Method for manufacturing organic fertilizer by utilizing sludge

An organic fertilizer and sludge technology, applied in the field of aerobic fermentation engineering, can solve the problems of low reduction effect, high investment and operation cost, serious nitrogen loss, etc. The effect of promoting growth and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

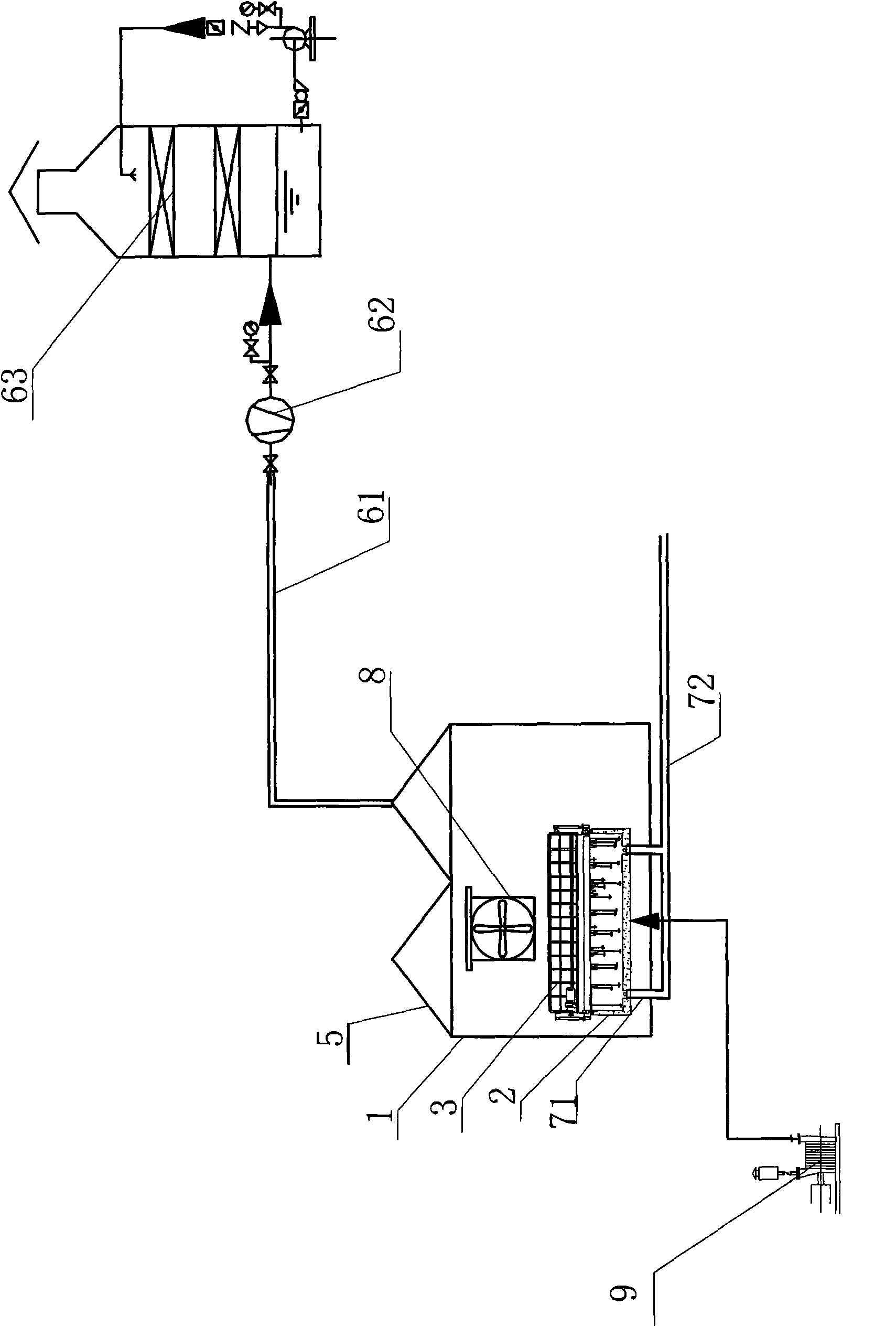

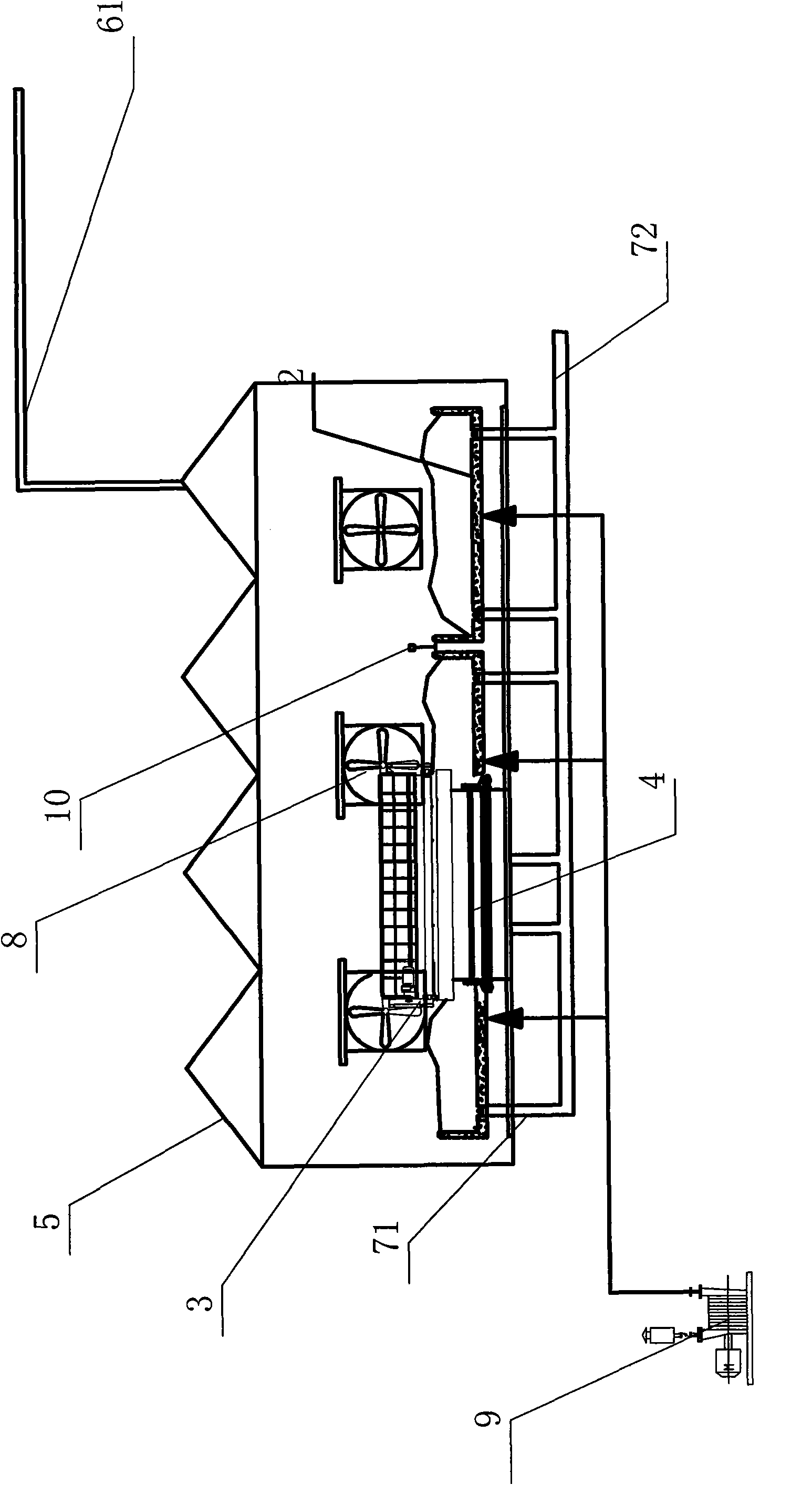

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: provide a kind of method utilizing sludge to produce organic fertilizer, this method comprises the following steps:

[0051] 1) Add an additive with a water content of 15% and a weight ratio of 30% to the sludge with a water content of 80% and a weight ratio of 70% after pressure filtration dehydration.

[0052] 2) The obtained mixture is piled up and fermented for 24 days, and turned over and thrown 4 times a day;

[0053] 3) get rid of the moisture content that mixture produces in the fermentation;

[0054] 4) increase the air content to accelerate the fermentation of the mixture;

[0055] 5) Deodorization;

[0056] 6) The fermented mixture is an organic fertilizer, which is then made into a granular fertilizer product.

[0057] The specific steps of the mixture fermentation obtained in the described step 2):

[0058] a) The mixture was fermented for 2 days under the condition that the temperature gradually increased from normal temperature to 55°C. ...

Embodiment 2

[0064] Example 2 is the same as Example 1, except that in step 2) the mixture obtained is piled up and fermented for 42 days, and turned over and thrown twice a day; Proceed as follows:

[0065] a) The mixture was fermented for 3 days under the condition that the temperature gradually increased from normal temperature to 55°C.

[0066] b) Under the condition of keeping the temperature at 55° C., the mixture was fermented again for 9 days.

[0067] c) the temperature is lowered to normal temperature, and the mixture is finally fermented for 30 days.

[0068] Step 6) described in embodiment 1) the mixture that finishes fermentation is organic fertilizer, and then it is made into powdery fertilizer finished product. In the specific steps of mixture fermentation, step d) that is also included after step c) is to lower the temperature to normal temperature, at this time, the temperature of the mixture is maintained at normal temperature, and the number of times of turning over th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com