Polar-molecule type electro-rheological fluid and preparation method thereof

An electrorheological fluid, molecular technology, applied in the petroleum industry, base materials, additives, etc., can solve the problems of lack of explanation, unclear understanding of the origin of high yield stress of electrorheological fluid materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

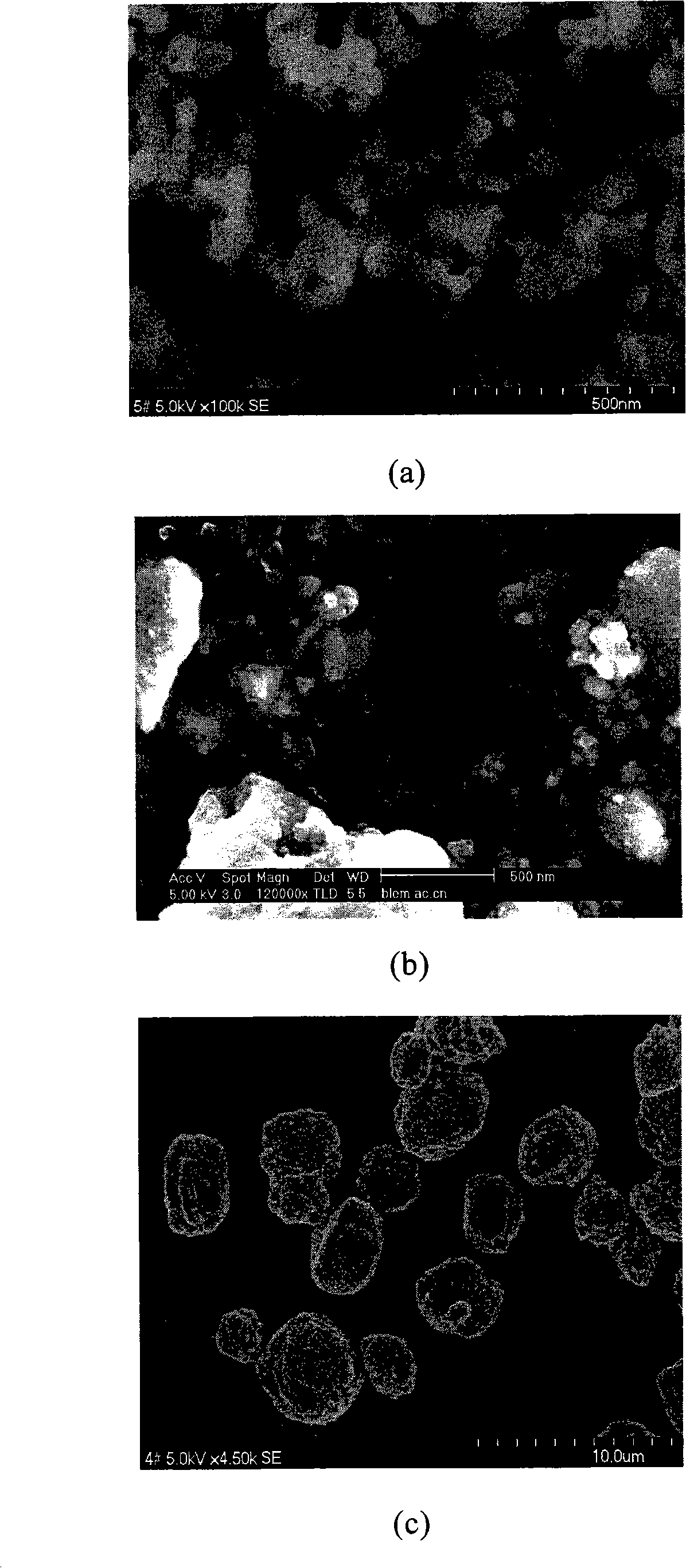

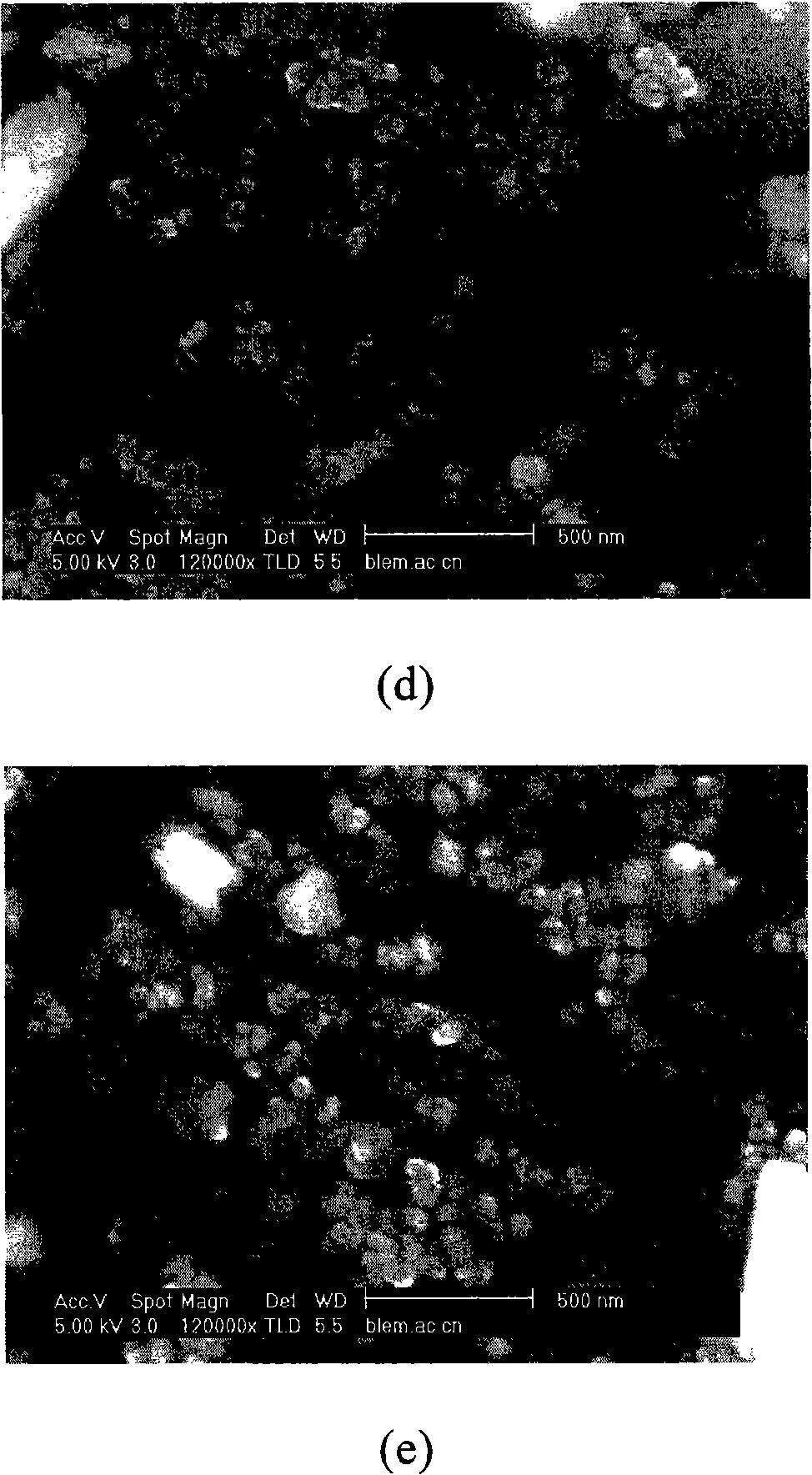

[0029] 25g LaCl 3 ·7H 2 O, 23ml Ti(OC 4 h 9 ) 4 Dissolve in 400ml of absolute ethanol to prepare solution A; dissolve 13g of oxalic acid dihydrate in a mixture of 200ml deionized water and 200ml of absolute ethanol to prepare solution B. Add solution A to solution B at 40-65°C with ultrasound or strong stirring to obtain a white precipitate, wash and filter the precipitate with deionized water, and dry at 50-150°C to remove traces of water , to obtain white carbonyl-containing LaTiO(C 2 o 4 ) 1.5 Granules (LTO Granules). Its particle shape is as figure 1 As shown in a, the LTO particles are irregular in shape, and the particle size is about 100 nm.

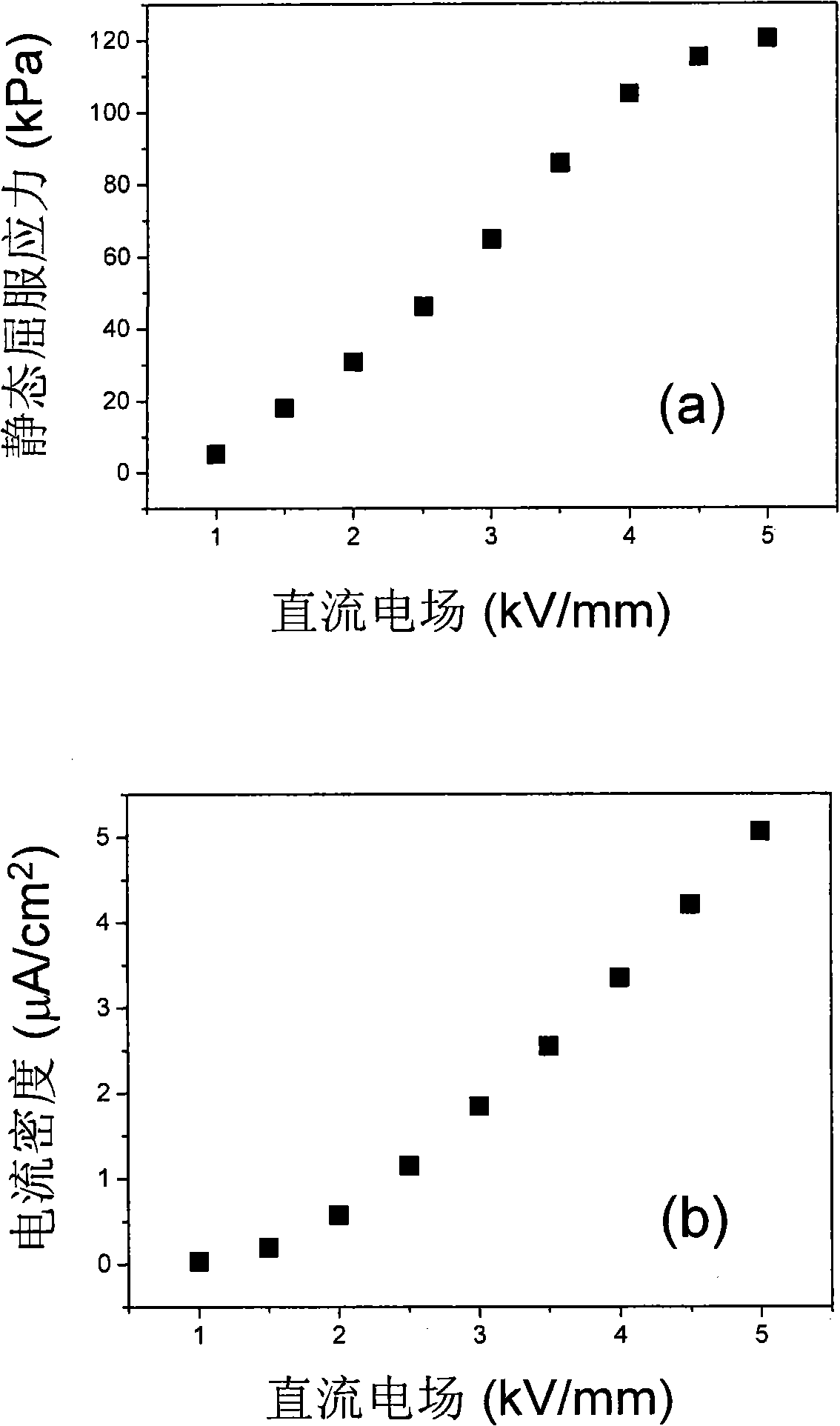

[0030]The prepared LTO particles with a viscosity of 10mm 2 The simethicone oil per s is fully mixed evenly, and the volume percentage of particles is 40%. The relationship between the static yield stress and current density and the applied DC electric field is as follows figure 2 (a) and 2(b). When the applied DC ele...

Embodiment 2

[0032] 2.22gLiCl·H 2 O, 13.6g LaCl 3 ·7H 2 O, 25ml Ti(OC 4 h 9 ) 4 Dissolve in 300ml of absolute ethanol to prepare solution A; dissolve 16.67g of oxalic acid dihydrate in a mixture of 200ml deionized water and 200ml of absolute ethanol to prepare solution B. Add solution A to solution B at 40-65°C with ultrasound or strong stirring to obtain a white precipitate, age the precipitate in a water bath at 40-65°C for 3 hours, wash and filter with deionized water, and Dry at 50-150°C to remove traces of water to obtain white carbonyl-containing Li 0.5 La 0.5 TiO(C 2 o 4 ) 1.8 (LLTO) particles. Its particle shape is as figure 1 As shown in b, the LLTO particles are in the shape of a class, and some particles are agglomerated, and the particle size is about 50 nm.

[0033] The prepared LLTO particles with a viscosity of 200mm 2 The simethicone oil per s is fully mixed evenly, and the volume percentage of particles is 40%. The relationship between the static yield stress ...

Embodiment 3

[0035] 30ml Ti(OC 4 h 9 ) 4 Dissolve in 200ml of absolute ethanol to obtain solution A, and place it in an ice-water bath for later use; dissolve 22.2g of oxalic acid dihydrate in a mixture of 200ml of absolute ethanol and 250ml of deionized water to make solution B; 23.5g of SrCl 2 ·6H 2 O was mixed with 60ml deionized water to make solution C. After the three solutions were fully stirred, 6ml of hydrochloric acid was added to solution C, and poured into solution A, fully stirred in an ice-water bath until the mixture was uniform, and clear light yellow solution D was obtained. Heat solution B to 60°C, drop solution D into solution B, and keep constant temperature during the titration reaction. After the titration, the resulting suspension was aged in a water bath at 40 °C for 3 h. Wash and centrifuge with deionized water, dry at 50-150°C, remove trace water, and obtain white carbonyl-containing SrTiO(C 2 o 4 ) 2 (STO) particles. The morphology of STO particles is as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Scale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com