Optical fiber vibration sensing head and manufacturing method thereof

A fiber optic vibration and sensing head technology, applied in the physical field, can solve problems such as complex assembly, difficult wavelength demodulation, and narrow frequency response range of optical detection vibration sensors, and achieve good consistency, expanded operating frequency range, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

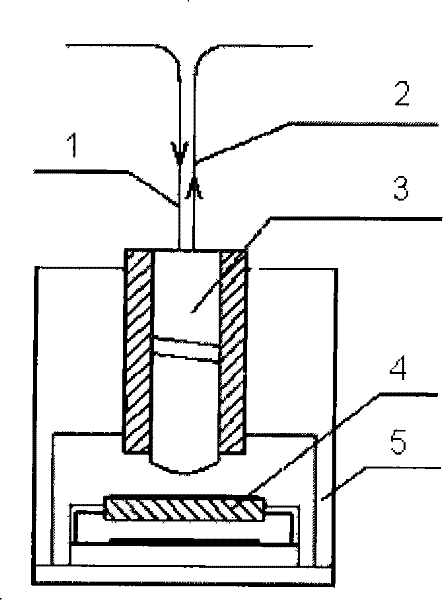

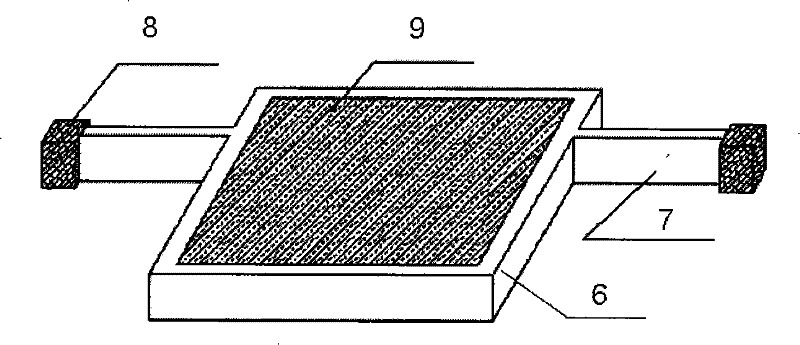

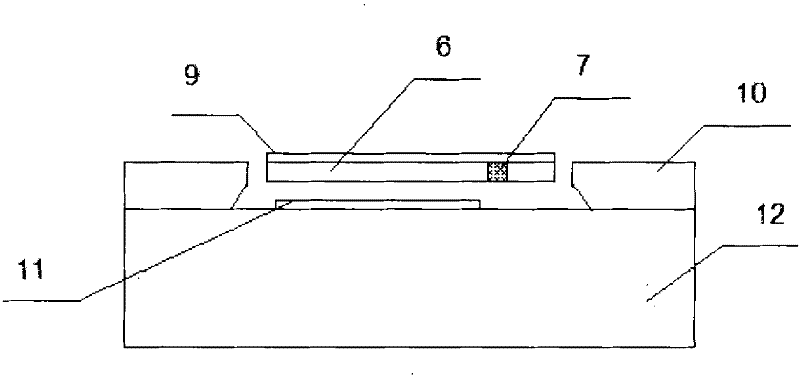

[0030] Such as figure 1 , figure 2 and image 3 As shown, the optical fiber vibration sensing head of the present invention is composed of a vibration sensitive chip 4, a double fiber collimator 3 and a package housing 5, and an input optical fiber 1 and an input fiber 1 are arranged in the described double fiber collimator 3 An output optical fiber 2, wherein the dual-fiber collimator 3 is fixedly arranged on the upper part of the package housing 5, and a cavity is provided in the package housing 5 below the dual-fiber collimator 3, and the vibration-sensitive chip 4 is arranged in the cavity, and the vibration-sensitive chip 4 is composed of a low-light reflector 6, a silicon support frame 10 and a substrate glass sheet 12, and the silicon support frame 10 is bonded to the substrate glass sheet 12 Together, the low-light reflector 6 is arranged in the silicon support frame 10, a damping air cavity is arranged between the low-light reflector 6 and the substrate glass sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com