Phosphoric diffusion technology for metallurgical-grade polysilicon solar cells

A solar cell and metallurgical grade technology, applied in the field of diffusion process, can solve problems such as unsatisfactory effect of solar cell composite improvement, and achieve the effects of better product uniformity, improved minority carrier life, and reduced generation of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

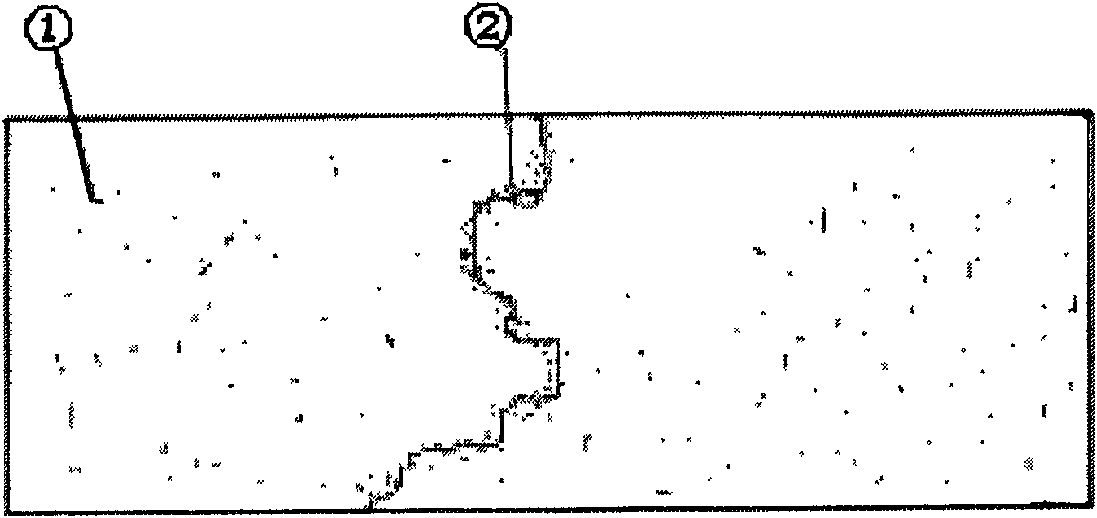

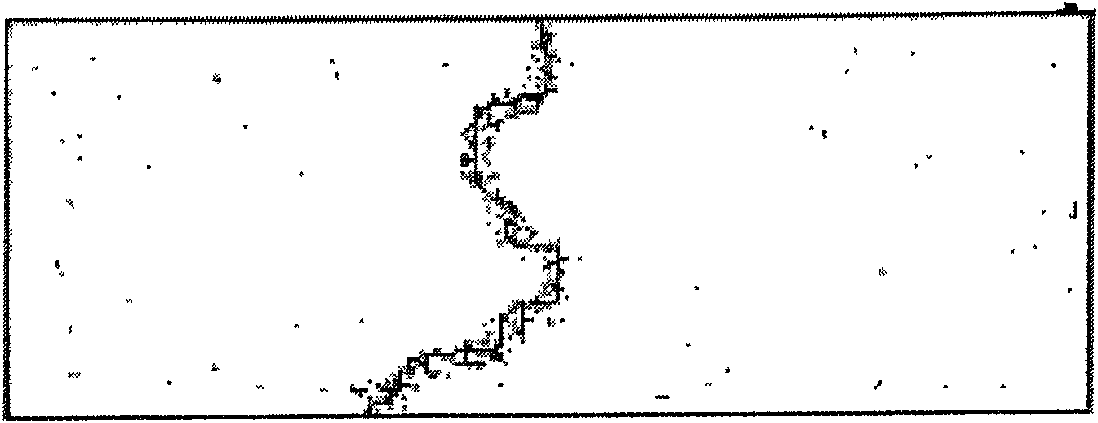

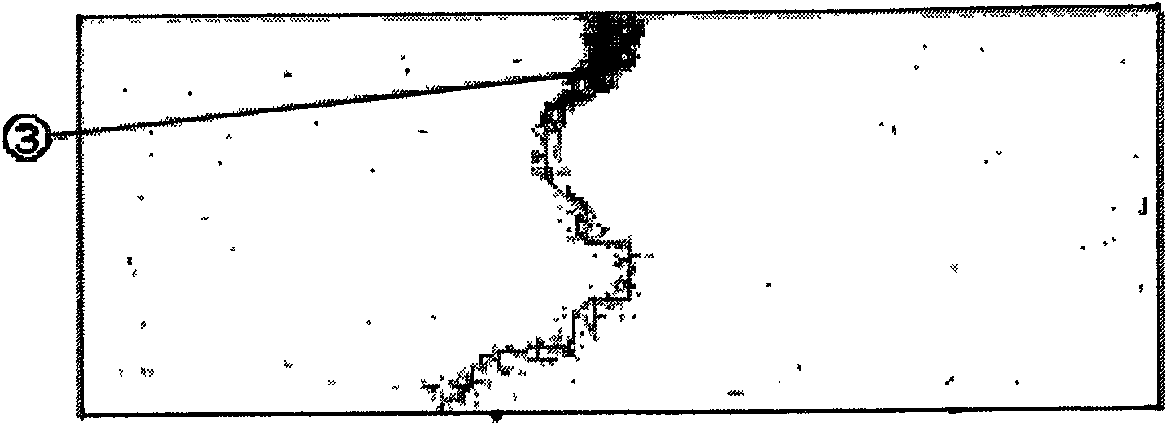

Image

Examples

Embodiment Construction

[0019] A phosphorus diffusion process for metallurgical-grade polycrystalline silicon solar cells, first of all, a high-temperature grain boundary impurity absorption step, using high temperature to release some metal impurity atoms at the original precipitation, and at the same time diffuse and move to the grain boundary defect for deposition. That is, the grain boundary is used as the gettering point to complete the gettering at the grain boundary, and a "clean area" is formed near the grain boundary.

[0020] Followed by medium and low temperature phosphorus deposition step. Use medium and low temperature phosphorus diffusion, 20°C-40°C lower than the normal diffusion temperature, short time, 5min-15min less than the normal diffusion deposition time, to carry out light phosphorus diffusion deposition, this step completes the surface low-concentration phosphorus deposition, which is the next step length Time for high temperature drive in preparation.

[0021] This is follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com