Hydrothermal preparation method for potassium plumbite single crystal

A technology of potassium lead acid and single crystal, applied in the field of chemical engineering, can solve the problems of high energy consumption and uneven composition of potassium lead acid, and achieve the effect of reducing energy consumption and environmental pollution, and reducing the preparation process and production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

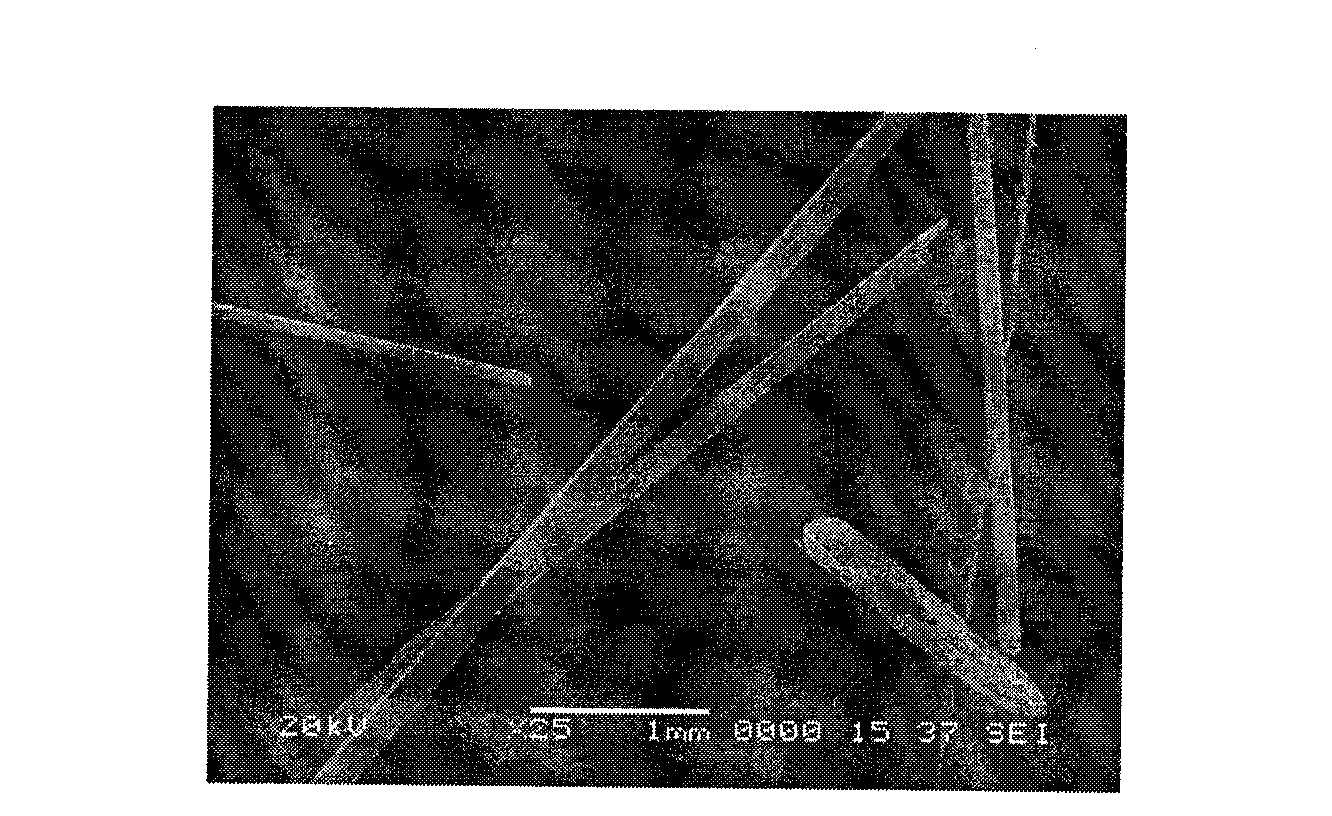

[0013] Put lead oxide (PbO) and potassium hydroxide (KOH) into the autoclave after weighing, the molar ratio of lead oxide and potassium hydroxide is 1, and add corresponding volume of deionized Water, adjust the amount of raw materials so that the concentration of potassium hydroxide is 2mol / L, stir slowly with a glass rod to dissolve potassium hydroxide; Raise the heating rate to 160 degrees Celsius, keep it warm for 24 hours, and then cool with the furnace; take out and open the autoclave, pour the reactants into a beaker, and use deionized water to filter and wash repeatedly until the washing liquid becomes neutral, and the obtained single crystal particles are placed Put it into the oven and bake at 60 degrees Celsius for 10 hours. The phase and crystal structure of potassium plumbate were detected by X-ray diffractometer; figure 1 The morphology and size of potassium plumbate were detected by scanning electron microscopy.

Embodiment 2

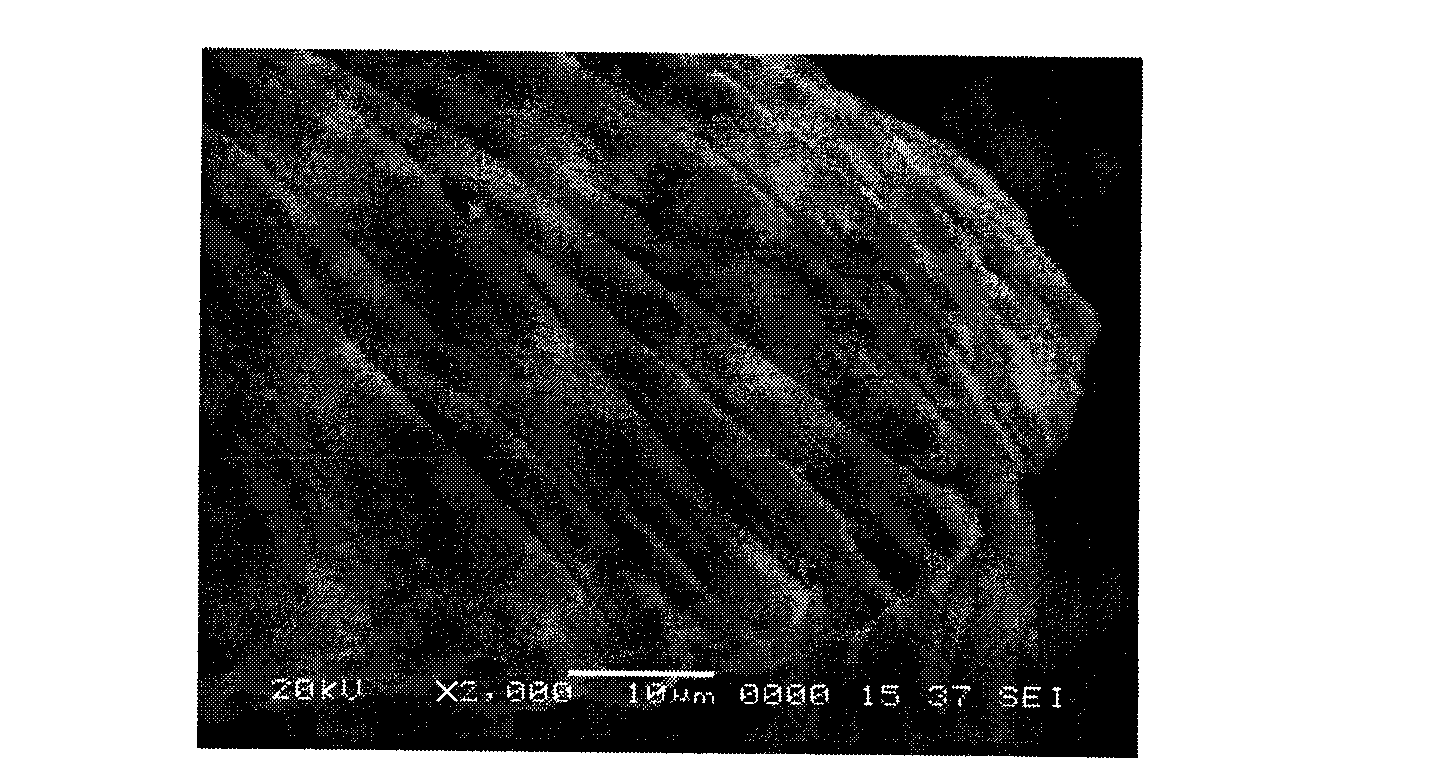

[0015] Put lead oxide (PbO) and potassium hydroxide (KOH) into the autoclave after weighing, the molar ratio of lead oxide and potassium hydroxide is 5, add the corresponding volume of deionized Water, adjust the amount of raw materials so that the concentration of potassium hydroxide is 4mol / L, stir slowly with a glass rod to dissolve potassium hydroxide; Raise the heating rate to 190 degrees Celsius, keep it warm for 16 hours, and then cool with the furnace; take out and open the autoclave, pour the reactants into a beaker, and use deionized water to filter and wash repeatedly until the washing liquid becomes neutral. Put it into the oven and bake at 60 degrees Celsius for 10 hours. The phase and crystal structure of potassium plumbate were detected by X-ray diffractometer; figure 2 The morphology of the growth tip of the potassium plumbate is examined using a scanning electron microscope.

Embodiment 3

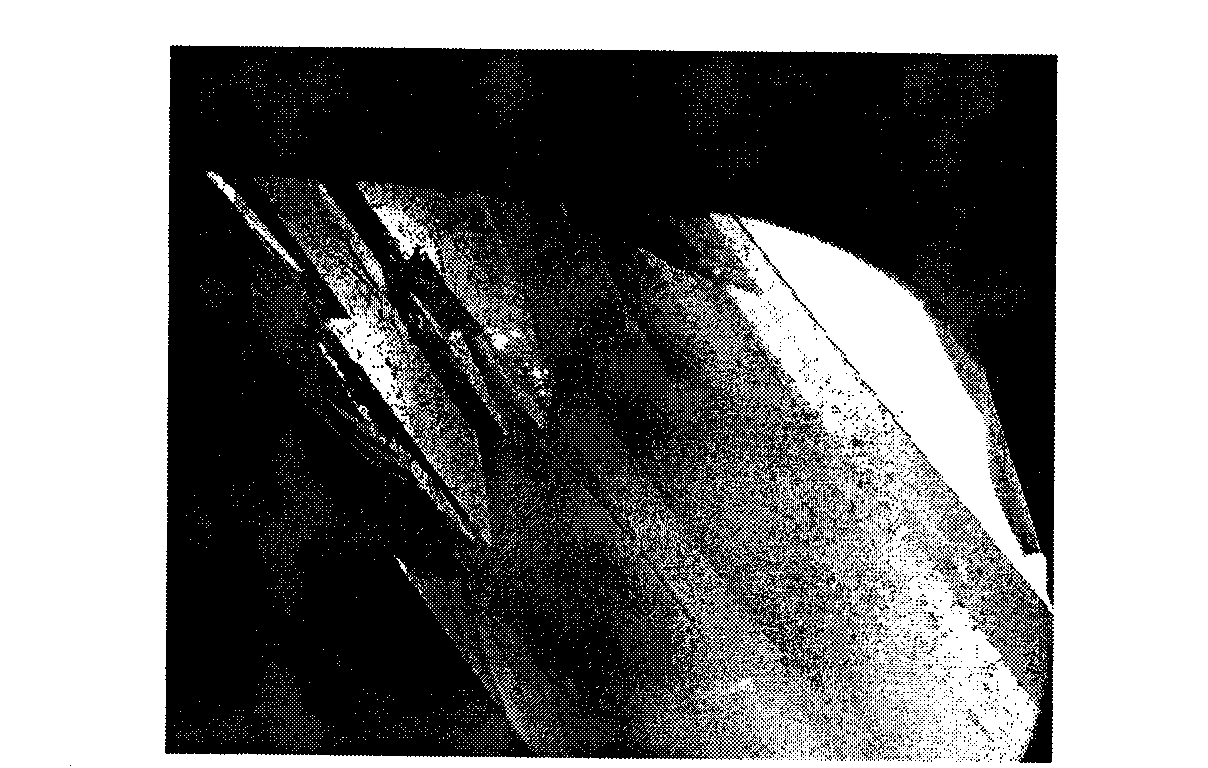

[0017] Put lead oxide (PbO) and potassium hydroxide (KOH) into the autoclave after weighing, the molar ratio of lead oxide and potassium hydroxide is 8, add the corresponding volume of deionized Water, adjust the amount of raw materials so that the concentration of potassium hydroxide is 7mol / L, stir slowly with a glass rod to dissolve potassium hydroxide; Raise the heating rate to 200 degrees Celsius, keep the temperature for 30 hours, and then cool with the furnace; take out and open the autoclave, pour the reactants into a beaker, and use deionized water to filter and wash repeatedly until the washing liquid becomes neutral. Put it into the oven and bake at 60 degrees Celsius for 10 hours. The phase and crystal structure of potassium plumbate were detected by X-ray diffractometer; image 3 The morphology of the potassium plumbate single crystals examined using a polarizing microscope is given.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com