Arrestor

A technology of lightning arrester and insulating sleeve, which is applied in the field of lightning arrester, can solve the problems of damage to lightning arrester components, difficulty in electric field concentration, etc., and achieve the effects of preventing dielectric breakdown, reducing weight, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

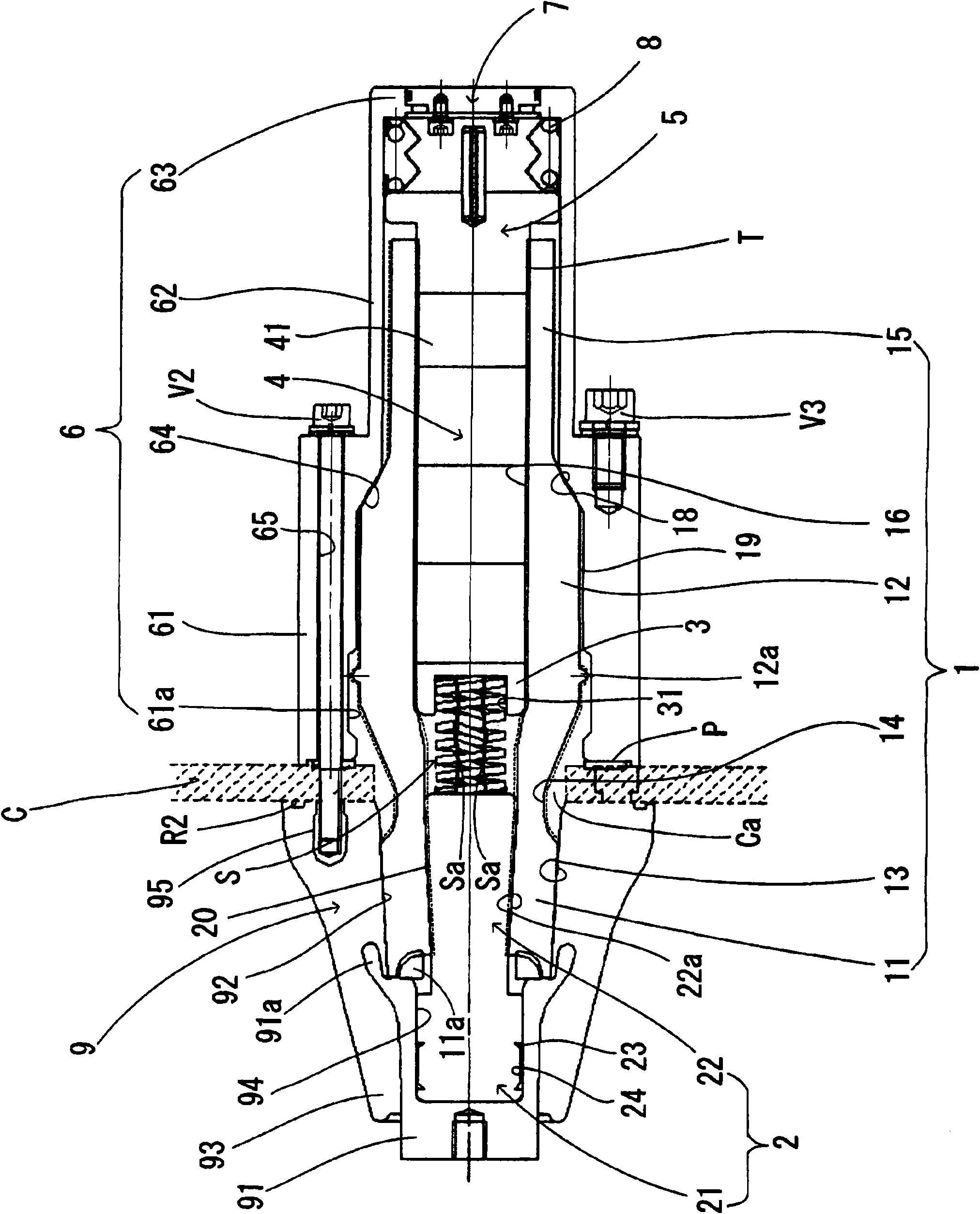

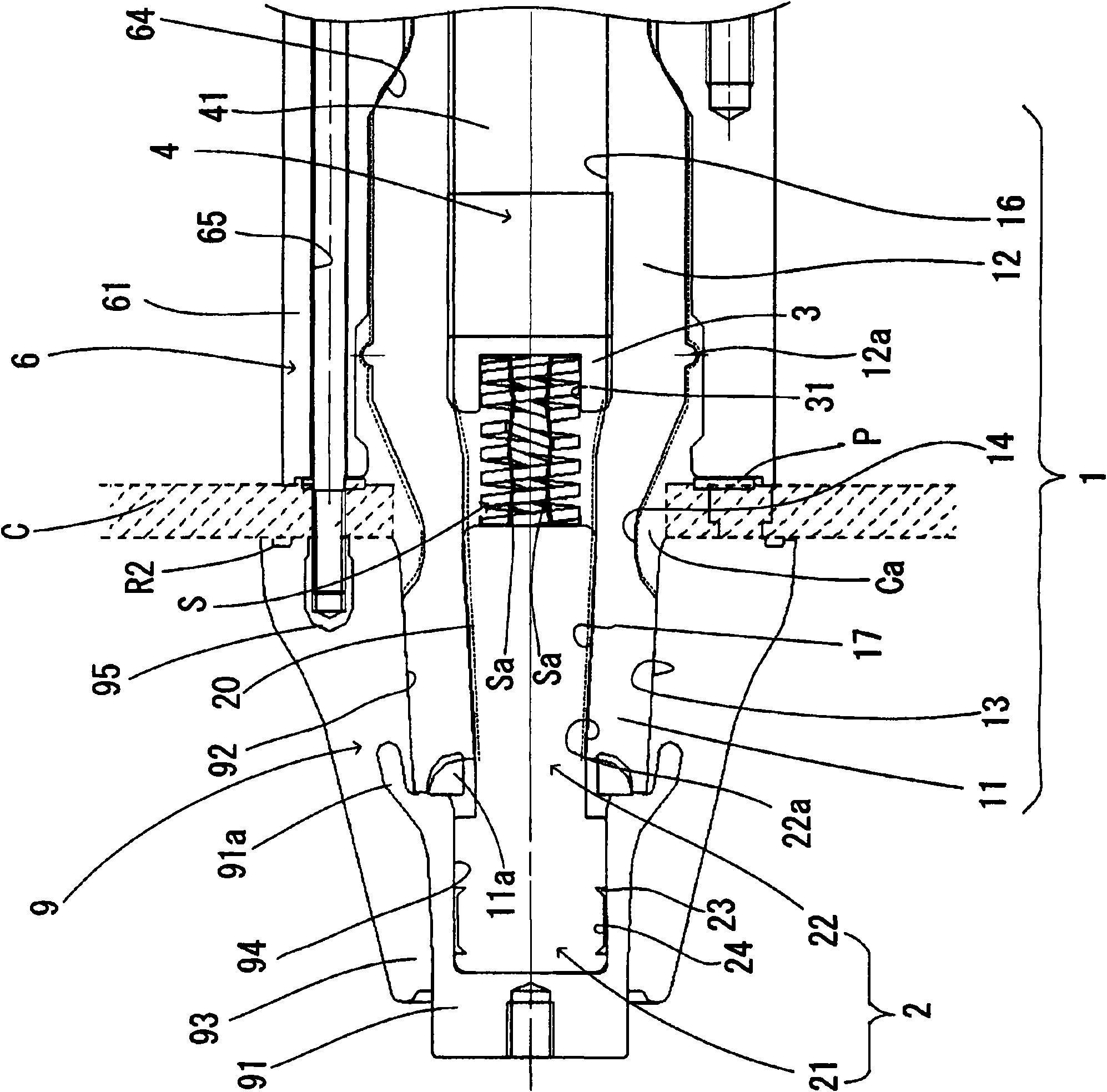

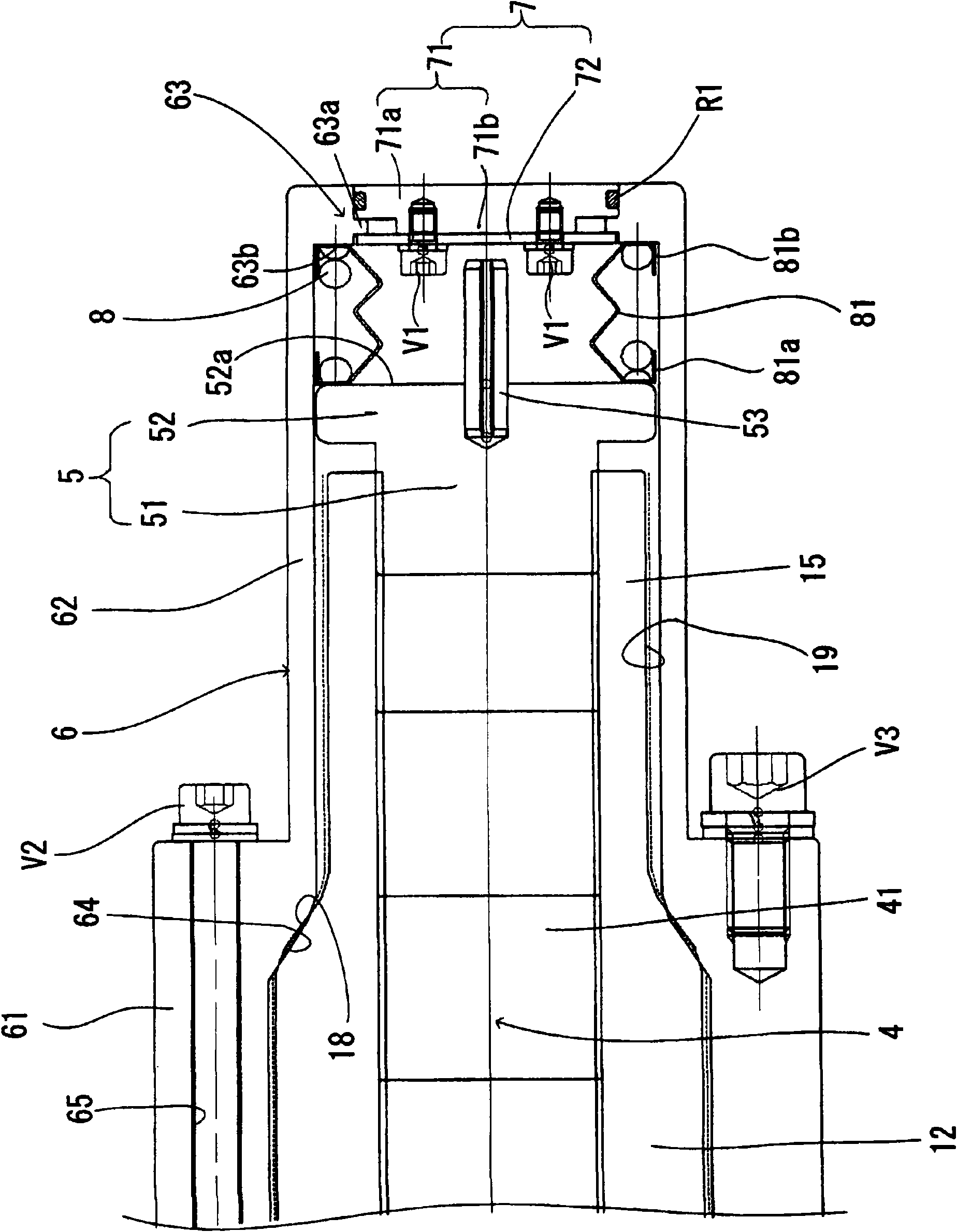

[0099] figure 1 is a partial sectional view showing an example of a 22kV class arrester in the first embodiment of the present invention, figure 2 Yes figure 1 An enlarged partial cross-sectional view of the front end portion of the arrester shown in , while image 3 Yes figure 1 An enlarged partial cross-sectional view of the rear end portion of the arrester shown in .

[0100] exist figure 1 Among them, the 22kV class arrester of the present invention is provided with an insulating sleeve 1, which includes a rubber-like elastic body such as silicon rubber, and a conductor 2 including, for example, an aluminum rod is arranged at the front end portion (high voltage side) of the aforementioned insulating sleeve 1 )11 center. In addition, a spindle-shaped larger-diameter portion 12 is arranged at the outer periphery of an almost central portion of the insulating sleeve 1, and a tapered outer surface 13 whose diameter gradually and smoothly becomes larger toward the rea...

Embodiment 2

[0131] Figure 5is a partial sectional view showing an example of a 22 kV class arrester in the second embodiment of the present invention. Furthermore, in this figure, the same reference numerals indicate figure 1 , and omit their detailed descriptions. In addition, in Figure 5 , for ease of understanding, omits the figure 1 The shielding layer 19 on the insulating sleeve 1 is shown in FIG.

[0132] In this example, if Figure 5 As shown in , by making the outer peripheral surface of the insulating sleeve 1 (especially the outer peripheral surface of the larger diameter portion 12 of the insulating sleeve 1, which has a higher electric field) and the inner surface of the corresponding position of the metal shell 6 The peripheral surfaces are in contact, which is configured such that no diameter difference occurs between the inner peripheral surface of the metal case 6 and the outer peripheral surface of the insulating sleeve 1 .

[0133] Here, the following describes...

Embodiment 3

[0139] Figure 7 is a partial sectional view showing an example of a 22 kV class arrester in the third embodiment of the present invention. Furthermore, in this figure, the same reference numerals indicate figure 1 , and omit their detailed descriptions. In addition, in Figure 7 , for ease of understanding, omits the figure 1 The shielding layer 19 on the insulating sleeve 1 is shown in FIG.

[0140] In this example, if Figure 7 As shown in , in the outer circumference of the insulating sleeve 1, especially in the outer circumference of the larger diameter portion 12 of the insulating sleeve 1 (the larger diameter portion 12 of the insulating sleeve 1 has a higher electric field), there is provided for The gap G (refer to Image 6 )'s inclusion F.

[0141] As such inclusions F, there may be, for example: a longitudinally arranged layer of a rubber band including, for example, butyl rubber (the longitudinally arranged layer is longitudinally arranged at the outer per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com