Highly-abrasion-resistant butadiene-acrylonitrile-rubber vulcanized rubber and preparation method thereof

A technology of nitrile rubber and wear-resistant nitrile, which is applied in the field of polymer materials, can solve problems such as the inability to carry out large-scale popularization and application, low friction coefficient of nitrile rubber, limited impact resistance and wear resistance, etc., and achieve the reduction of friction coefficient, Effect of increasing wear resistance and improving elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

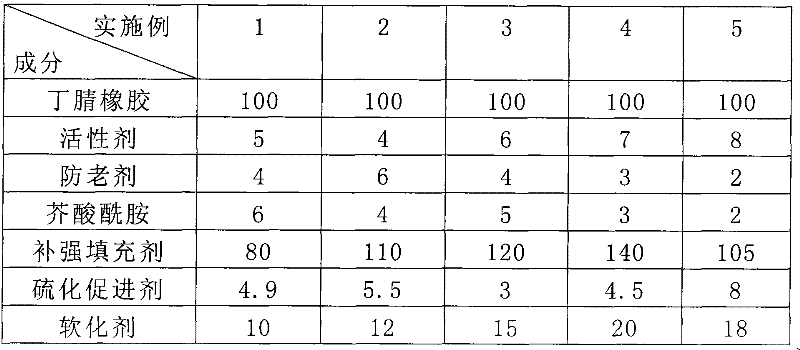

Embodiment 1

[0033]The active agent described in embodiment 1 is made up of zinc oxide: 4 parts and stearic acid: 1 part; Described anti-aging agent is made up of anti-aging agent RD: 2 parts and anti-aging agent MB: 2 parts; Described reinforcement The filler is made up of 40 parts of high wear-resistant carbon black and 40 parts of semi-reinforced carbon black; the vulcanization accelerator is composed of accelerator CBS: 2 parts, accelerator TMTD: 1.3 parts, accelerator TETD1.3 parts and sulfur: 0.3 parts; the softener is dinonyl phthalate.

Embodiment 2

[0034] The active agent described in embodiment 2 is made up of zinc oxide: 3 parts and stearic acid: 1 part; Described anti-aging agent is made up of anti-aging agent RD: 2 parts, anti-aging agent MB: 1 part and anti-aging agent D: 3 parts Composition; The described reinforcing filler is made up of 20 parts of high wear-resistant carbon black, 60 parts of fast extrusion carbon black and diatomite: 30 parts; The described vulcanization accelerator is made up of accelerator TETD: 2 parts, accelerator DM: 3 parts and 0.5 part of sulfur, the softener is dinonyl phthalate.

Embodiment 3

[0035] The active agent described in embodiment 3 is made up of zinc oxide: 5 parts and stearic acid: 1 part; Described anti-aging agent is made up of anti-aging agent BLE: 2 parts and anti-aging agent 4010NA: 2 parts; Described reinforcement The filler consists of calcium bicarbonate: 30 parts, diatomite: 30 parts and high wear-resistant carbon black 60 parts; the vulcanization accelerator consists of accelerator TMTD: 1 part and accelerator CBS: 1 part, sulfur 1 part Composition, described softening agent is dioctyl phthalate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com