Storage unit of resistance storage and manufacture method thereof

A technology of resistive memory and storage unit, applied in static memory, read-only memory, digital memory information, etc., can solve problems such as the influence of RRAM reliability, and achieve the effect of improving resistance conversion performance and reducing oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

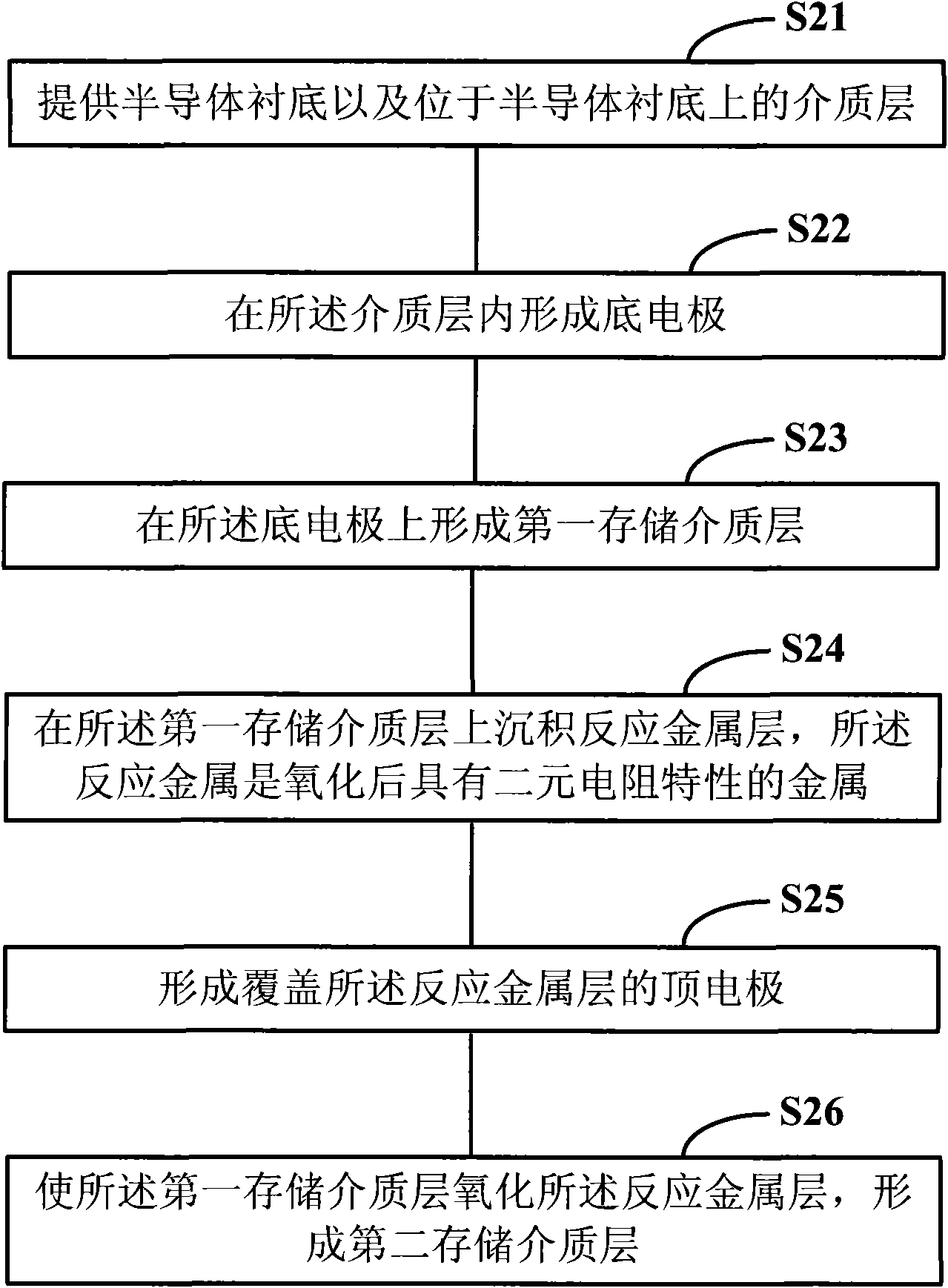

[0031] Please refer to the attached figure 2 , the manufacturing method of the storage unit of the resistive memory of the present embodiment, comprising:

[0032] Step S21, providing a semiconductor substrate and a dielectric layer on the semiconductor substrate;

[0033] Step S22, forming a bottom electrode in the dielectric layer;

[0034] Step S23, forming a first storage medium layer on the bottom electrode;

[0035] Step S24, depositing a reactive metal layer on the first storage medium layer, the reactive metal is a metal having binary resistance characteristics after oxidation;

[0036] Step S25, forming a top electrode covering the reactive metal layer;

[0037] Step S26, oxidizing the reactive metal layer on the first storage medium layer to form a second storage medium layer.

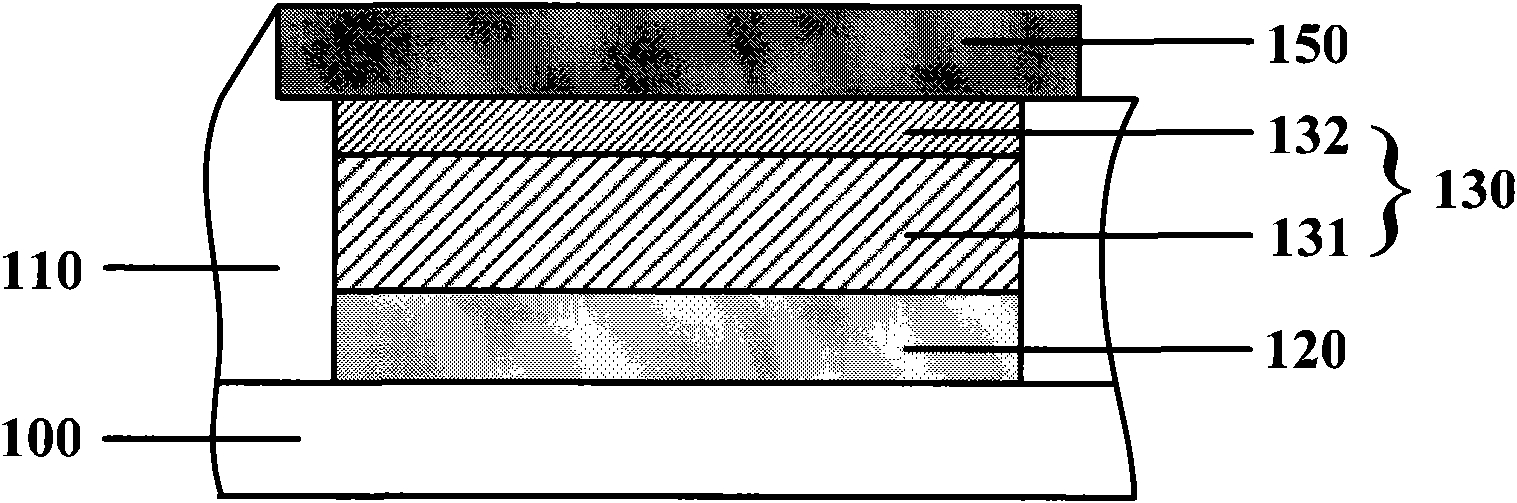

[0038] Please refer to the attached figure 2 and 4, step S21 , providing a semiconductor substrate 200 and a dielectric layer 210 on the semiconductor substrate 200 . The semiconduct...

Embodiment 2

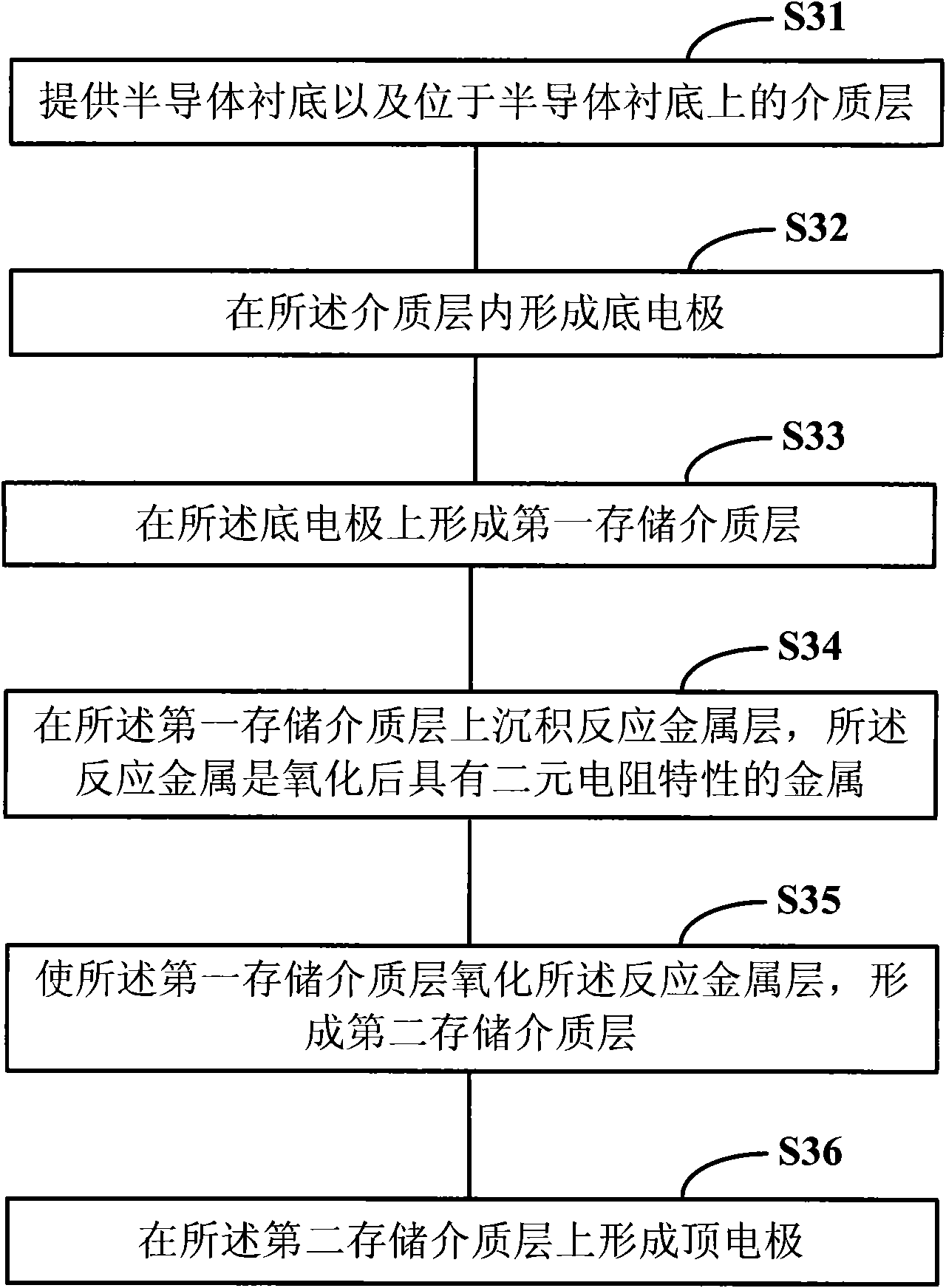

[0055] Please refer to the attached image 3 , the manufacturing method of the storage unit of the resistive memory of the present embodiment, comprising:

[0056] Step S31, providing a semiconductor substrate and a dielectric layer on the semiconductor substrate;

[0057] Step S32, forming a bottom electrode in the dielectric layer;

[0058] Step S33, forming a first storage medium layer on the bottom electrode;

[0059] Step S34, depositing a reactive metal layer on the first storage medium layer, the reactive metal is a metal having binary resistance characteristics after oxidation;

[0060] Step S35, making the first storage medium layer oxidize the reactive metal layer to form a second storage medium layer;

[0061] Step S36, forming a top electrode on the second storage medium layer.

[0062] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, a top electrode is first formed on the reactive metal layer, and then the reactive metal layer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com