Full-automatic high speed four-shaft two-operating positions rotary welding device

A welding equipment and dual-station technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of low production efficiency, inappropriate application, limited application scope, etc., to achieve high production efficiency, guarantee Correctness, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

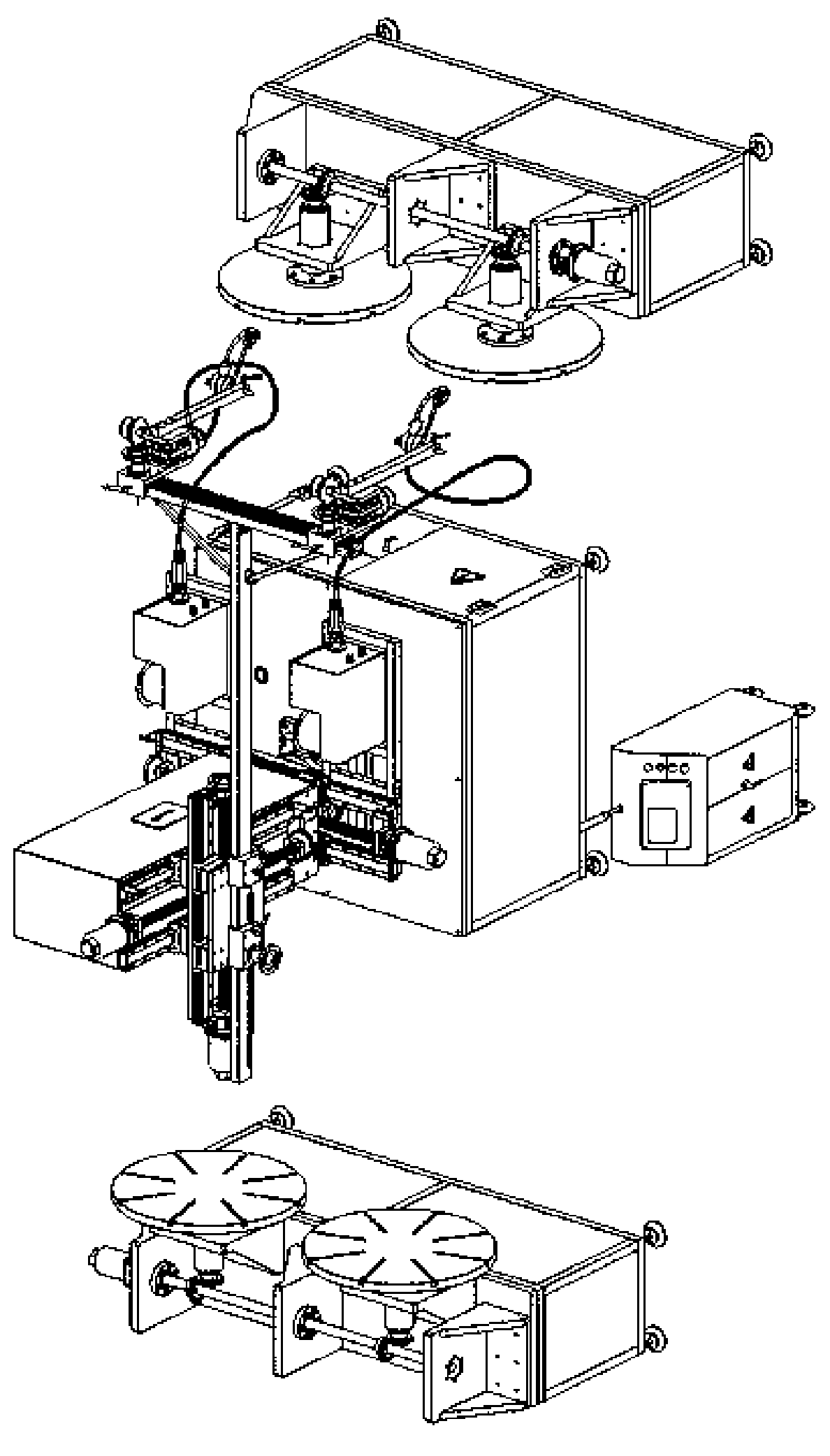

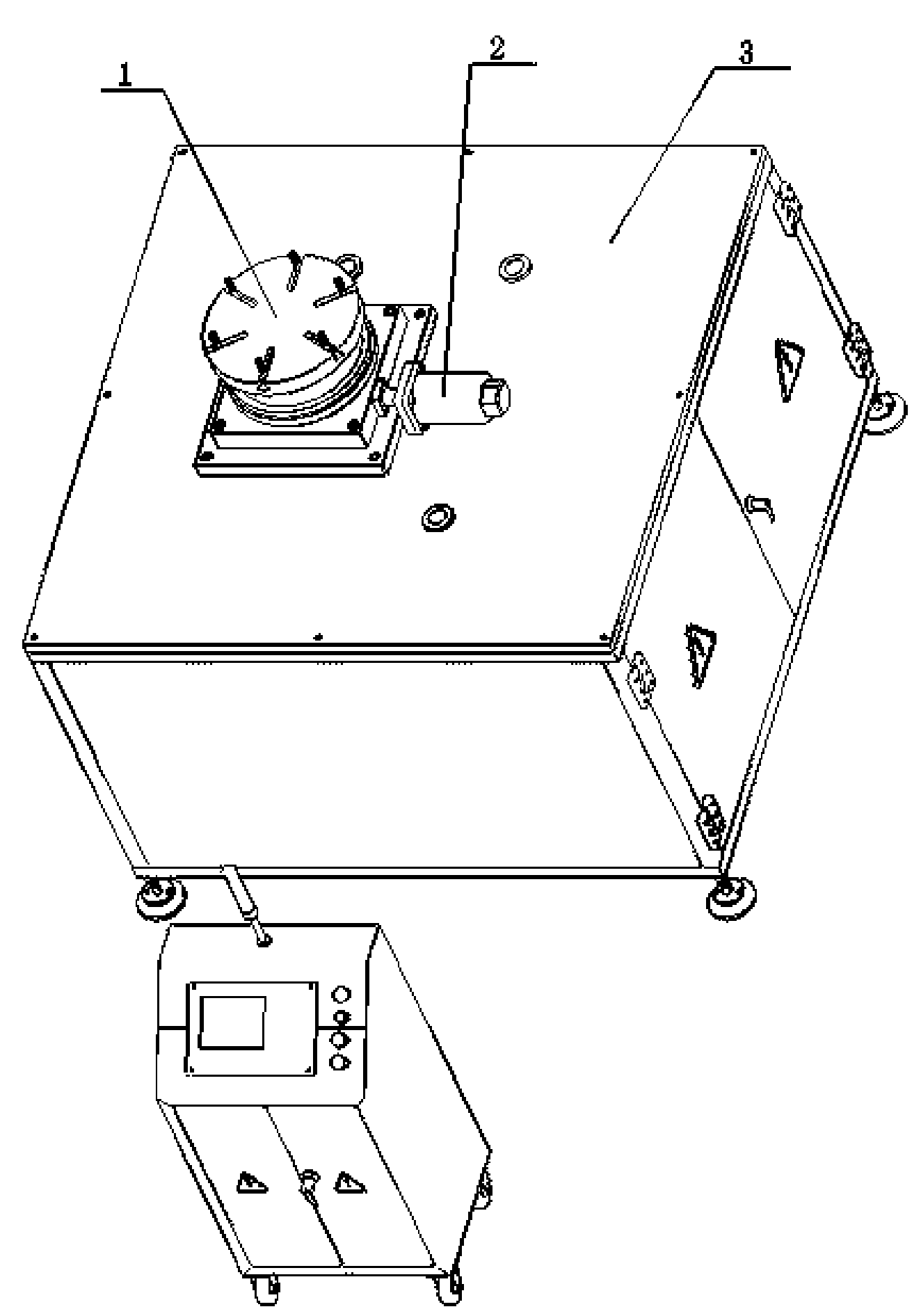

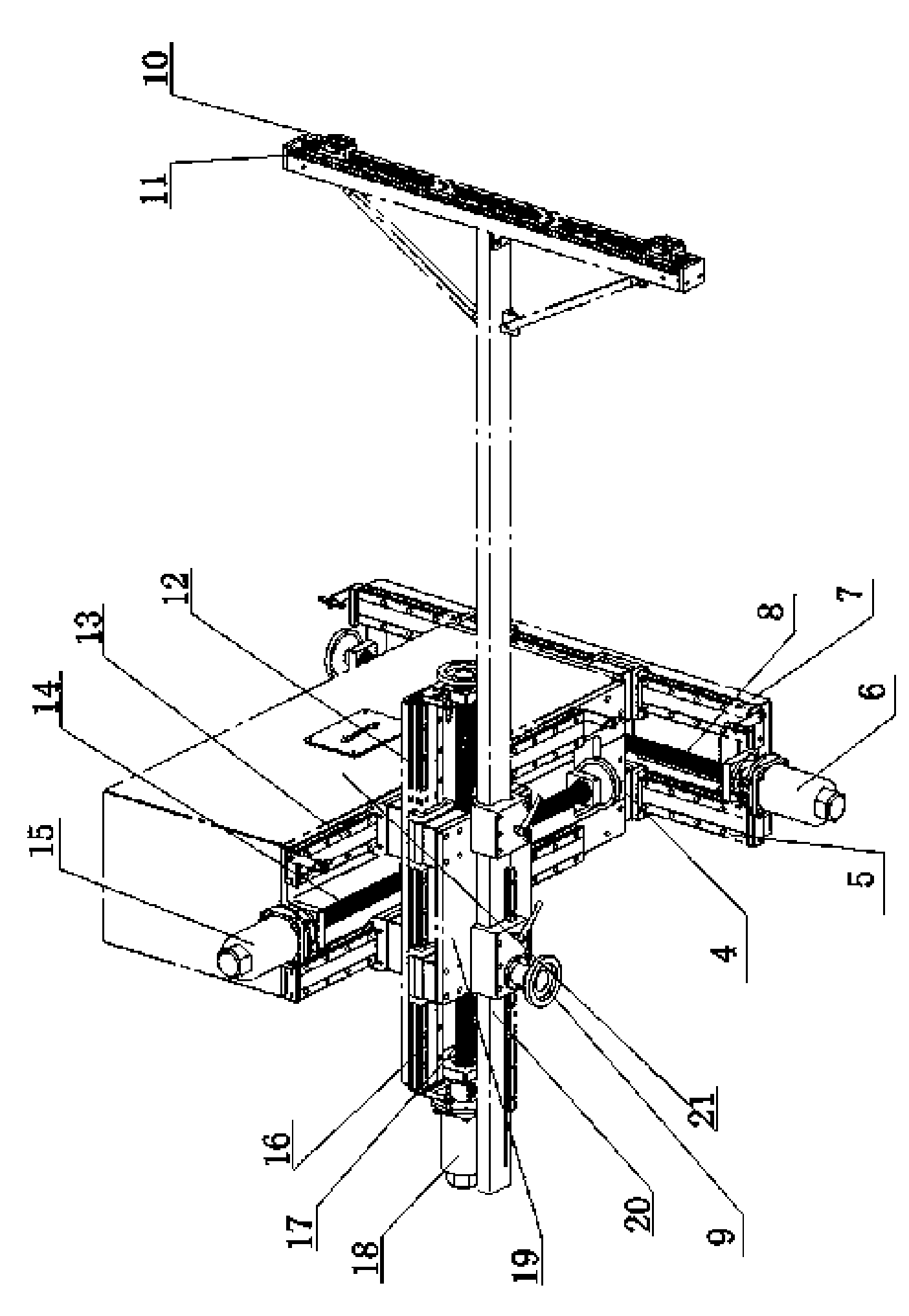

[0021] The present invention includes a rotary table 1, a servo motor 2, a frame 3, a bottom plate 4, a precision rolling guide rail pair 5, a servo motor 6, a Y-axis coordinate system bottom plate 7, a ball screw pair 8, a gear 9, and a precision rolling guide rail pair 10. Rack 11, Z coordinate system bottom plate 12, precision rolling guide pair 13, ball screw pair 14, servo motor 15, precision rolling guide pair 16, ball screw pair 17, servo motor 18, X-axis coordinate system bottom plate 19 , frame 21 of beam 20, Z-axis coordinate system, stepper motor 22, bearing 23, gear 24, stepper motor 25, ball screw pair 26, base plate 27, base plate 28, ball screw pair 29, welding gun adjustment Device assembly 30, vertical cube 31, bracket 32, welding torch 33, automatic seam tracking device 34, double station positioner 35, tooling fixed plate 36, frame 37, synchronous drive bevel gear pair 38, servo motor 39, Bolt 40.

[0022] There is a three-coordinate system of X, y, and z o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com