Method for preparing ethanol by adopting yam materials

A potato and raw material technology, which is applied in the field of ethanol preparation, can solve the problems of waste water not meeting environmental requirements, low utilization rate of equipment, and high pressure of waste water treatment, so as to achieve less water consumption, high utilization rate of equipment, The effect of less energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

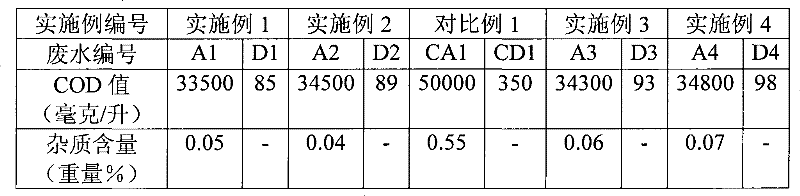

Examples

Embodiment 1

[0059] This example is used to illustrate the method for preparing ethanol using cassava raw material of the present invention.

[0060] (1) Crushing of cassava raw materials

[0061] This 95 kilograms of fresh cassava raw materials (water content 65% by weight) are washed and cut into discs of about 1 cm, and then the cassava chips are pulverized using the SFSP series hammer mill, and the pulverized method comprises first 60 One kilogram of cassava was crushed once for 20 minutes to obtain 60 kilograms of the primary crushed product with an average particle diameter of 4.5 mm, and then 60 kilograms of the primary crushed product of 10% by weight was mixed with the remaining 35 kilograms of fresh cassava raw materials that had not been crushed once again Pulverize 15 minutes, obtain the primary pulverization product that average particle diameter is 3 millimeters, and above-mentioned all primary pulverization products carry out secondary pulverization 5 minutes, obtain 95 kilo...

Embodiment 2

[0079] This example is used to illustrate the method for preparing ethanol using cassava raw material of the present invention.

[0080] The fresh cassava raw material was pulverized according to the method of Example 1 to obtain 95 kg of pulverized product (the average particle diameter of the cassava raw material in the pulverized product was 2 mm). According to the high-efficiency liquid phase conditions described in step (1) of Example 1, it was measured and calculated that the 95 kg pulverized product contained 26.5 kg of starch. According to the conditions of Example 1, the remaining crushed product after the sampling test was enzymatically hydrolyzed, and the enzymolyzed product was fermented to obtain 13.91 kg of ethanol.

[0081] Take 100 grams of distilled ethanol and filter the remaining fermented mash with a Buchner funnel, transfer 20 milliliters of the filtrate to a dry 50 milliliter Erlenmeyer flask, let it stand for 5 hours, and collect the supernatant. The su...

Embodiment 3

[0099] This example is used to illustrate the method for preparing ethanol using cassava raw material of the present invention.

[0100] Prepare ethanol according to the method of Example 1, the difference is that the pulverizing method includes using SFSP series hammer mill to pulverize 30 kilograms of fresh cassava raw materials (water content 65% by weight) once for 12 minutes to obtain the average particle size Diameter is 30 kilograms of primary pulverization products of 5.5 millimeters, then 1.5 kilograms of this primary pulverization products of 5% by weight are mixed with the remaining 25 kilograms of fresh cassava raw materials that have not been pulverized and are pulverized again for 10 minutes to obtain an average particle diameter of 3 55 kilograms of the primary crushed product of mm, 2.75 kg of the primary crushed product of 5% by weight and the remaining 40 kg of cassava that have not been crushed were crushed for 15 minutes to obtain 95 kg of the primary crushe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com