Preparation method of superparamagnetic polyimide composite film

A technology of superparamagnetic and composite films, which is applied in the field of preparation of superparamagnetic polyimide composite films, can solve the problems of low saturation magnetization, poor uniformity, irregular particle shape, etc., and achieve high magnetic saturation, distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

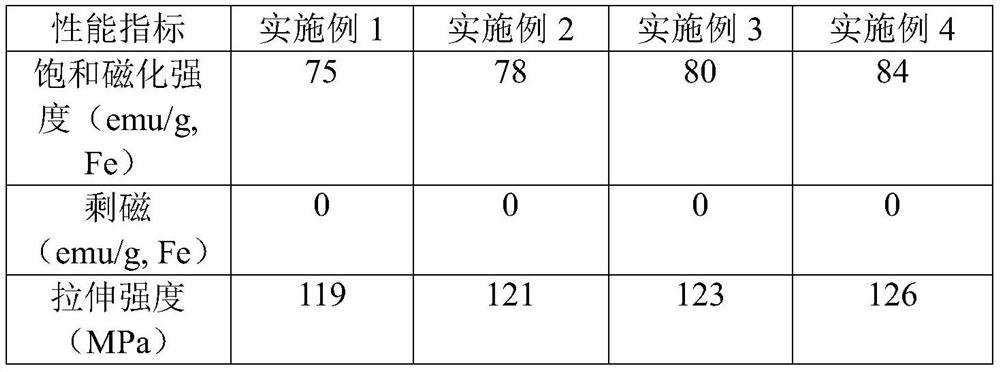

Examples

Embodiment 1

[0024] A preparation method of a superparamagnetic polyimide composite film, comprising the following steps:

[0025] Step 1. Add 1.5g iron acetylacetonate, 10g 1,2-hexadecyl glycol, 0.1g oleic acid, 0.1g oleylamine and 300g benzyl ether into the reactor and heat at a heating rate of 3.3°C / min to 200°C, keep it warm for 2 hours, then heat to the boiling point of benzyl ether, that is, reflux at 298°C for 1 hour, after the reaction is completed, cool to room temperature, add absolute ethanol to the reaction solution to obtain Fe 3 o 4 For magnetic nanoparticle precipitation, the precipitate was centrifuged at 3000rpm for 10min to remove the upper layer solution; to obtain Fe 3 o 4 magnetic nanoparticles;

[0026] Step two, 6g Fe 3 o 4 Magnetic nanoparticles were dispersed in 30mL of n-hexane, then 0.15g of 4-aminophenyltrimethoxysilane and 0.003g of glacial acetic acid were added dropwise and shaken for 72 hours to obtain a precipitate; the precipitate was separated by a m...

Embodiment 2

[0030] A preparation method of a superparamagnetic polyimide composite film, comprising the following steps:

[0031] Step 1. Add 1.5g iron acetylacetonate, 10g 1,2-hexadecyl glycol, 0.1g oleic acid, 0.1g oleylamine and 300g benzyl ether into the reactor and heat at a heating rate of 3.3°C / min to 200°C, keep it warm for 2 hours, then heat to the boiling point of benzyl ether, that is, reflux at 298°C for 1 hour, after the reaction is completed, cool to room temperature, add absolute ethanol to the reaction solution to obtain Fe 3 o4 For magnetic nanoparticle precipitation, the precipitate was centrifuged at 3000rpm for 10min to remove the upper layer solution; to obtain Fe 3 o 4 Magnetic nanoparticles; Fe obtained by low-temperature plasma 3 o 4 Magnetic nanoparticles are processed, the process is: the Fe 3 o 4 The magnetic nanoparticles are placed in the low-temperature plasma treatment reaction chamber, and the vacuum pump is turned on. After the vacuum degree in the ch...

Embodiment 3

[0036] A preparation method of a superparamagnetic polyimide composite film, comprising the following steps:

[0037] Step 1. Add 1.5g iron acetylacetonate, 10g 1,2-hexadecyl glycol, 0.1g oleic acid, 0.1g oleylamine and 300g benzyl ether into the reactor and heat at a heating rate of 3.3°C / min to 200°C, keep it warm for 2 hours, then heat to the boiling point of benzyl ether, that is, reflux at 298°C for 1 hour, after the reaction is completed, cool to room temperature, add absolute ethanol to the reaction solution to obtain Fe 3 o 4 For magnetic nanoparticle precipitation, the precipitate was centrifuged at 3000rpm for 10min to remove the upper layer solution; to obtain Fe 3 o 4 Magnetic nanoparticles; Fe obtained by low-temperature plasma 3 o 4 Magnetic nanoparticles are processed, the process is: the Fe 3 o 4 The magnetic nanoparticles are placed in the low-temperature plasma treatment reaction chamber, and the vacuum pump is turned on. After the vacuum degree in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com