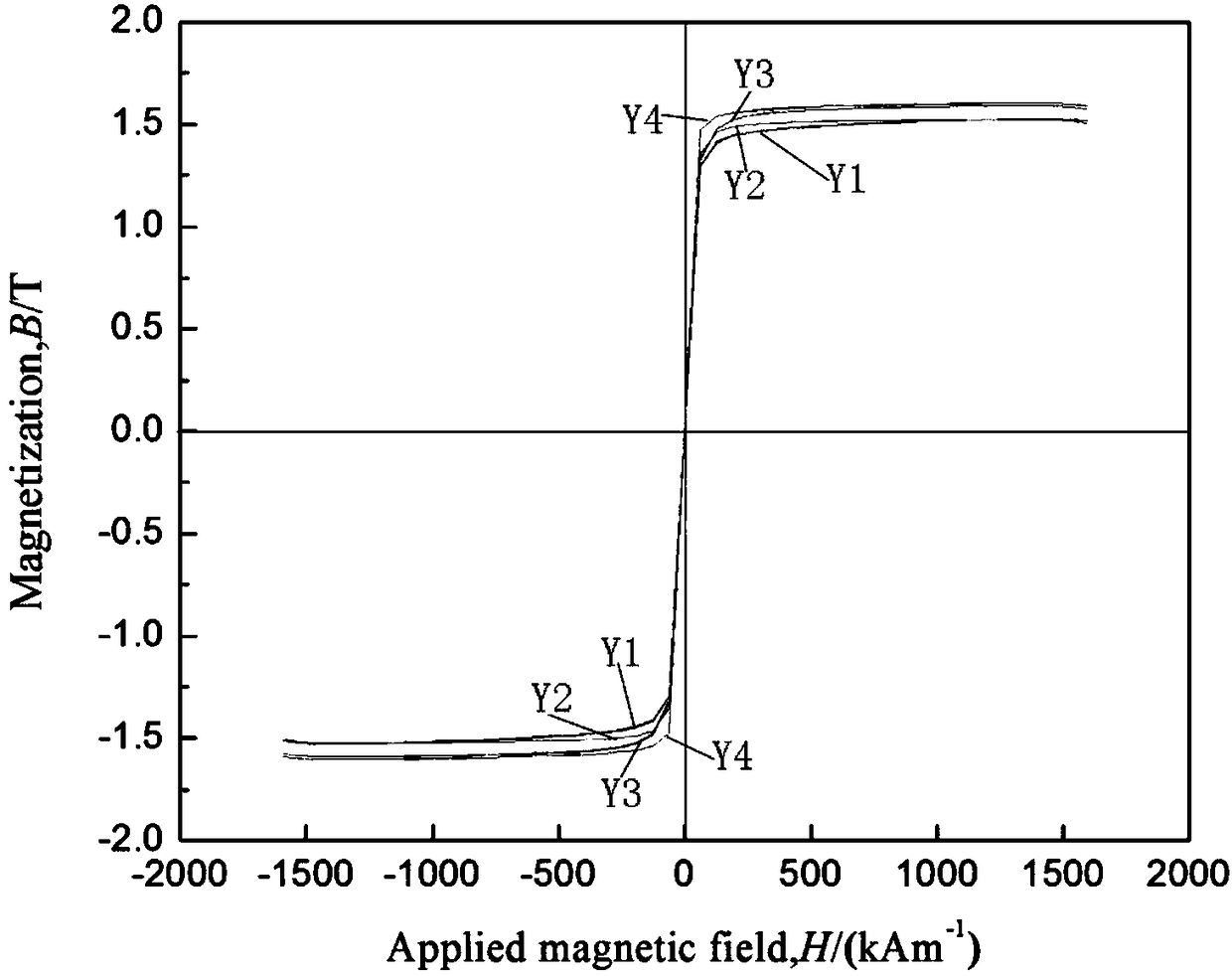

[0042] An iron-based amorphous soft magnetic alloy Fe with high saturation magnetic induction 78 Si 8.59 B 12.41 Ga 1 , denoted as Y1, its preparation method comprises the following steps:

[0043] 1) Ingredients: FeB with a purity of 99.9wt%, Si with a purity of 99.999wt%, FeB with a B content of 19.62wt%, and Ga with a purity of 99.99wt% are used for ingredients according to the atomic percentage content in the above alloy expression;

[0044] 2) Smelting master alloy: place the raw materials with a good ratio in a non-consumable vacuum electric arc furnace, and vacuumize to 4×10 - 3 Pa, filled with argon protective gas with a purity of 99.99%; adjust the current to 15A, refine the raw materials into master alloy ingots by arc melting, and repeatedly smelt the master alloy ingots 6 times to ensure the uniformity of the master alloy components, that is, iron base amorphous soft magnetic alloy;

[0045] 3) Strip preparation: under discontinuous production conditions, the...

Embodiment 2

[0050] An iron-based amorphous soft magnetic alloy Fe with high saturation magnetic induction 78 Si 8.18 B 11.82 Ga 2 , denoted as Y2, its preparation method comprises the following steps:

[0051] 1) Ingredients: FeB with a purity of 99.9wt%, Si with a purity of 99.999wt%, FeB with a B content of 19.62wt%, and Ga with a purity of 99.99wt% are used for ingredients according to the atomic percentage content in the above alloy expression;

[0052] 2) Smelting master alloy: Place the raw materials with a good ratio in a non-consumable vacuum electric arc furnace, and vacuumize to 5×10 - 3 Pa, filled with argon protective gas with a purity of 99.99%; adjust the current to 17A, refine the raw materials into master alloy ingots by arc melting, and repeatedly smelt the master alloy ingots 5 times to ensure the uniformity of the master alloy composition, that is, iron base amorphous soft magnetic alloy;

[0053] 3) Strip preparation: under discontinuous production conditions, th...

Embodiment 3

[0059] An iron-based amorphous soft magnetic alloy Fe with high saturation magnetic induction 78 Si 7.77 B11.23 Ga 3 , denoted as Y3, its preparation method comprises the following steps:

[0060] 1) Ingredients: FeB with a purity of 99.9wt%, Si with a purity of 99.999wt%, FeB with a B content of 19.62wt%, and Ga with a purity of 99.99wt% are used for ingredients according to the atomic percentage content in the above alloy expression;

[0061] 2) Smelting master alloy: Place the raw materials with a good ratio in a non-consumable vacuum electric arc furnace, and vacuumize to 4.5×10 -3 Pa, filled with argon protective gas with a purity of 99.99%; adjust the current to 25A, refine the raw materials into master alloy ingots by arc melting, and repeatedly smelt the master alloy ingots for 6 times to ensure the uniformity of the master alloy composition, that is, iron base amorphous soft magnetic alloy;

[0062] 3) Strip preparation: under discontinuous production conditions, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com