Burner, burning heating method and burning heating equipment

A technology of a burner and a burner plate is applied in the field of combustion heating method, combustion heating equipment, and burner, which can solve the problems of high ineffective power consumption, affecting work efficiency, low thermal efficiency, etc., so as to avoid diffusion, reduce energy consumption, and improve The effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

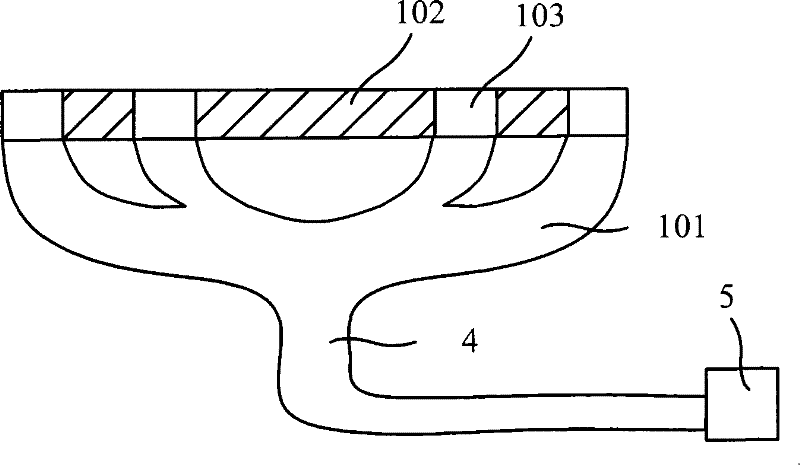

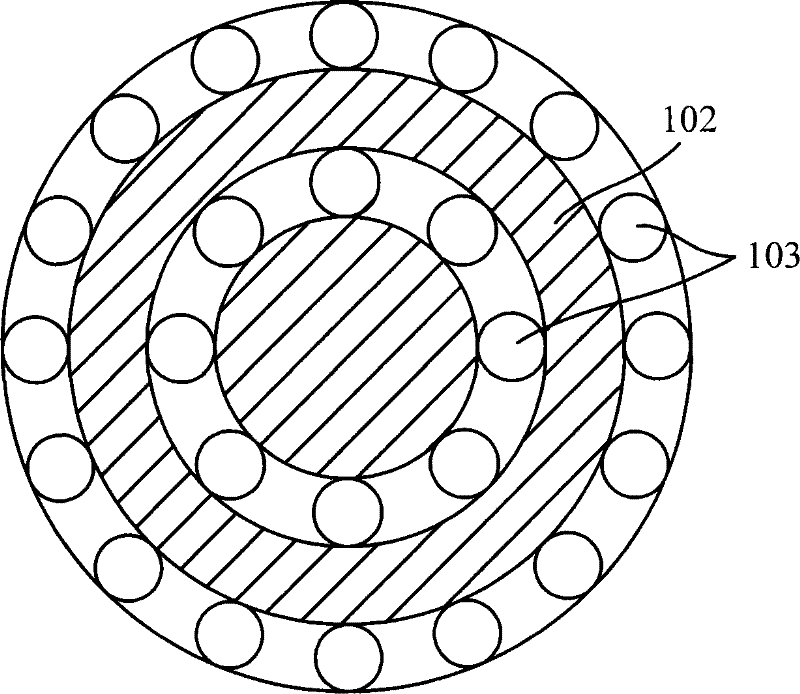

[0044] Such as image 3 Shown is a schematic structural view of the first embodiment of the burner of the present invention. The burner in this embodiment includes a distribution chamber 301 and a plurality of gas mixing pipes 302 . Wherein, the distributing chamber 301 can be formed by a disc-shaped connecting seat 303 and a disc-shaped cooktop base 304 that are relatively fastened together, so as to form a cavity 309 inside the distributing chamber 301 . A gas inlet 305 is provided on the wall of the distribution chamber 301, such as image 3 As shown, the gas inlet 305 can be set on the stove base 304 as the lower end surface of the distribution chamber 301 , and the cavity 309 in the distribution chamber 301 communicates with the gas pipeline 4 of the gas source 5 through the gas inlet 305 . A plurality of gas outlets 306 are arranged on the connection seat 303 as the upper end surface of the distribution chamber 301, and each gas outlet 306 is respectively provided with...

Embodiment 2

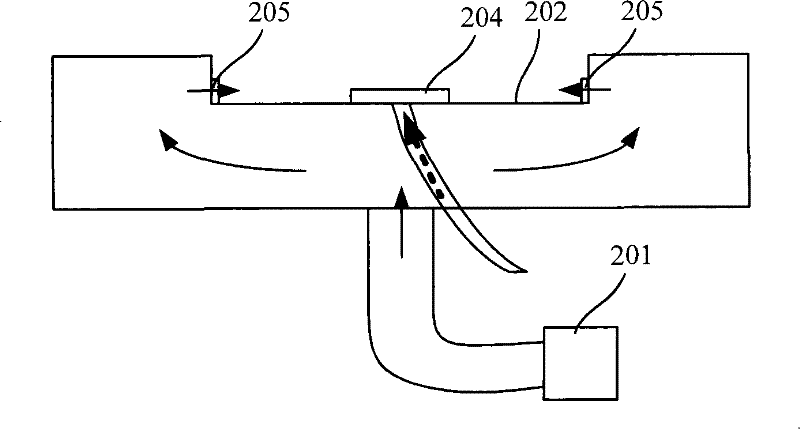

[0055] Such as Figure 5 Shown is the structural schematic diagram of the second embodiment of the burner of the present invention. This embodiment is based on the first embodiment, a combustion disc 311 is set in the burner, a plurality of combustion through holes 313 are opened on the combustion disc 311, and the outlet ends of each gas mixing pipe 302 are embedded and fixed on the combustion disc 311 In each of the combustion through holes 313, the combustion disc 311 is exposed through the combustion through holes 313, and is used to provide the mixed gas to burn on the combustion disc 311.

[0056] The setting of the combustion disc 311 can fix the outlet ends of the gas mixing pipes 302 and concentrate the combustion flame, which is suitable for the requirements of common combustion heating equipment. Moreover, the setting of the combustion disc 311 can relatively isolate the flame from the gas mixing tube 302, and has a protective effect on the gas mixing tube 302, red...

Embodiment 3

[0059] Such as Figure 6 Shown is a schematic structural view of the third embodiment of the burner of the present invention. On the basis of the first embodiment, the burner adds the structure of the mixing device. The burner in this embodiment is also provided with a mixing aid piece 312 in the gas mixing pipe 302 as a mixing aid device for guiding the mixed gas to form a turbulent flow. The shape of the mixing aid sheet 312 and the setting position in the gas mixing tube 302 can be in various ways. It is preferable to set the sheet-like mixing aiding chip 312 parallel to the cross section of the gas mixing tube 302, and align the outer edge contour with the gas mixing tube 302. The mixing-aiding sheet 312 whose cross-sectional inner profile is adapted is blocked in the air-mixing pipe 302, and a notch is provided on the edge of the mixing-aiding sheet 312, such as Figure 7shown. A kind of preferred arrangement mode is: the longer section in the middle part of gas mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com