Reciprocating hydraulic bottom mud scraper

A mud scraper, reciprocating technology, applied in chemical instruments and methods, separation methods, precipitation separation, etc., can solve the problems of indurability, difficult maintenance, etc., and achieve long service life, easy maintenance, convenient and quick installation and adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

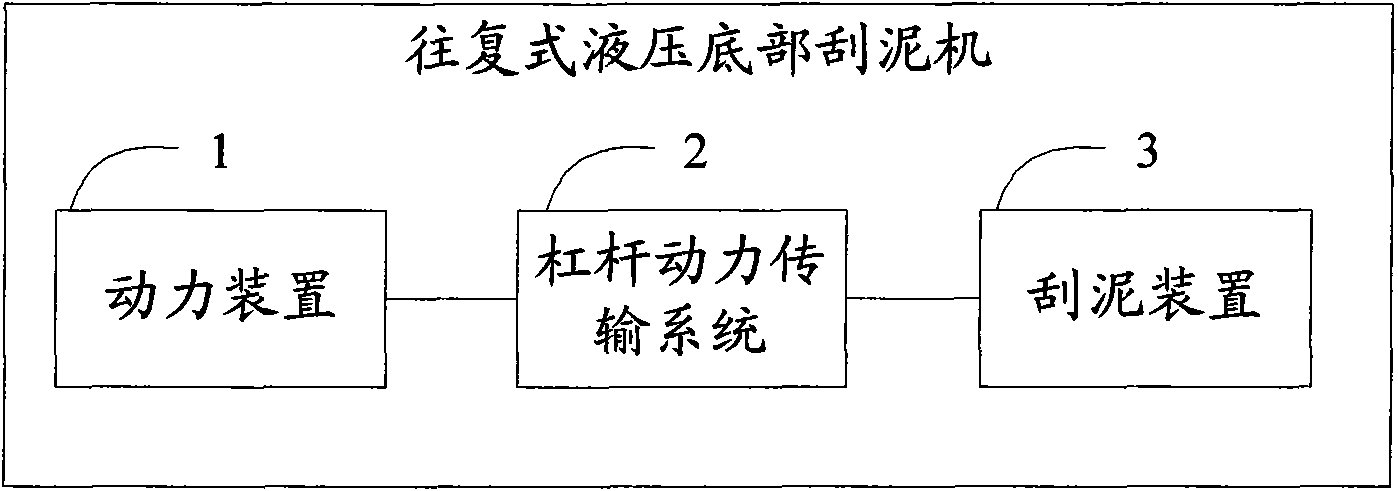

[0021] Embodiment 1, see figure 1 As shown, it includes: a power device 1 , a lever power transmission system 2 and a mud scraping device 3 connected in sequence.

[0022] Among them, the power device 1 is used to output power, which can be a cylinder device or a motor device. In practical applications, the sedimentation tank with a size of more than 250 square meters is driven by hydraulic pressure, and the sedimentation tank with a size of less than 250 square meters is directly driven by an electric motor.

[0023] The lever power transmission system 2 is used to transmit the power output by the power device 1 to the mud scraping device 3 .

[0024] The mud scraping device 3 is pulled by the lever power transmission system 2, and reciprocates at the bottom of the pool body to remove sludge.

Embodiment 2

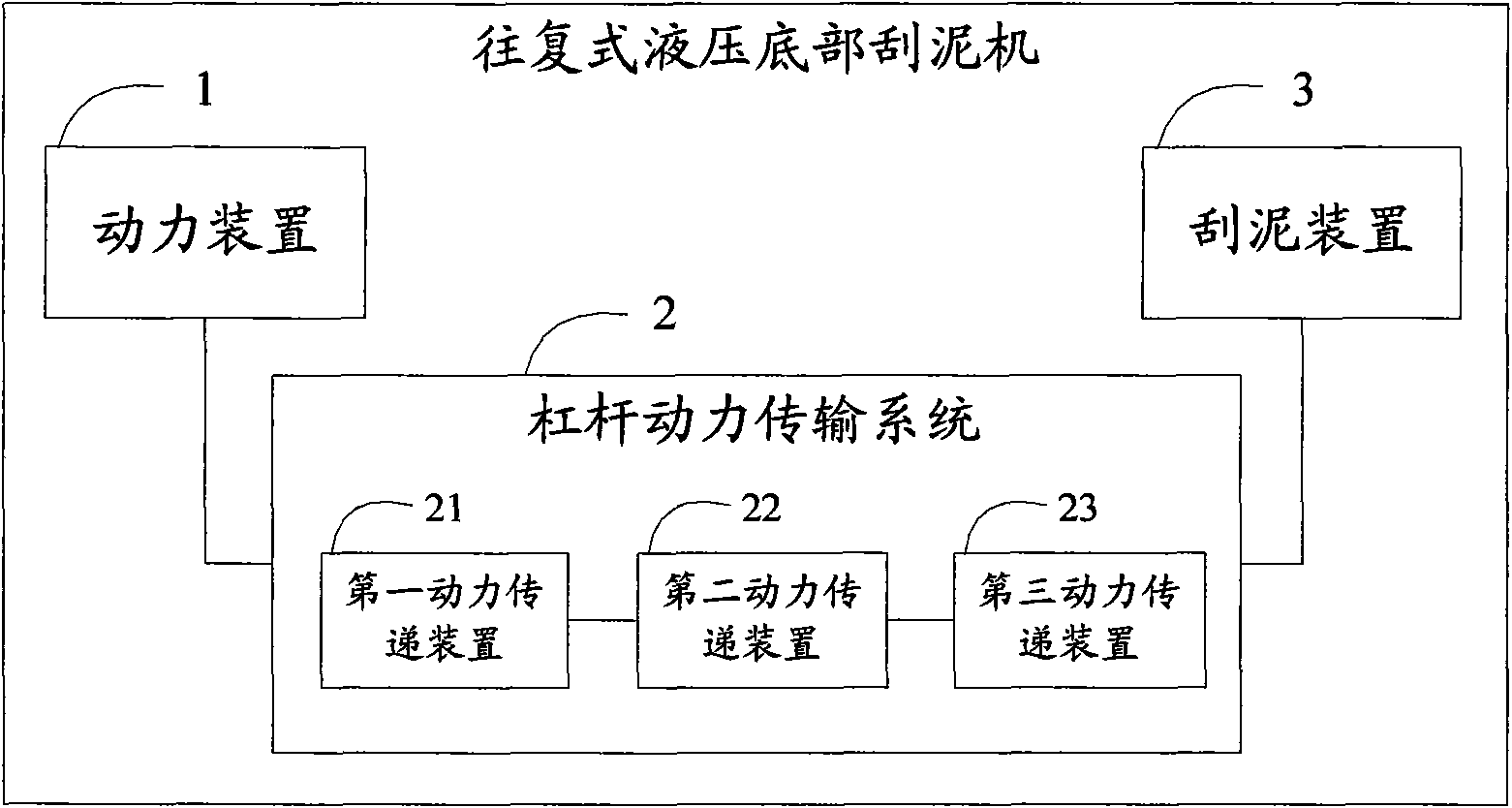

[0025] Embodiment 2, this embodiment further refines the lever power transmission system 2 in Embodiment 1, see figure 2 As shown, it includes: a power device 1 , a lever power transmission system 2 and a mud scraping device 3 connected in sequence.

[0026] Among them, the power device 1 is used to output power, which can be a cylinder device or a motor device. In practical applications, the sedimentation tank with a size of more than 250 square meters is driven by hydraulic pressure, and the sedimentation tank with a size of less than 250 square meters is directly driven by an electric motor.

[0027] The lever power transmission system 2 specifically includes: a first power transmission device 21 for transmitting the power output by the power device 1; a second power transmission device 22 for turning the direction of the power transmitted by the first power transmission device 21, turning The final power direction is generally consistent with the moving direction of the m...

Embodiment 3

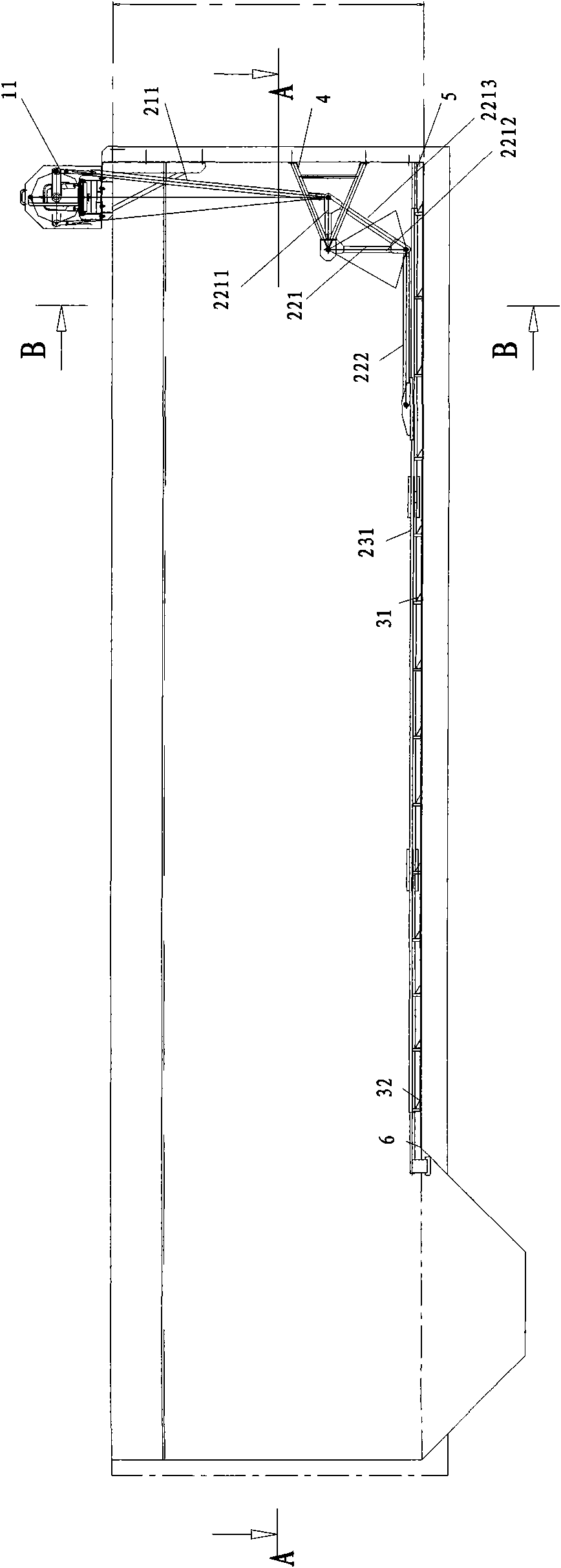

[0029] Embodiment 3. This embodiment further refines the first, second, and third power transmission devices and mud scraping devices in the lever power transmission system 2 in embodiment 2. See image 3 , 4 , 5, 6, 7, 8, including: cylinder device 11, first push-pull rod 211, angle arm support frame 4, angle arm 221, link arm 222, second push-pull rod 231, guide rod 5, scraper 31, Scraper 32, bottom surface slide rail 6. It is mainly powered by the cylinder device 11, the first power transmission device 21 is made by the first push-pull rod 211, the second power transmission device 22 is made by the angle arm 221 and the link arm 222, and the third power transmission device is made by the second push-pull rod 231 The device 23, the scraper 31 and the scraper 32 are the mud scraping device 3 for the final mud scraping action. Wherein the corner arm support frame 4 is fixed on the pool wall, plays the role of fixing the corner arm 221, one end of the guide rod 5 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com