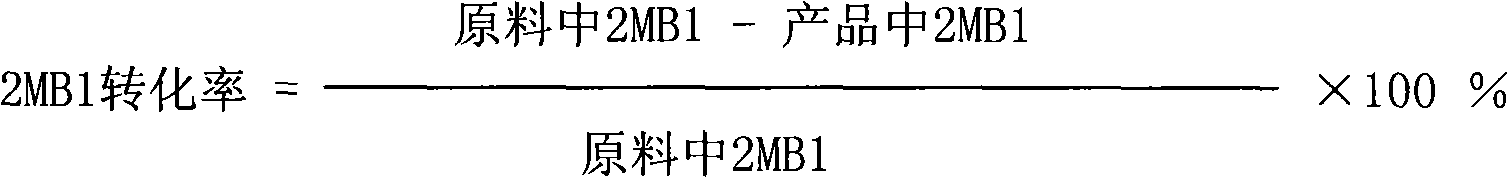

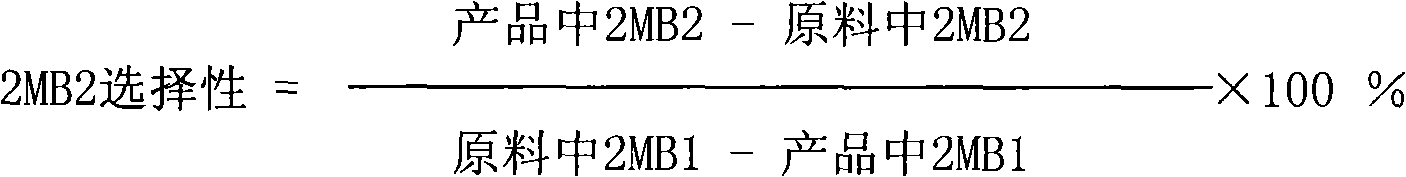

Method for isomerizing 2-methyl-1-butylene into 2-methyl-2-butylene

A technology of butene and methyl, which is applied in the field of increasing the content of 2-methyl-2-butene in crude isopentene, can solve the problems of product yield reduction, abnormal fluctuation of catalyst bed temperature, and increase of energy consumption. Achieve the effects of improving conversion rate and selectivity, eliminating abnormal fluctuations in bed temperature, and reducing the content of dimers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

[0017] 1. Raw materials for isomerization reaction

[0018] The raw material used in Examples 1-12 is crude isopentene, and the C5 fraction produced by steam cracking of naphtha to produce ethylene is reacted with methanol to obtain methyl tert-amyl ether, which is obtained after high-temperature cracking and water elution to remove methanol . The composition of crude isopentene is shown in Table 1.

[0019] Table 1.

[0020] 2MB2

(wt%)

2MB1

(wt%)

2MB2 / 2MB1

(mass ratio)

TAME

(wt%)

(wt%)

Other carbon five and other impurities

74.18

25.04

2.96

0.57

0.04

margin

[0021] 2. Isomerization reaction

[0022] The isomerization reaction is carried out in a stainless steel tubular fixed-bed reactor with a size of φ25mm×1500mm. 40 grams of spherical sulfonic acid-based cation exchange resin catalysts with a particle size of 0.40-1.25 mm are loaded into the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com