Quaternary Pb-free solder composition incorporating Sn-Ag-Cu-In

A technology of lead-free solder and composition, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., and can solve the problem of decreased alloy strength and creep resistance, and increased difference between liquidus temperature and solidus temperature , Slow breakage of solder joints, etc., to improve thermal cycle resistance and mechanical shock resistance, prevent wettability reduction, and save manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

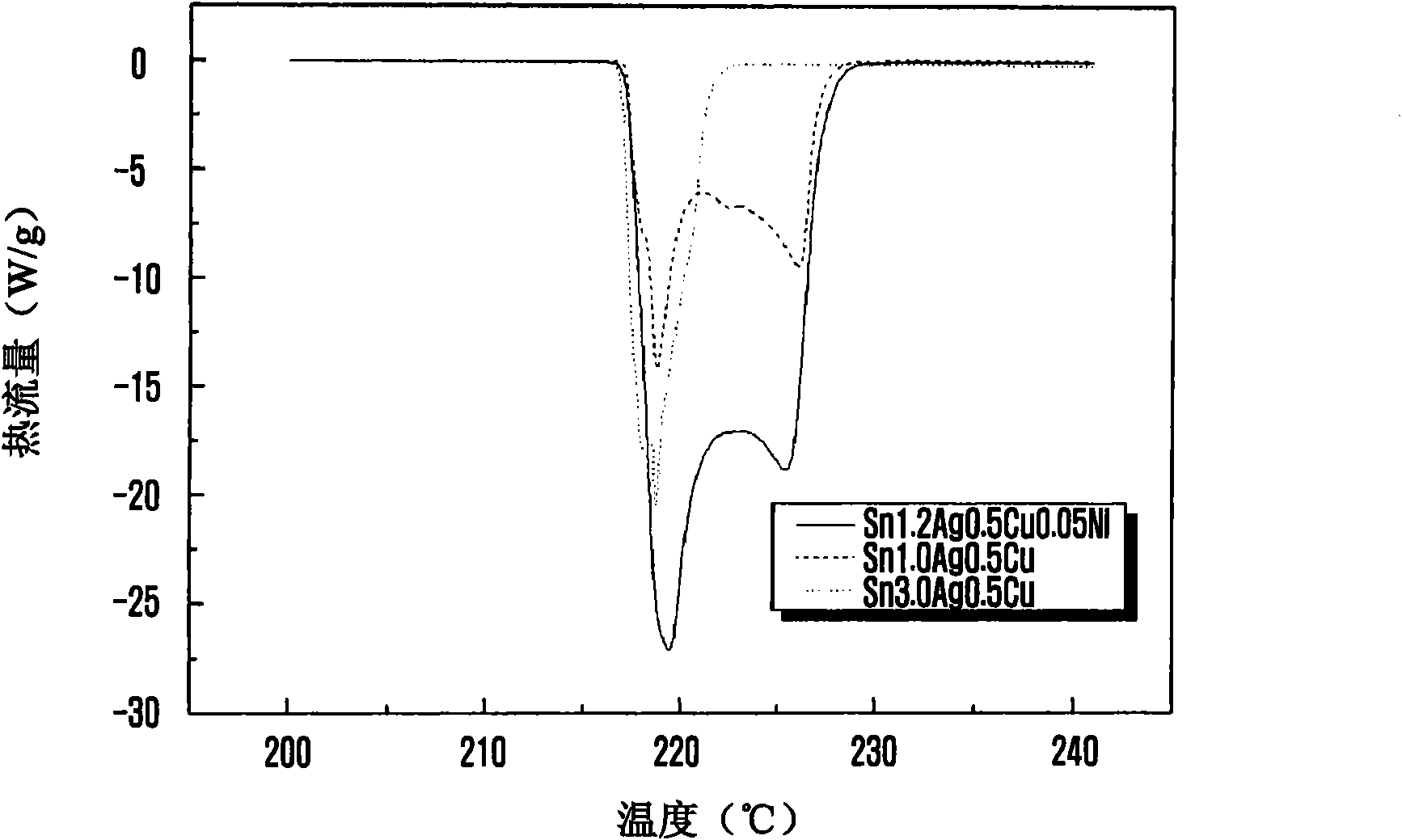

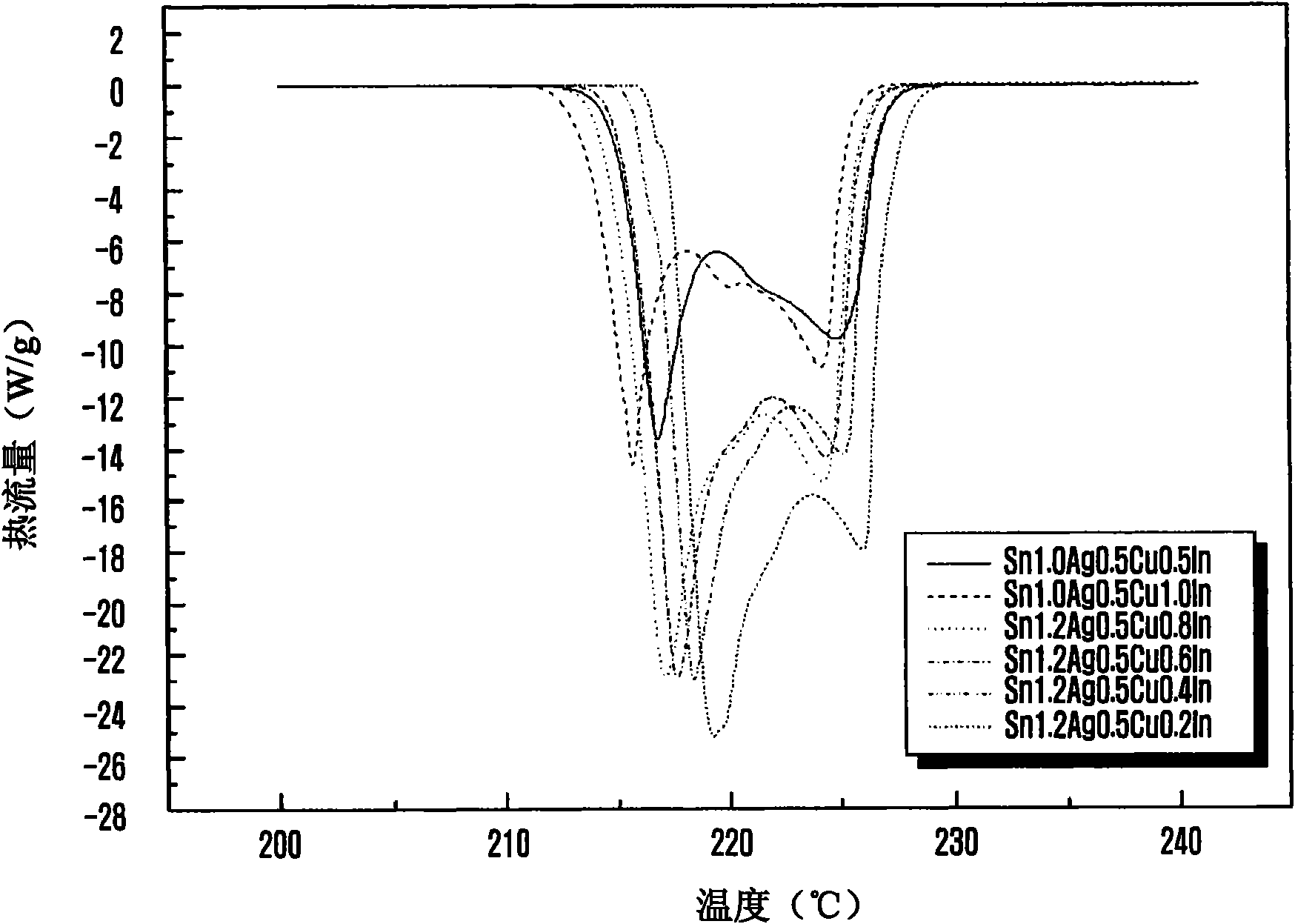

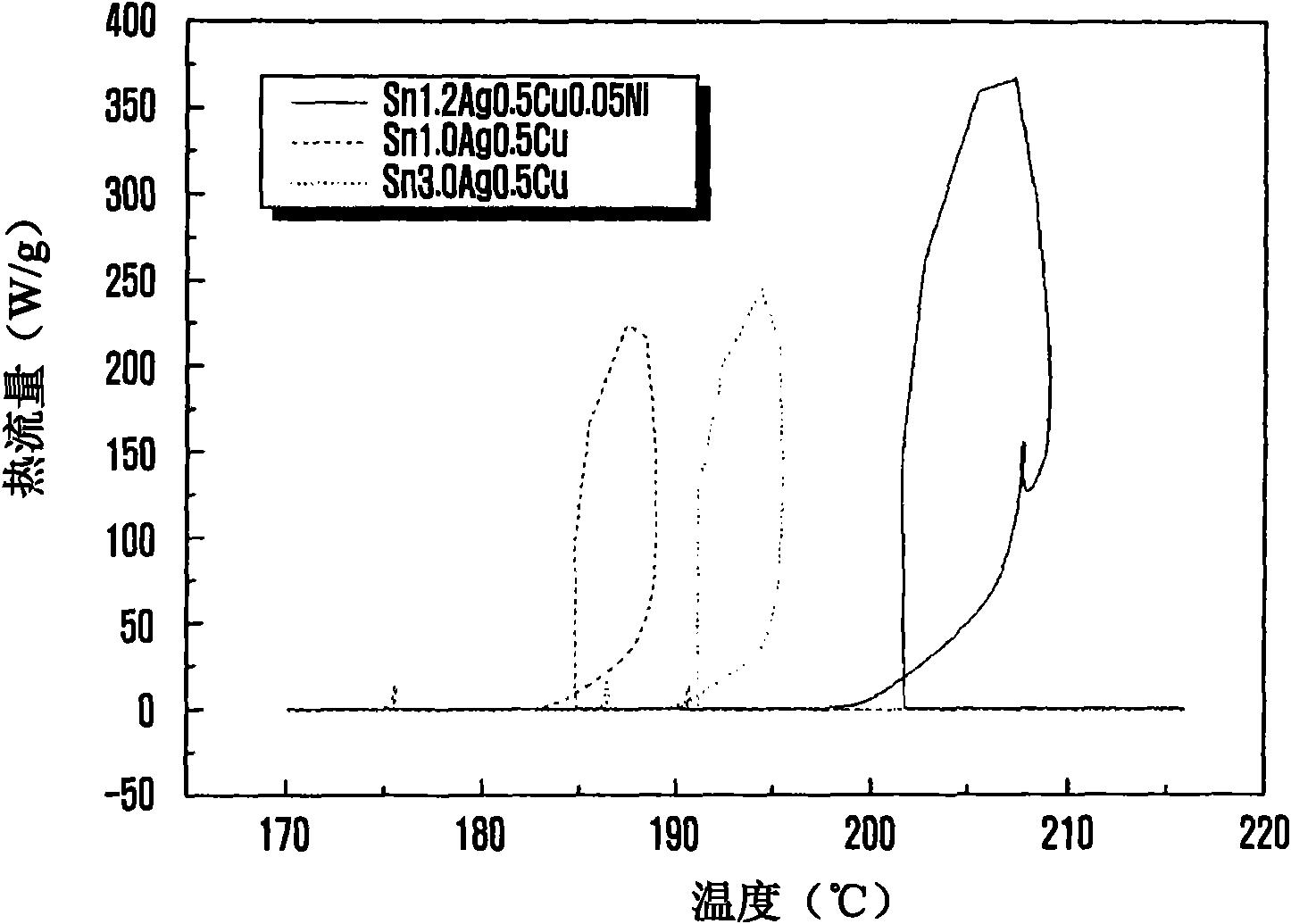

[0033] Hereinafter, the tin-silver-copper-indium (Sn-Ag-Cu-In) quaternary lead (Pb)-free solder composition of the present invention will be described in detail with reference to the accompanying drawings. Hereinafter, when it is considered that specific descriptions about known functions or structures will unnecessarily obscure the gist of the present invention, the specific descriptions will be omitted.

[0034] In the lead-free solder composition of the present invention, the weight percent of Ag is less than about 2.5% by weight but not less than about 0.3% by weight. If the weight percentage of Ag is less than 0.3 wt%, it is difficult to lower the liquidus temperature, resulting in an increase in the melting point of the solder and the packaging processing temperature. On the contrary, if the weight percent of Ag is 2.5% by weight or more, the manufacturing cost may disadvantageously increase. Therefore, the weight percent of Ag should be less than about 2.5 wt% but not ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com