Autoclaved fly ash semi-blind porous brick and preparation method thereof

A technology of fly ash and porous bricks, which is applied in the field of autoclaved fly ash semi-blind porous bricks and its preparation, can solve the problems of low compressive strength, high cost, and insufficient durability, and achieve improved compressive strength and durability Performance, low drying shrinkage, and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

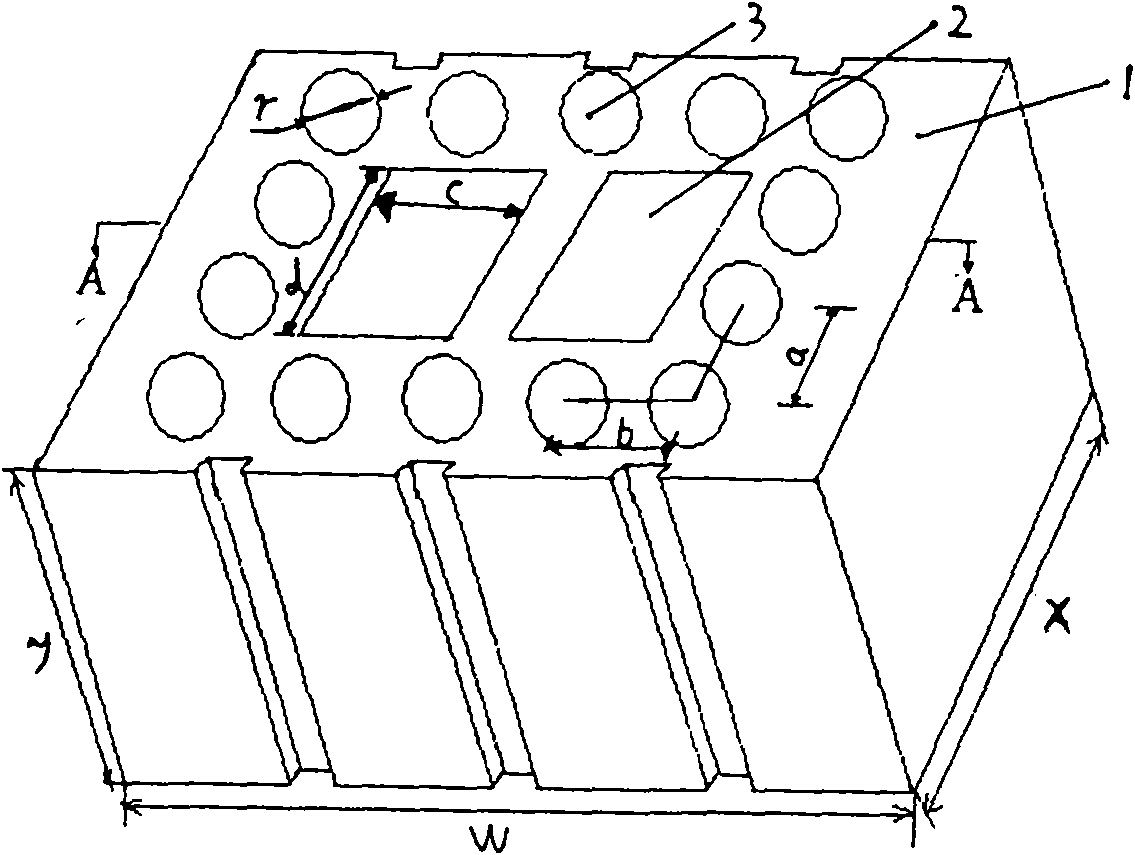

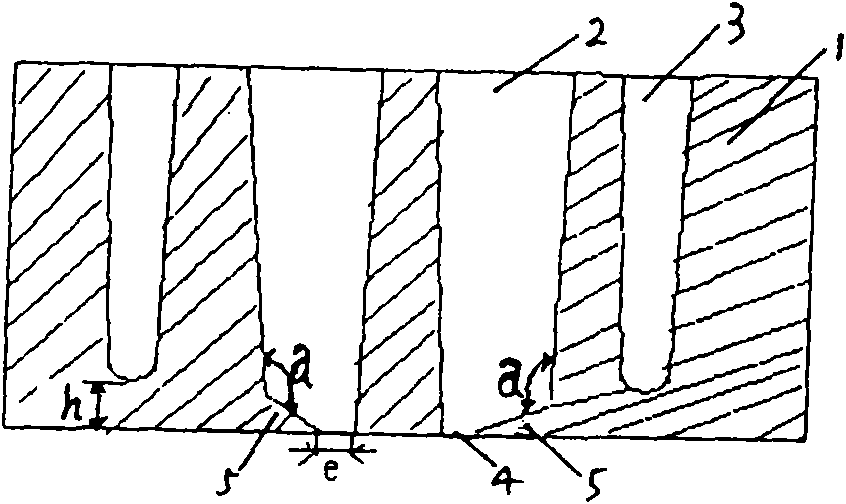

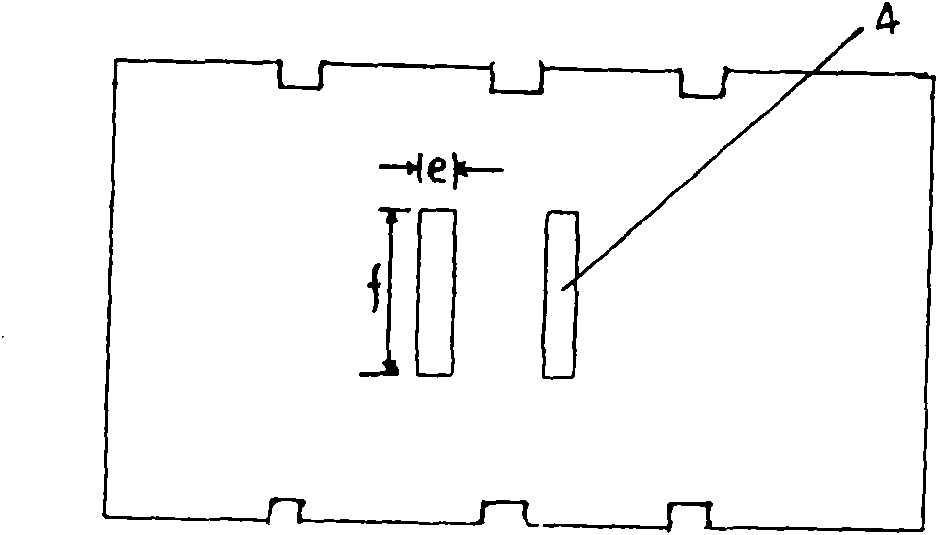

[0025] like figure 1 , figure 2 and image 3 As shown, the autoclaved fly ash semi-blind porous brick is provided with two square hollow holes 2 in the middle of the brick 1; several semi-blind circular holes 3 are arranged around the two square hollow holes 2; The length direction of the orifice 4 of the square hollow hole 2 at the bottom has a slope 5, the angle a between the slope 5 and the inner wall is 125°, and the distance h between the bottom of the semi-blind circular hole 3 and the bottom of the brick 1 is 10mm.

[0026] The specifications of the brick: the length w is 235-245mm, the width x is 185-195mm, and the height y is 110-120mm; the orifice specification of the square hollow hole on the front of the brick: the length d is 65-75mm, and the width c is 50 ~55mm; orifice specification of the square hollow hole at the bottom of the brick: the length f is 45~50mm, the width e is 5~10mm; the diameter r of the semi-blind circular hole is 28~32mm, the semi-blind arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com