Predecomposition kiln tail system outside of cement kiln, which can treat raw materials with combustibles

A technology of precalcining kiln and processing belt, which is applied in the field of precalcining kiln tail system outside the cement kiln that can process combustible raw materials, and achieves the advantages of improving system operation rate, saving high-quality mine resources, strong operability and practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

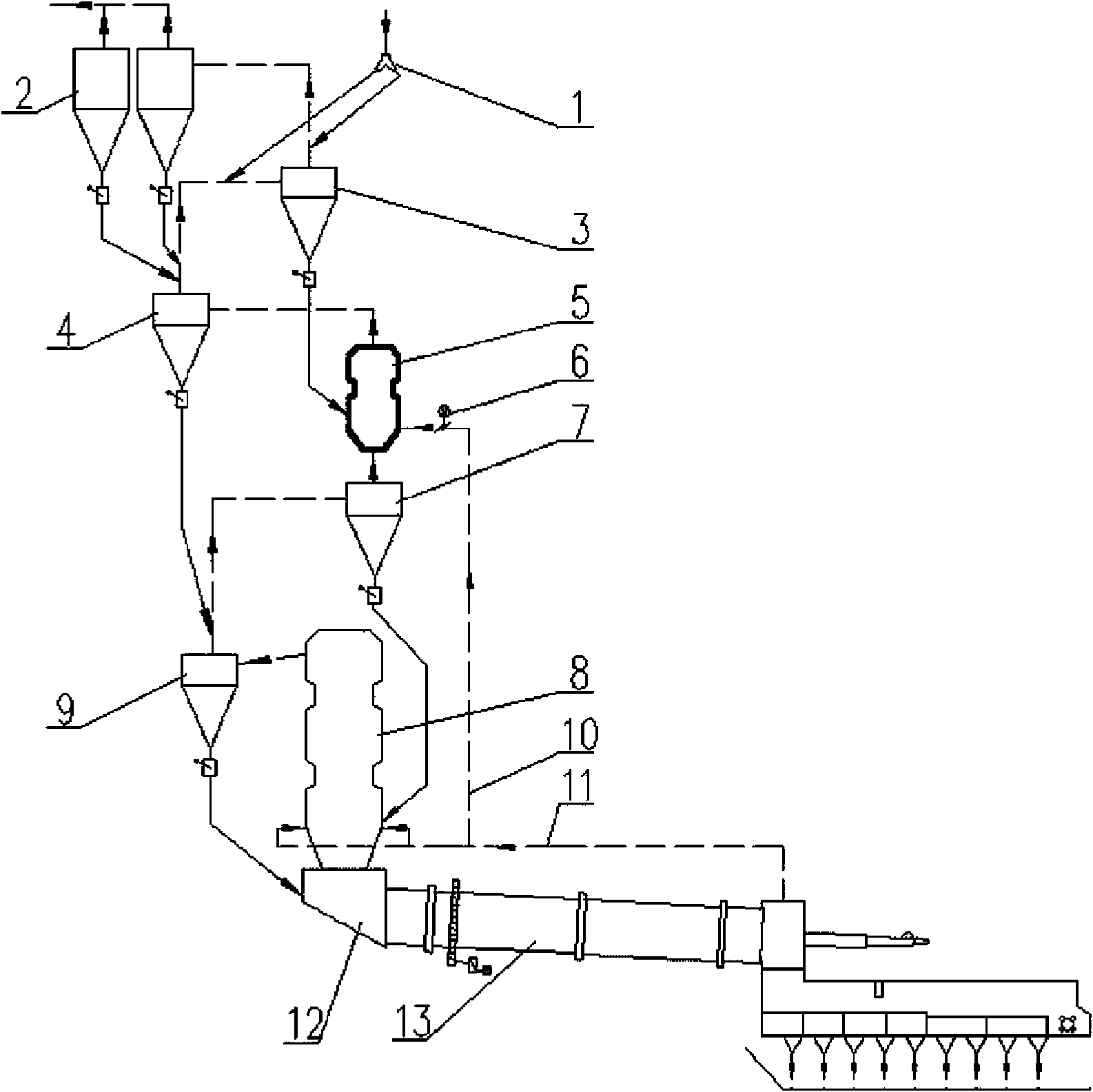

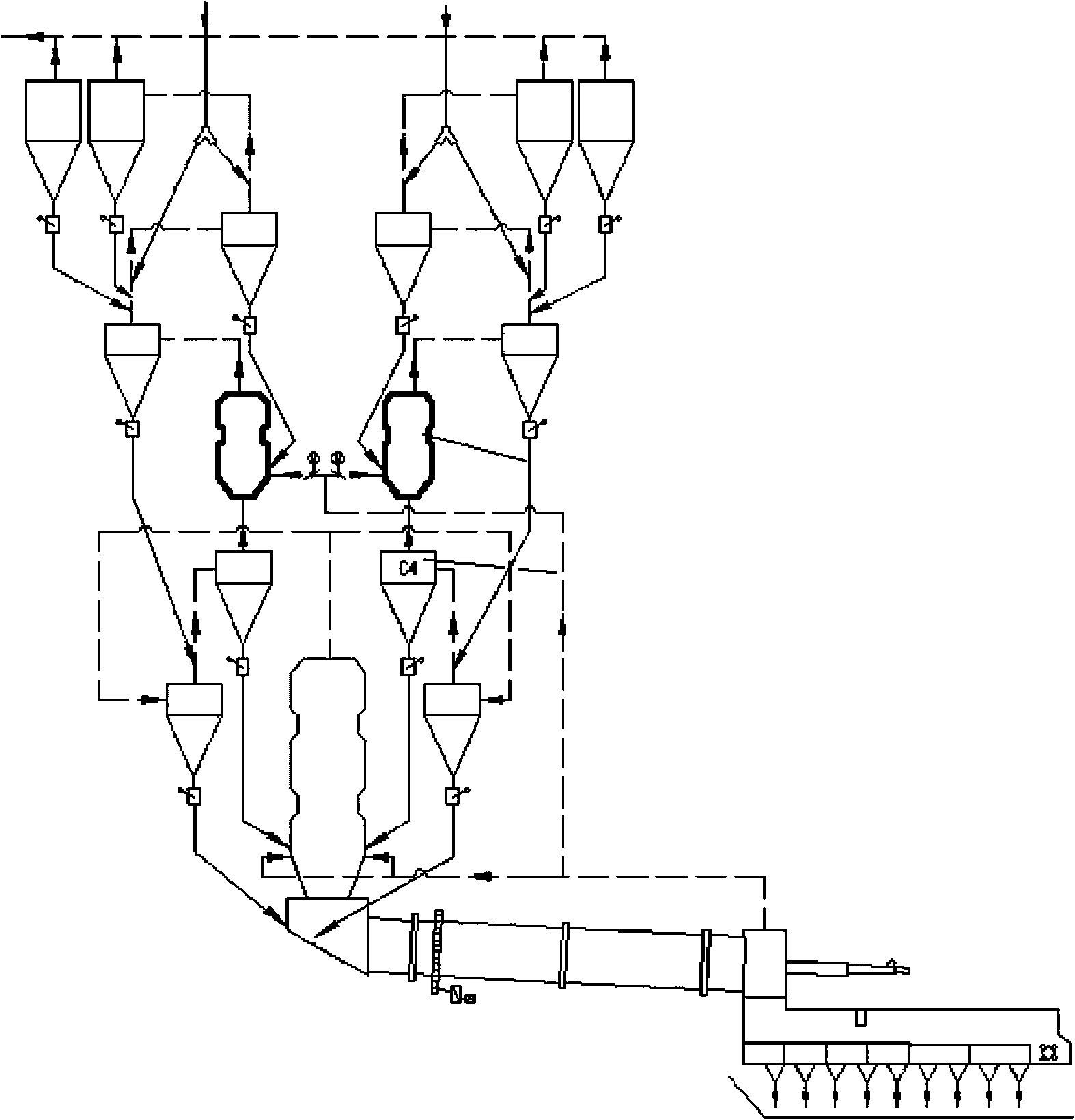

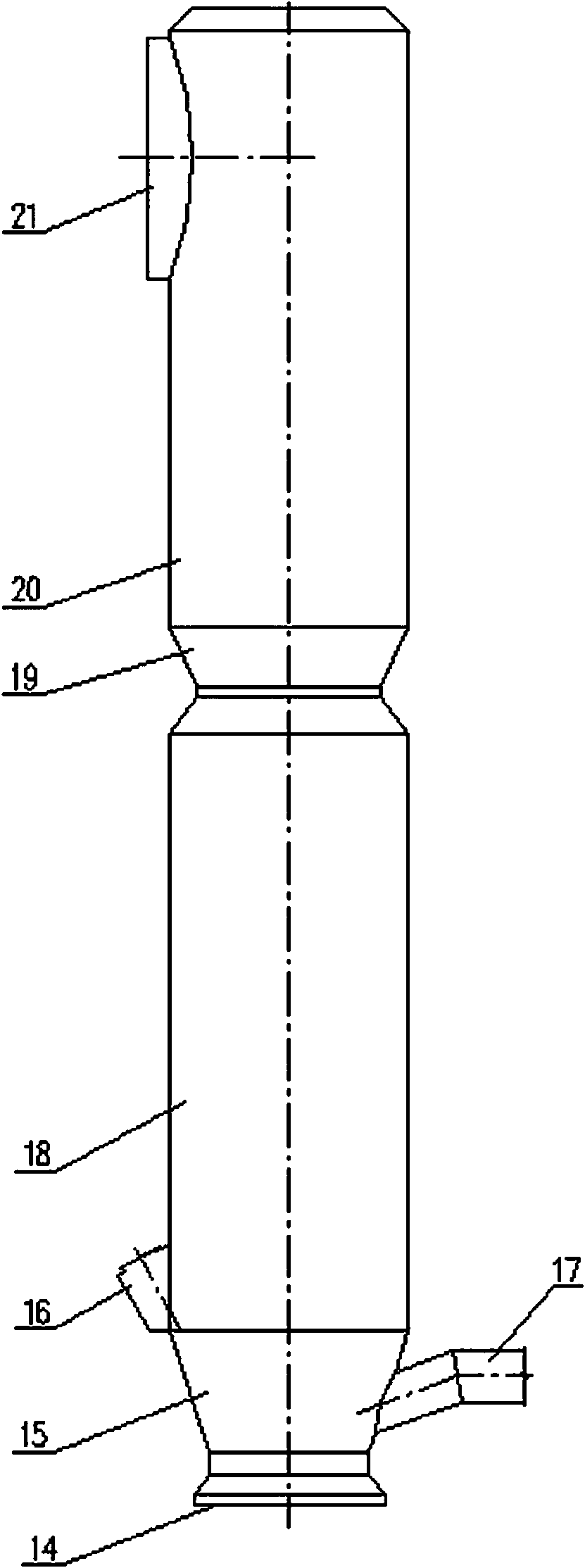

[0023] see figure 1 and image 3 , applying the single series cement kiln external precalcining kiln tail system of the present invention, including feeding device (not shown in the figure), five-stage cyclone preheater, calciner 8, tertiary air pipeline 11, rotary kiln 13, raw meal Pre-calcining furnace 5, the upper part of the raw material pre-calcining furnace 5 is provided with a material airflow outlet 21, the bottom is provided with an airflow inlet 14, and the lower part is provided with a material inlet 16, and the airflow inlet 14 is connected to the air outlet of the fourth-stage cyclone preheater 7 Connect, the air outlet with material is connected to the air inlet pipe of the third-stage cyclone preheater 4, and the material inlet is connected to the discharge port of the second-stage cyclone preheater. The feeding device is provided with a raw meal distributing device 1 . The raw material pre-calcining furnace 5 is connected with the tertiary air duct 11 through...

Embodiment 2

[0036] A cement kiln external pre-decomposition kiln tail system capable of processing raw meal with combustibles. The air inlet of the raw meal pre-calciner is connected to the air outlet of the second-stage cyclone preheater, and the air outlet of the raw meal pre-calciner is connected to the air outlet of the second-stage cyclone preheater. The air inlet pipe of the first-stage cyclone preheater is connected, and the material inlet of the raw meal precalciner is connected with the feeding device. When processing cement raw meal with combustibles, the raw meal is directly fed into the raw meal precalciner, and exchanges heat with the airflow from the second-stage cyclone preheater. After the combustibles in the raw meal are fully burned, it enters the first stage Cyclone preheater, followed by the same structure as conventional kiln tail system to process cement raw meal. Other structures are the same as in Embodiment 1, and the working principle is also the same as in Embod...

Embodiment 3

[0038] A cement kiln external pre-decomposition kiln tail system capable of processing raw meal with combustibles. The air inlet of the raw meal pre-calciner is connected to the air outlet of the third-stage cyclone preheater, and the air outlet of the raw meal pre-calciner is connected to the air outlet of the third-stage cyclone preheater. The air inlet pipe of the second-stage cyclone preheater is connected, and the feeding device is connected with the material inlet of the raw meal precalciner or the air inlet pipe of the first-stage cyclone preheater. When the feeding device is connected to the material inlet of the raw meal pre-calciner, the feeding device will directly send the cement raw meal with combustibles to the raw meal pre-calciner. After the combustibles in the raw meal are fully burned, they enter the second stage. The cyclone preheater is used for gas-solid separation, and other structures are the same as in Embodiment 1, and the working principle is also the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com