Off-column vertical chemiluminescence detection device for capillary electrochromatography

A technology of chemiluminescence detection and capillary electrochromatography, which is applied in chemiluminescence/bioluminescence, measurement devices, and analysis by making materials undergo chemical reactions, can solve problems such as current instability, shortened service life, and column packing collapse. , to achieve the effects of reducing zone broadening, reducing eddy current diffusion, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

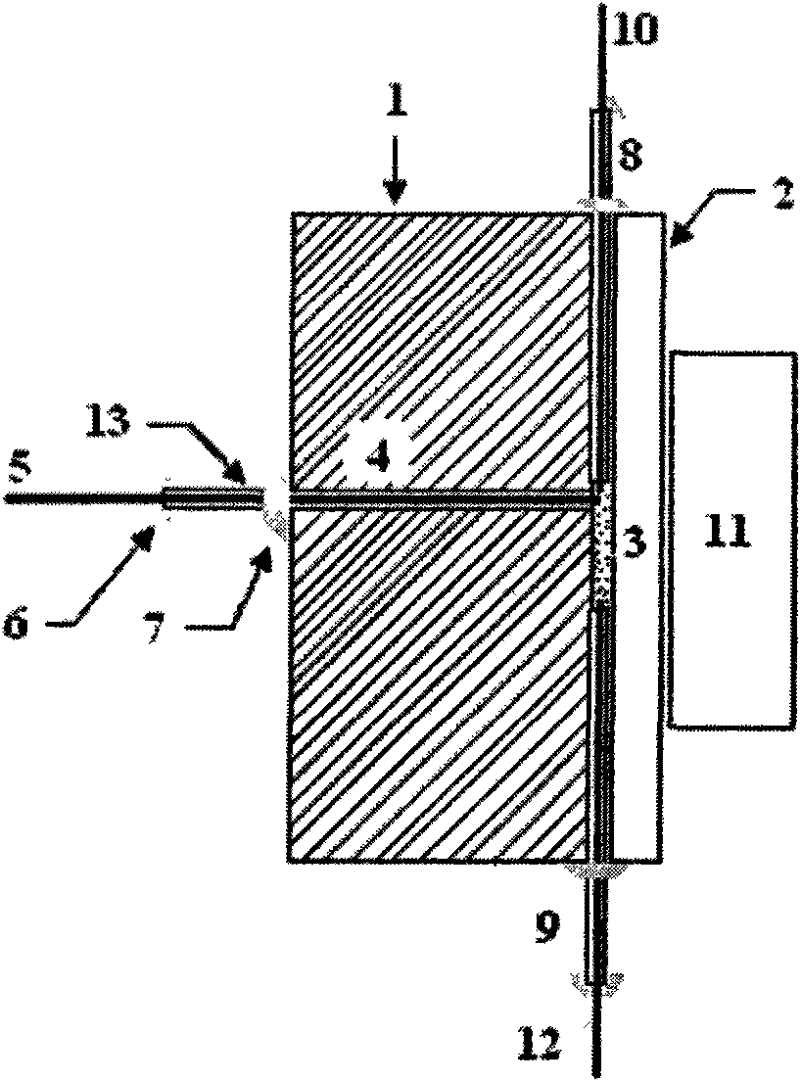

Method used

Image

Examples

Embodiment 1

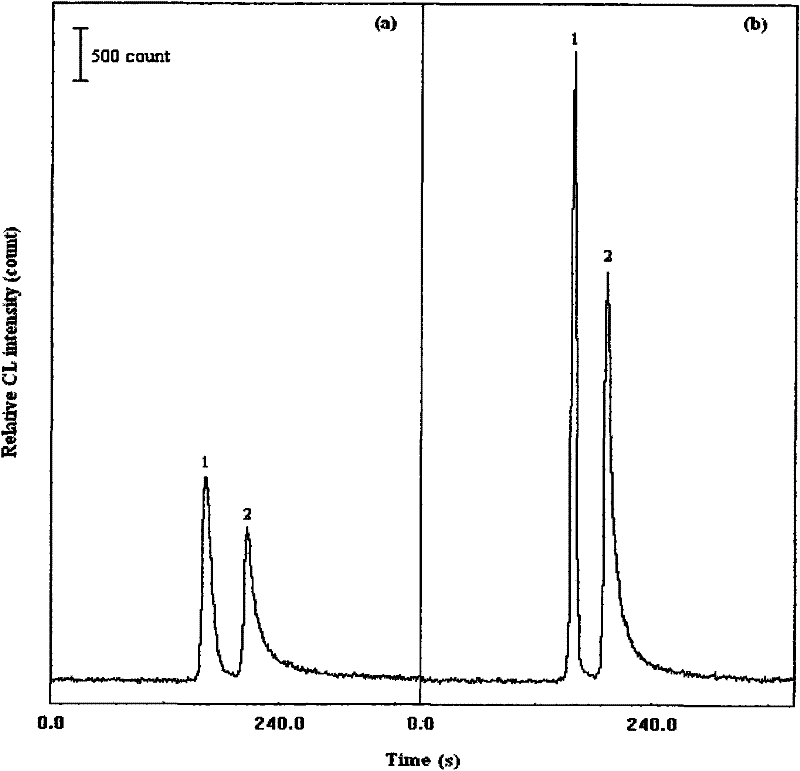

[0019] Using the pressurized capillary electrochromatographic off-column vertical chemiluminescence detection cell, the classic luminescent substances Luminol and ABEI were used as the detection objects to investigate the performance of the interface. The results are shown in figure 2 . The detection limit of Luminol and ABEI by off-column coaxial flow interface is 6.0×10 -8 mol / L and 8.0×10 -8 mol / L, the detection limit obtained from the vertical junction of the column is 2.0×10 -9 mol / L and 5.0×10 -9 mol / L, the detection sensitivity is significantly higher than that of the off-column coaxial flow interface, and a lower concentration detection limit is achieved. The experimental conditions are: polymeric monolithic column (100μm i.d.×375μm o.d.×30cm); the mobile phase is acetonitrile / borate=10 / 90 (%v / vpH8.0; 10mmol / L); the flow rate is 0.01mL / min; the column Post-luminescent reagent is K 3 Fe(CN) 6 =0.25mmol / L NaOH=1.0mol / L; the post-column luminescent reagent flow rat...

Embodiment 2

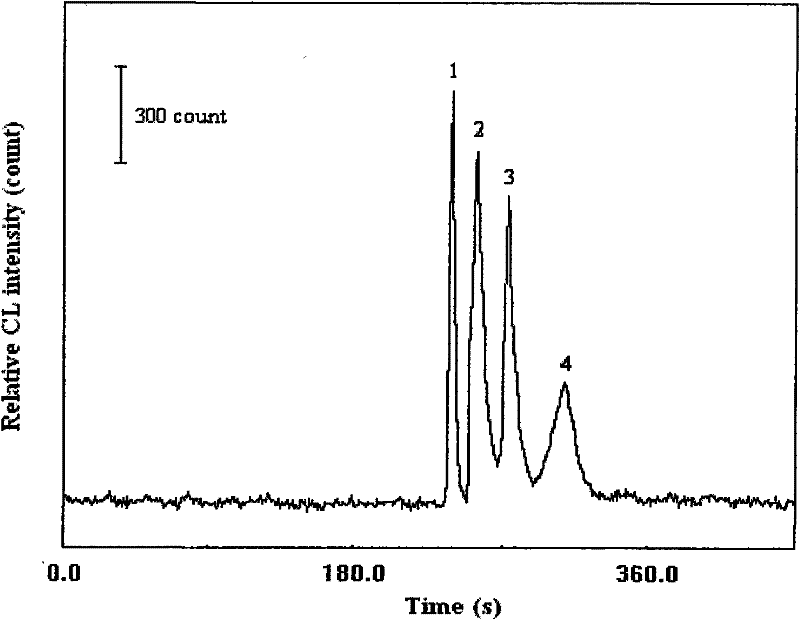

[0021] Using pressurized capillary electrochromatography vertical off-column chemiluminescence detection cell to separate and detect derivatized phenoxycarboxylic acid herbicides, the results are shown in image 3 : The linear range of MCPP, 2-PPA, 2,3-CPPA and 2,4-D reaches 2-3 orders of magnitude, and the detection limit is 2×10-9mol / L, 2×10-9mol / L, 3× 10-9mol / L and 2×10-8mol / L. The experimental conditions are: polymeric monolithic column (100μm i.d.×375μm o.d.×30cm); the mobile phase is acetonitrile / borate=25 / 75 (%v / v; pH6.8; 20mmol / L); the flow rate is 0.01mL / min The luminescent reagent behind the column is K3Fe(CN)6=0.1mmol / L NaOH=1.8mol / L; the flow rate of the luminescent reagent behind the column is 0.5mL / h; the separation voltage is 5kV; the chromatographic peak is (1) MCPP, (2) 2-PPA, (3) 2,3-CPPA, (4) 2,4-D (all 4.0×10-7 mol / L).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com