Energy-saving environment-friendly rolling mill guiding device

An energy saving, environmental protection, rolling mill technology, applied in the direction of keeping the roll equipment in an effective state, metal processing equipment, metal rolling, etc., can solve the problems of single function, reduce the operating rate of the rolling mill, poor rigidity and adjustability, and achieve safe and convenient operation. , the effect of improving work efficiency and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

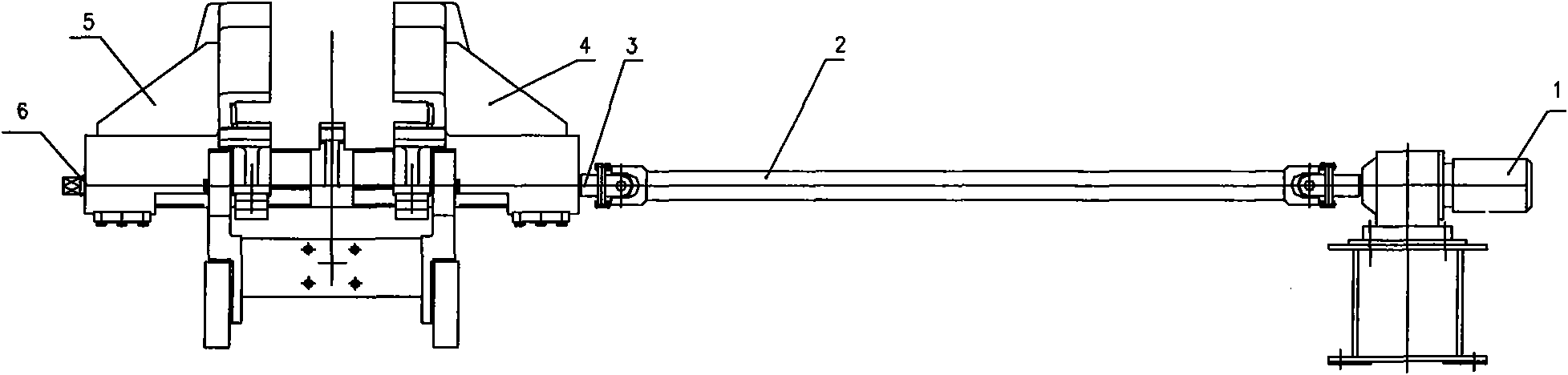

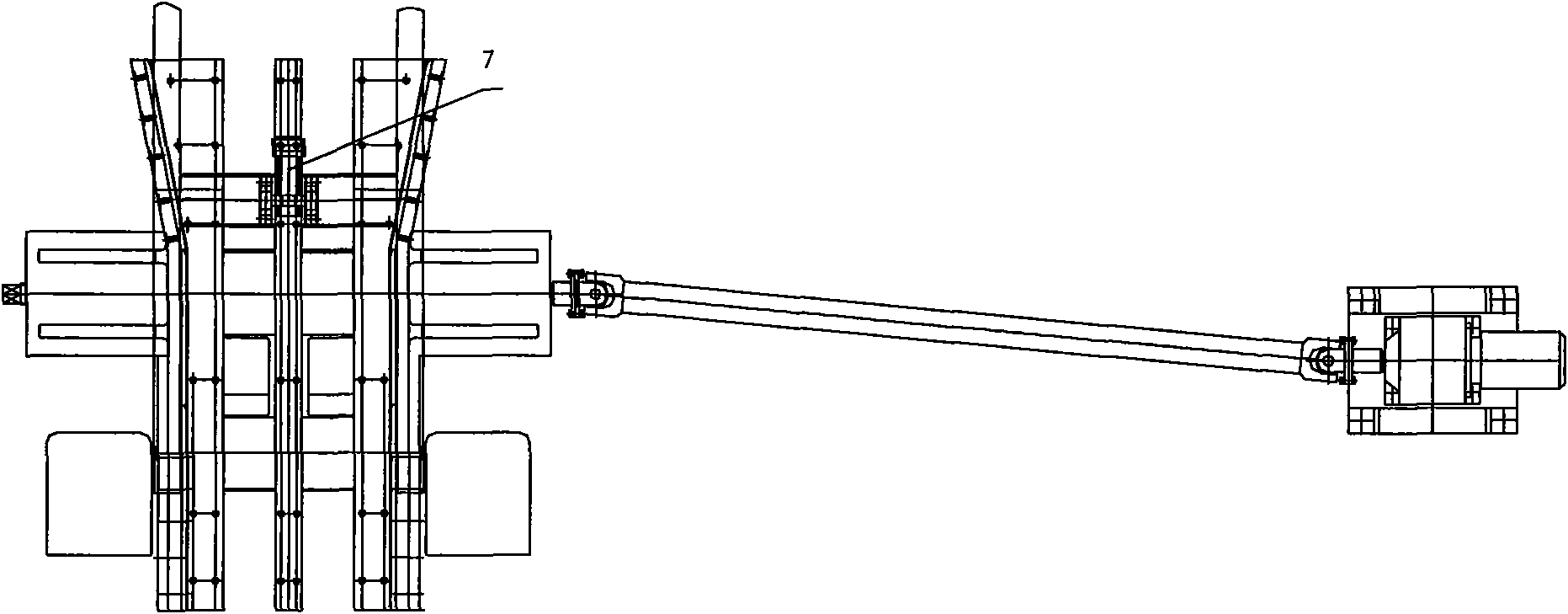

[0026] See figure 1 , figure 2 , an energy-saving and environment-friendly rolling mill guide equipment, including an entrance guide and an exit guide, the entrance guide includes a left side wall 5, a right side wall 4, and the difference between the left side wall 5 and the right side wall 4 can be adjusted according to the width of a rolled piece distance control system.

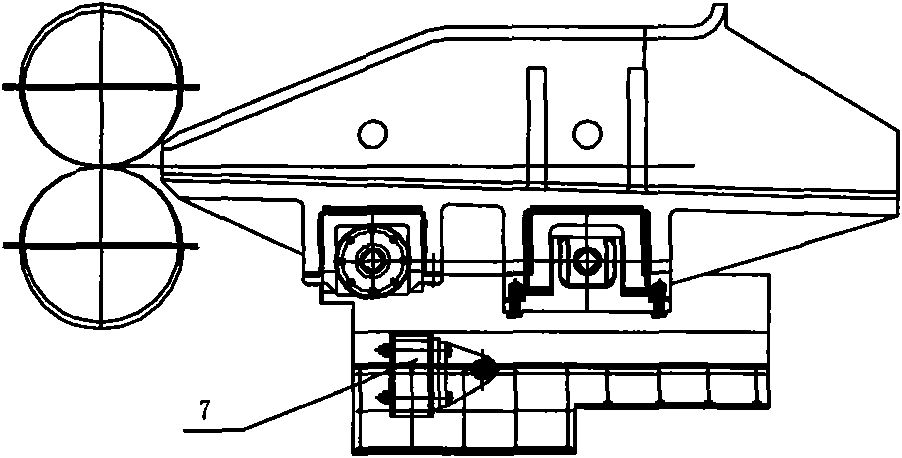

[0027] See Image 6 , the control system is a closed-loop system composed of computer, interface card, driver, servo motor, lead screw, code disc, and interface card. The sensor transmits the width signal of the rolled piece to the computer, and the computer sends a control signal through the interface card according to the width signal. For the driver, the servo motor drives the lead screw to work through the driver, and the distance driven by the lead screw is transmitted to the computer by the interface card through the code disc. See Figure 3-1 , Figure 3-2 , Figure 3-3 , Lead screw comprise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com