Welding manipulator

A welding manipulator and articulation technology, applied in manipulators, program-controlled manipulators, welding equipment, etc., can solve the problems of low production efficiency of manual welding, affecting product manufacturing quality, and high labor intensity of workers, achieving light weight, low cost, welding Stable quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

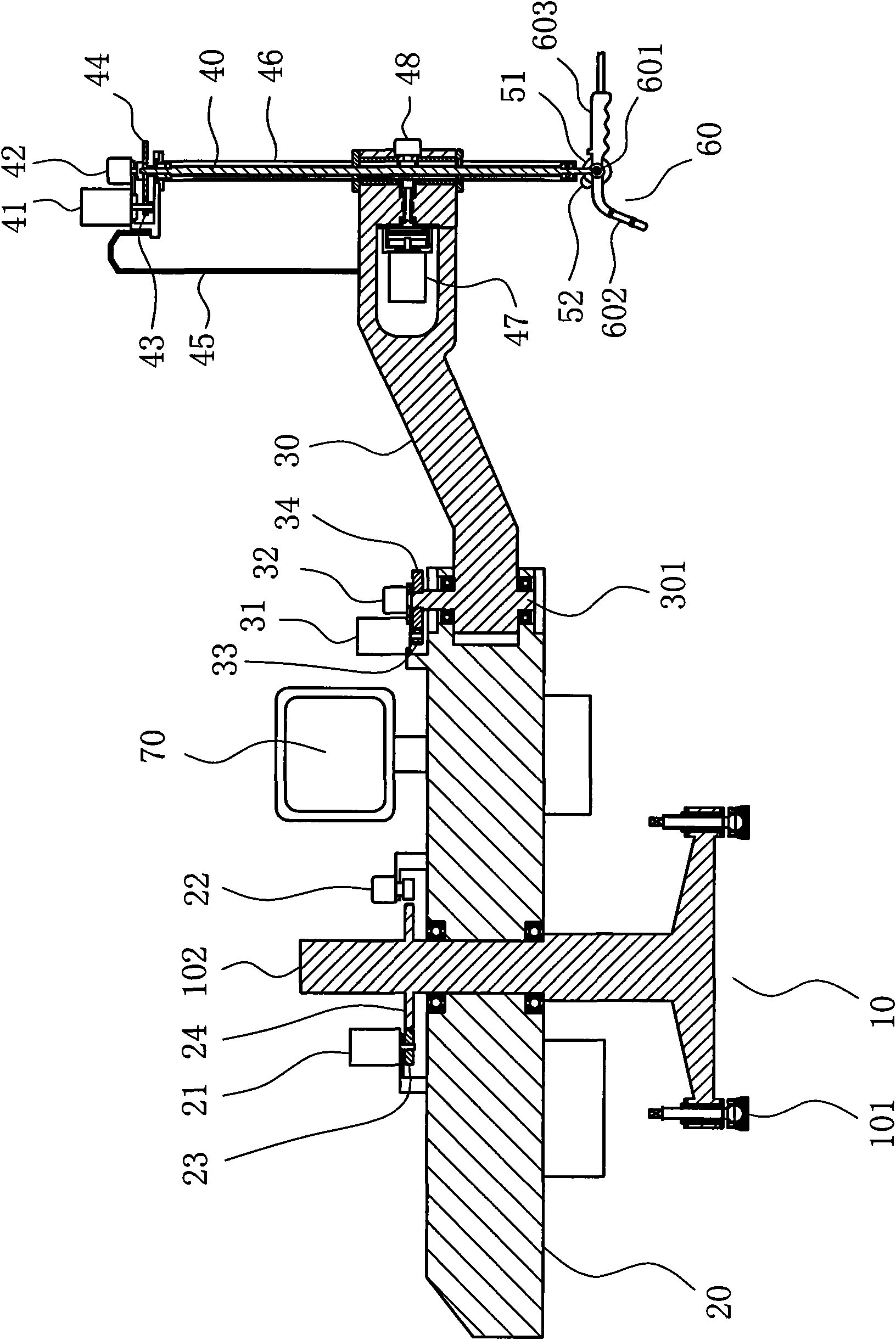

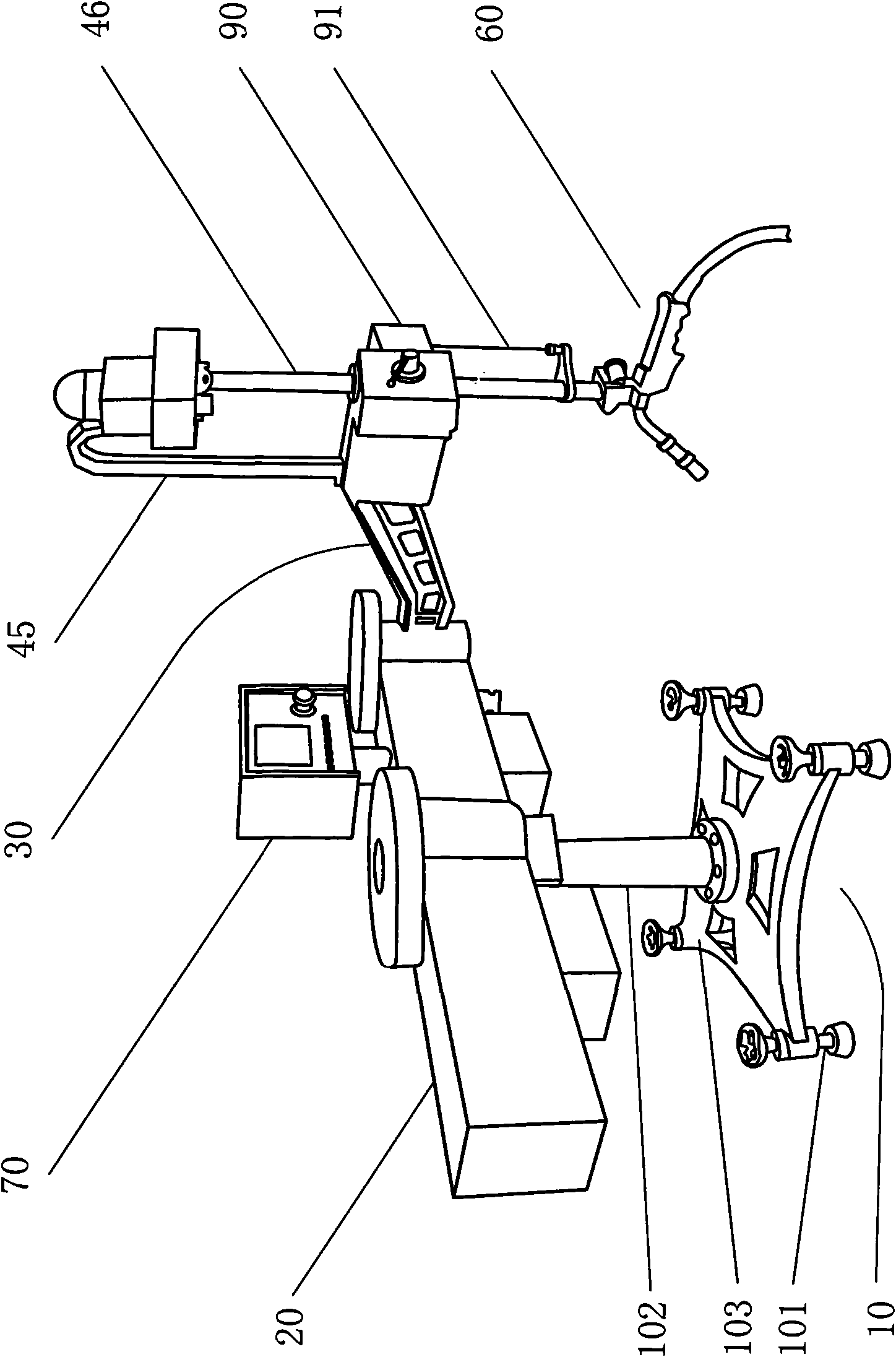

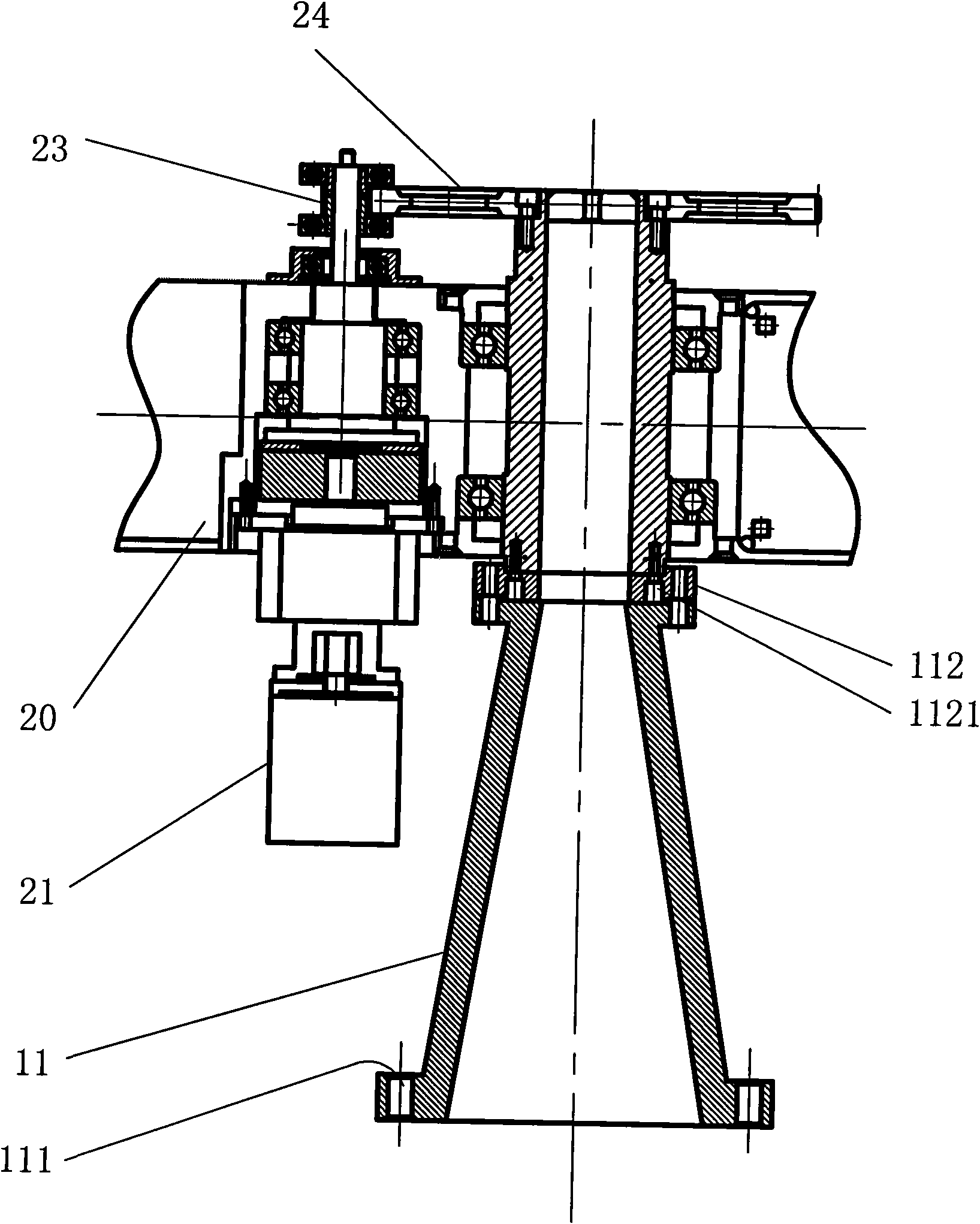

[0022] The present invention will be further described below with specific embodiment, see Figure 1-4 :

[0023] The welding manipulator includes a base 10 and a motor. A vertical shaft 102 is provided on the base 10. A large rocker arm 20 that can rotate around it is provided on the vertical shaft 102. One end of the large rocker arm 20 is hinged to a The small rocker arm 30 is provided with a vertical shaft 40 at the outer end of the small rocker arm 30, an outer shaft 46 is arranged outside the vertical shaft 40, and a welding torch head 60 is hinged at the lower end of the vertical shaft 40. The large rocker arm 20 and the small rocker arm 30 The rotation of the vertical shaft 40 and the lifting of the vertical shaft 40 are all driven by the motors 21, 31, 41, 47 that are set independently, and are collected or measured by the independent encoders 22, 32, 42, 48. The rotation angle and the lifting displacement signal , the swing of welding torch head 60 is driven by moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com