Biomass direct thermal cracking generator and cracking method thereof

A thermal cracking and generator technology, used in chemical instruments and methods, biofuels, indirect heating and dry distillation, etc., can solve the problems of low thermal efficiency, high energy consumption cost, high transportation power, etc., to increase the heating contact area, overcome the Thermal inefficiency, the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention and the operation mode of the equipment will be described in detail below in conjunction with the accompanying drawings and embodiments.

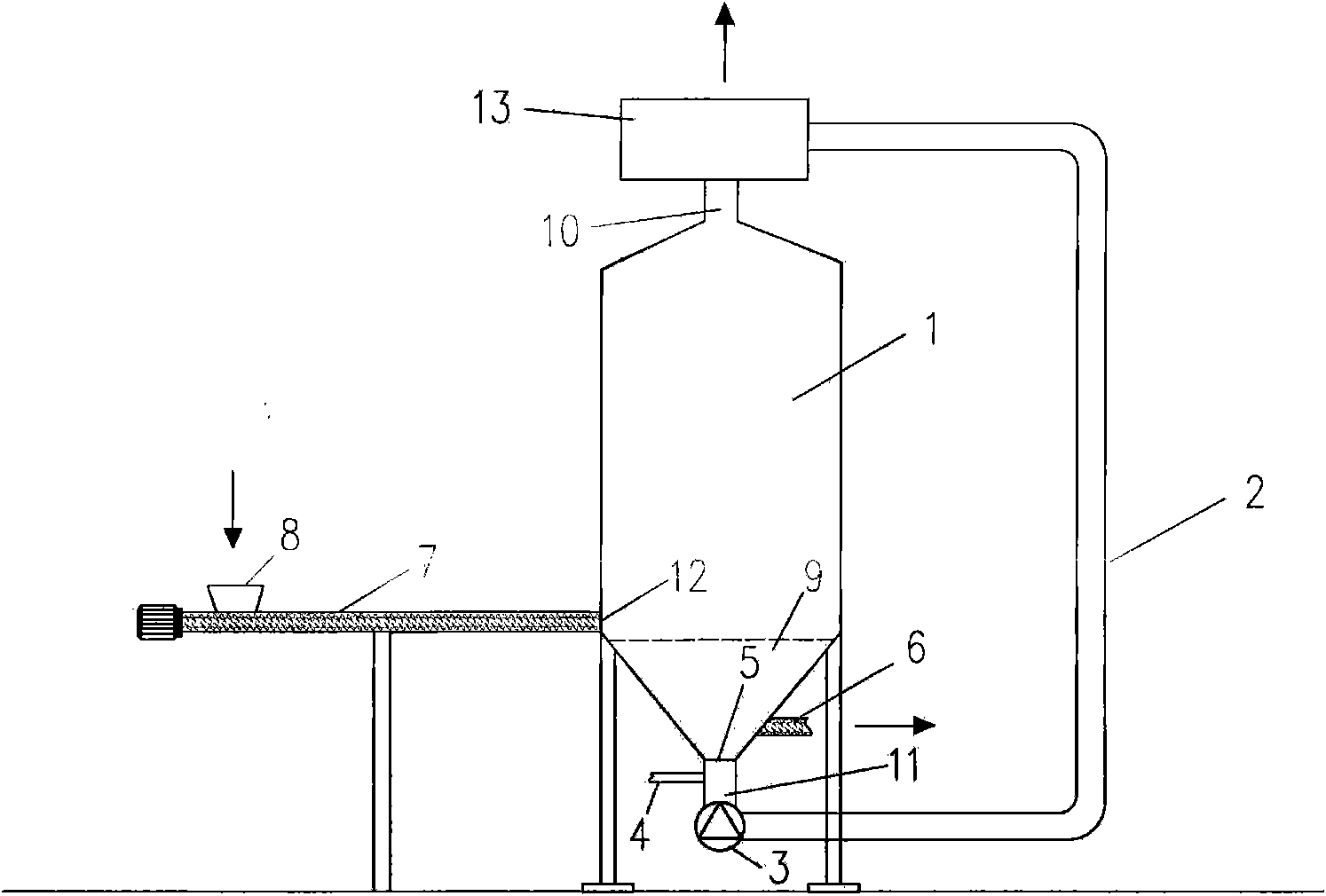

[0018] Such as figure 1 Shown is a schematic structural diagram of the biomass direct pyrolysis generator used in the present invention. The generator comprises: a thermal cracking reaction chamber 1, a gas delivery pump 3 arranged at its lower part, a gas return burning pipe 2 connected to the gas outlet 10 side on the upper part of the thermal cracking reaction chamber 1, and the gas burning back pipe 2 passes through The fuel gas delivery pump 3 is connected to the combustion heating chamber 9 positioned below the thermal cracking reaction chamber 1, the thermal cracking reaction chamber 1 and the combustion heating chamber 9 are divided due to different functions, and there is no actual partition between them to separate, from The burn-back gas input from the gas burn-back pipe 2 and the oxygen input throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com