Apparatus and process for production of liquid fuel from biomass

A liquid fuel and biomass technology, which is applied in the preparation of biofuels, liquid carbon-containing fuels, and liquid hydrocarbon mixtures, etc., can solve the problems of inefficient synthesis of methanol gas, time-consuming maintenance, and difficulty in adjusting temperature, etc., to achieve improved synthesis The effect of yield rate, less mechanical problems, and stable operation of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Hereinafter, the present invention will be specifically described with reference to the drawings. In addition, in the embodiment, the case where the liquid fuel is methanol will be described as an example.

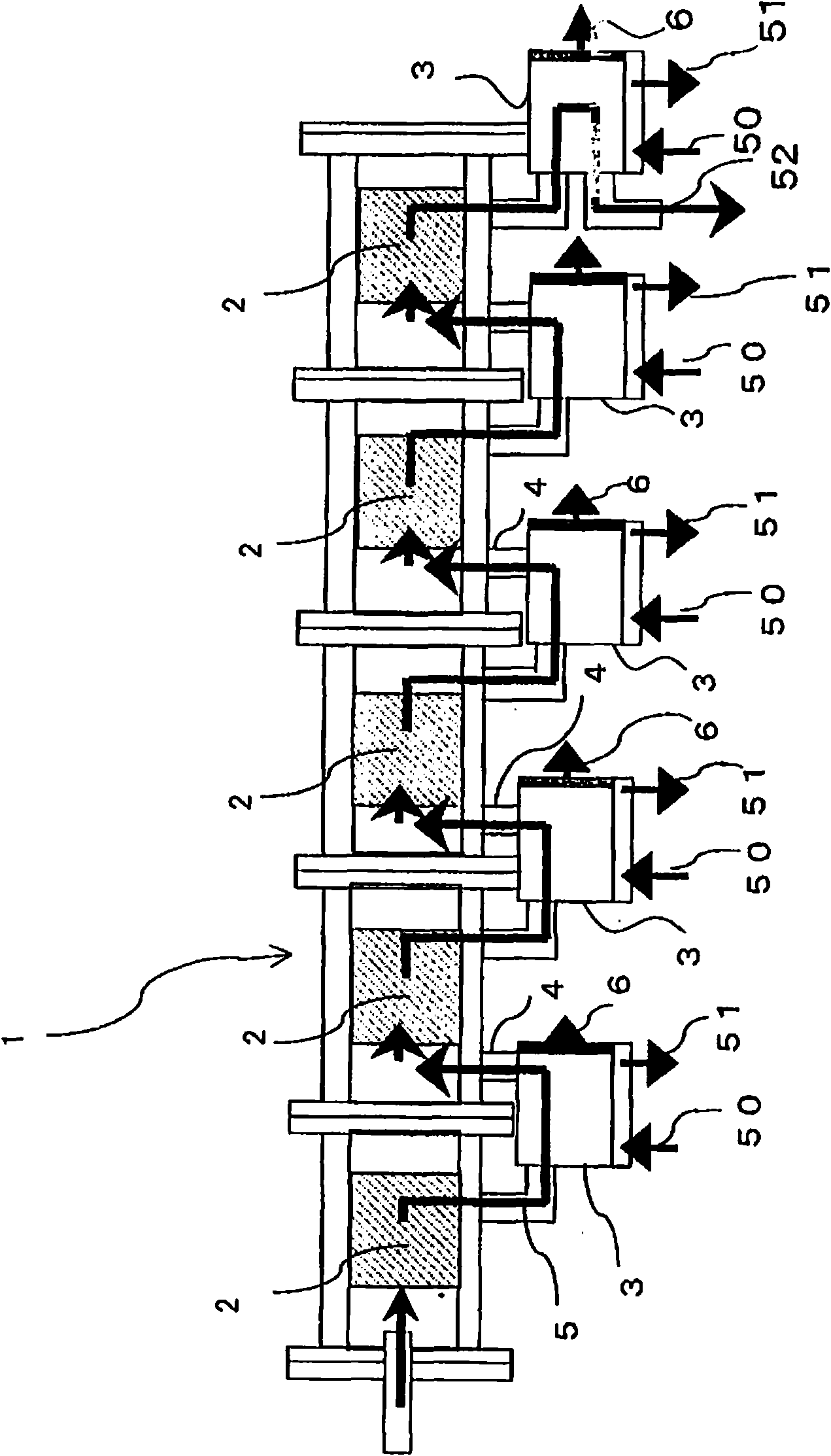

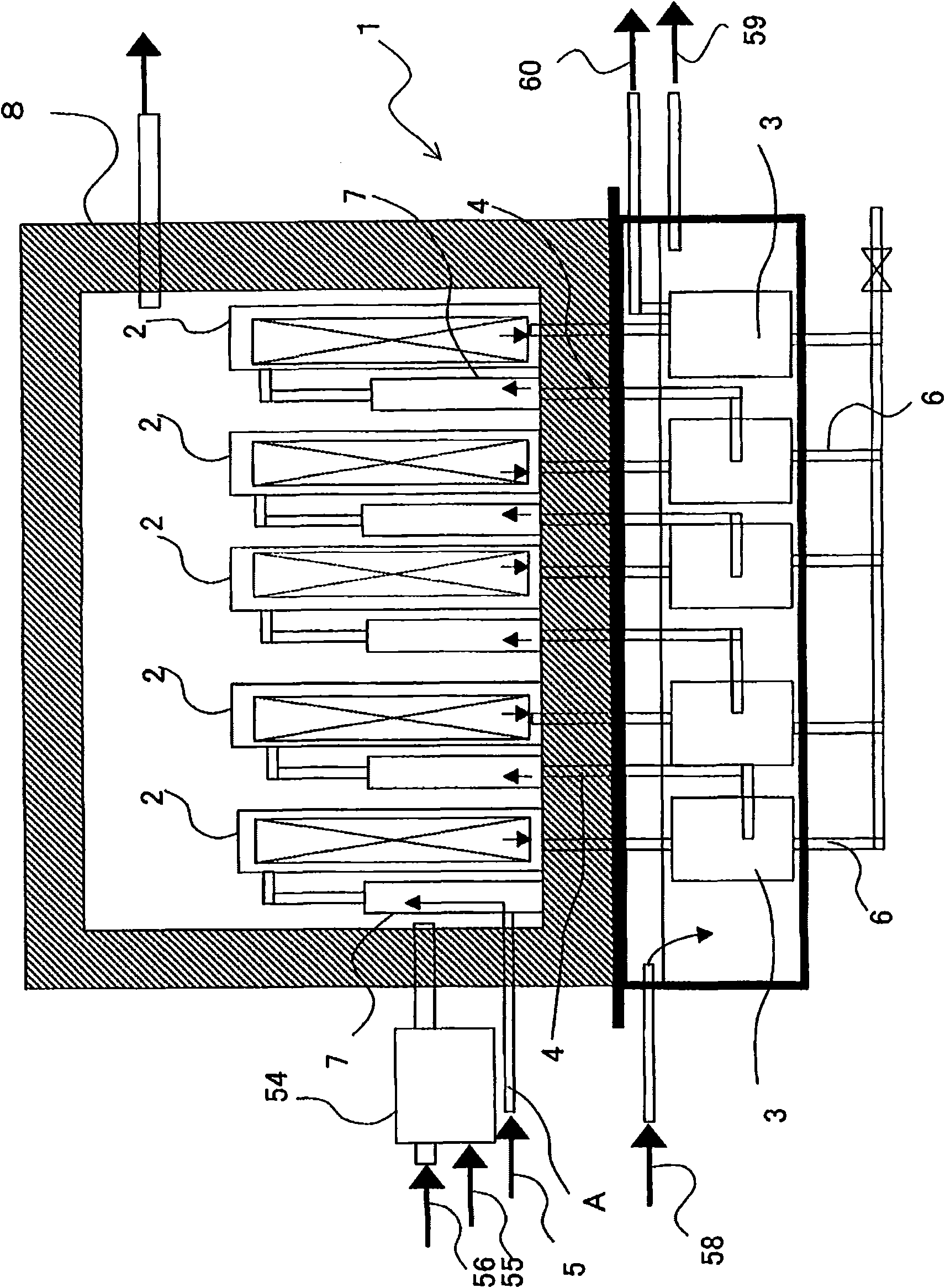

[0068] figure 1 A schematic diagram showing a multi-stage liquid fuel synthesis basic experimental device as the first embodiment of the present invention. A liquid fuel synthesis device usually comprises a plurality of reactors 2 in 3 to 10 stages. In the example in this figure, it consists of 5 stages. They are arranged in series with respect to the airflow.

[0069] A synthesis gas supply pipe 4 is connected to the upstream side of the reactor 2 , and a reaction gas outlet pipe 5 is connected to the downstream side thereof to be connected to the cooler 3 . Synthesis gas, which is a synthesis raw material for liquid fuel, is supplied to the reactor 2 from a synthesis gas supply pipe 4 . In addition, a synthesis raw material gas supply line A is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com