Preparation method of modified phenolic resin binder for casting

A technology of phenolic resin and binder, which is applied in the field of preparation of modified phenolic resin binder for foundry, can solve the problems of high binder cost, poor reusability, poor performance, etc., and achieve low cost and economical use The effect of reducing the amount of formaldehyde released

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

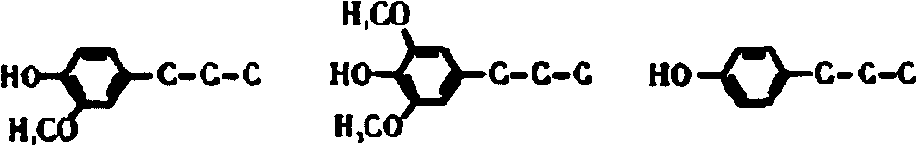

Method used

Image

Examples

preparation example Construction

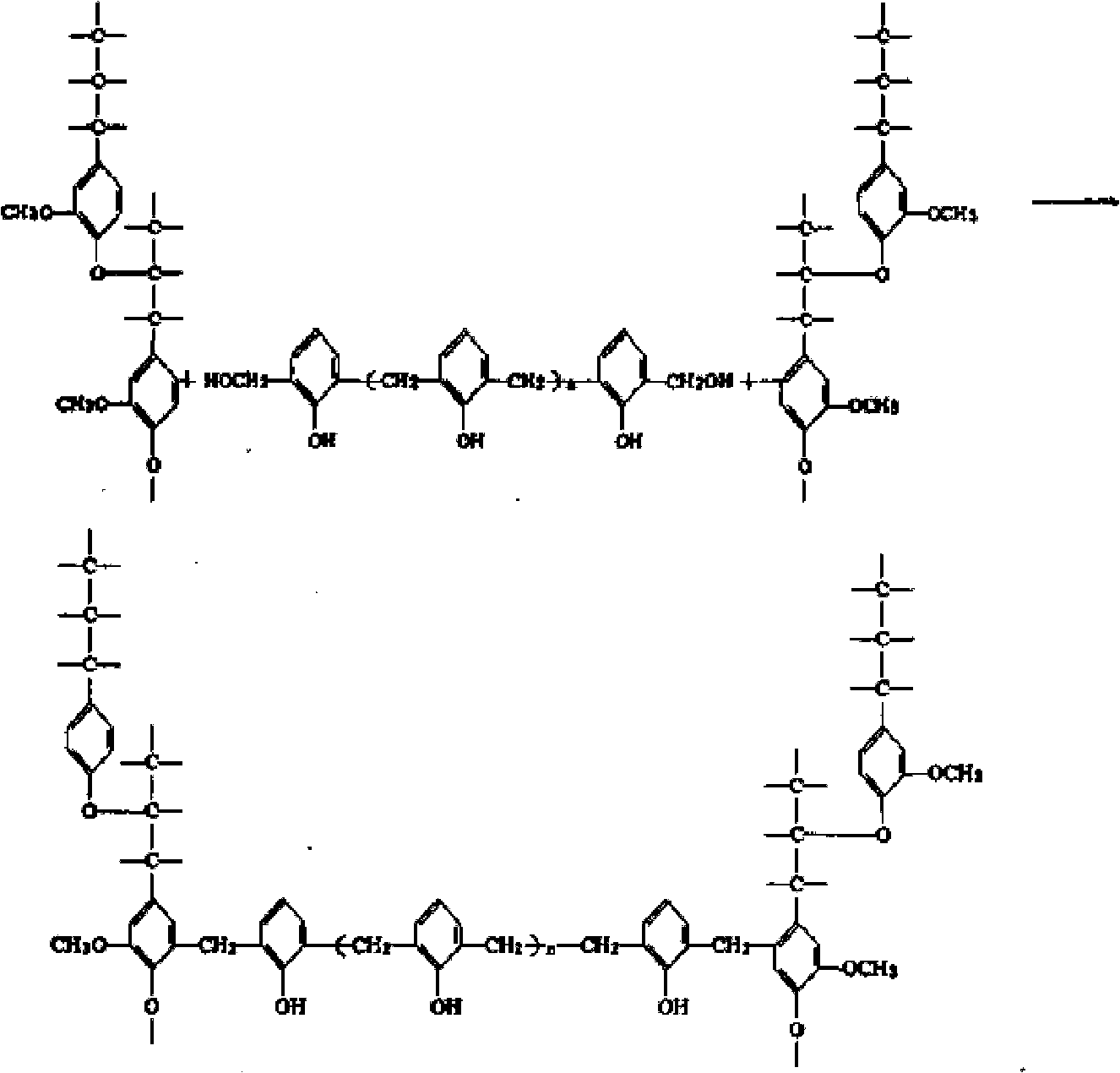

[0022] (2) Preparation of modified phenolic resin binder

[0023] Mix phenol and formaldehyde, under the action of catalyst, keep warm for 1-5h, then add the hydroxymethylated lignin obtained in step (1), continue to react for 1-5h, add organic bentonite, stir for 0.3-1.5h, and obtain modified phenolic resin binder.

[0024] The dosage ratio of formaldehyde and lignin in step (1) is 1:2-1:8, calculated by mass ratio.

[0025] The mass concentration of the NaOH solution in the step (1) is 3%-15%; the volume consumption of the NaOH solution is calculated by dissolving 1g of lignin in 8-20mL of the NaOH solution.

[0026] In the step (1), the constant temperature reaction temperature is 30-90°C.

[0027] The mass ratio of phenol, formaldehyde and hydroxymethylated lignin in step (2) is 2:2:1-8:8:1.

[0028] The catalyst used in the step (2) is sodium hydroxide or oxalic acid; the amount of sodium hydroxide or oxalic acid is 0.5% to 1.5% of the phenol mass.

[0029] In step (2...

Embodiment 1

[0033] (1) Raw materials: lignin, Jiangsu Jingwei Technology Co., Ltd.;

[0034] Other raw materials are commercially available common commodity grade.

[0035] (2) The specific preparation method is as follows:

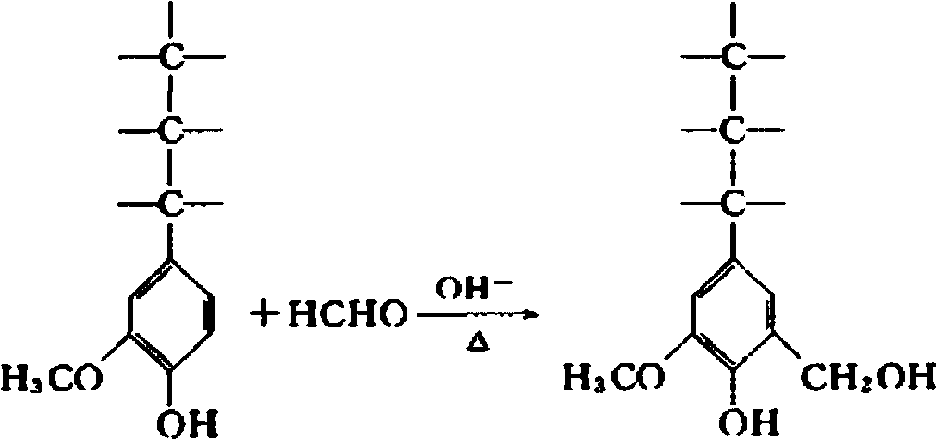

[0036] ①Hydroxymethylation modification of lignin

[0037] Dissolve 12g of lignin in 120mL of NaOH solution with a mass concentration of 7%, heat and stir, slowly drop in 2g of formaldehyde, and react at a constant temperature of 50°C for 2h; then pour the reaction solution into deionized water, stir and add dropwise % hydrochloric acid until the pH value is 3, and the precipitated solid is suction-filtered, washed repeatedly until the washing liquid is neutral, and vacuum-dried at 60°C to obtain hydroxymethylated lignin.

[0038] ② Preparation of modified phenolic resin binder

[0039] Mix 30g of phenol and 30g of formaldehyde, add 0.3g of sodium hydroxide, keep warm at 65°C for 2h, then add 10g of the hydroxymethylated lignin obtained in step (1), continue the r...

Embodiment 2

[0047] (1) Raw materials: lignin, Jiangsu Jingwei Technology Co., Ltd.;

[0048] Other raw materials are commercially available common commodity grade.

[0049] (2) The specific preparation method is as follows:

[0050] ①Hydroxymethylation modification of lignin

[0051] Heat and stir 15g of lignin with 230mL of NaOH solution with a mass concentration of 13%, slowly drop in 5g of formaldehyde, and react at a constant temperature of 80°C for 4h; then pour the reaction solution into deionized water, stir and add dropwise hydrochloric acid with a mass concentration of 13% When the pH value is 4, the precipitated solid is suction-filtered, washed repeatedly until the washing liquid is neutral, and vacuum-dried at 60° C. to obtain hydroxymethylated lignin.

[0052] ② Preparation of modified phenolic resin binder

[0053] Mix 30g of phenol and 30g of formaldehyde, add 0.3g of oxalic acid, keep warm at 85°C for 4h, then add 5g of the hydroxymethylated lignin obtained in step (1),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com