Method for improving focusing and leveling measurement accuracy

A technology for focusing, leveling, and measuring accuracy, which is applied to the photoplate-making process, optics, and instruments on the patterned surface to avoid the effect of measuring repeat accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

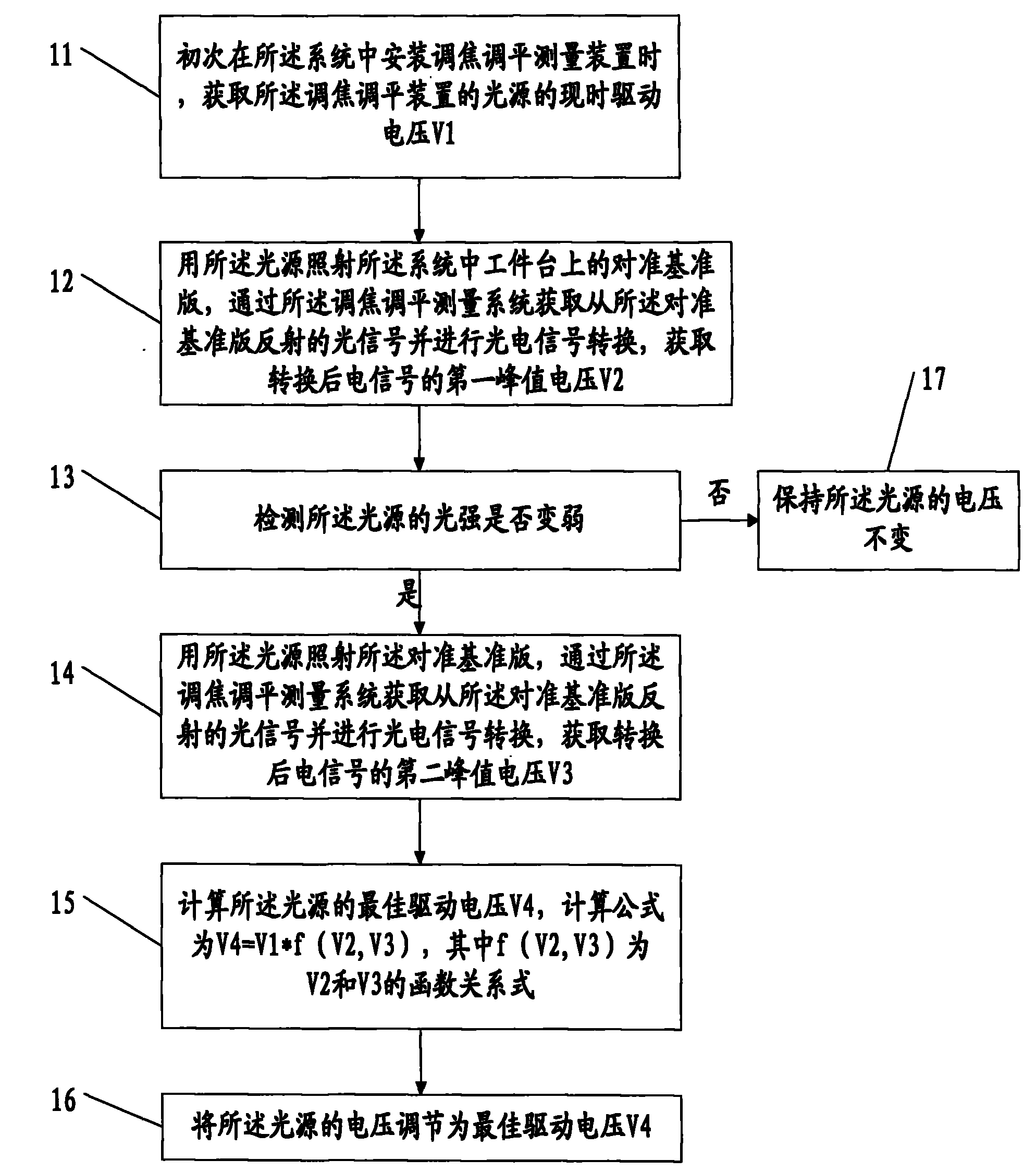

[0012] Below, the present invention will be further described in conjunction with the accompanying drawings.

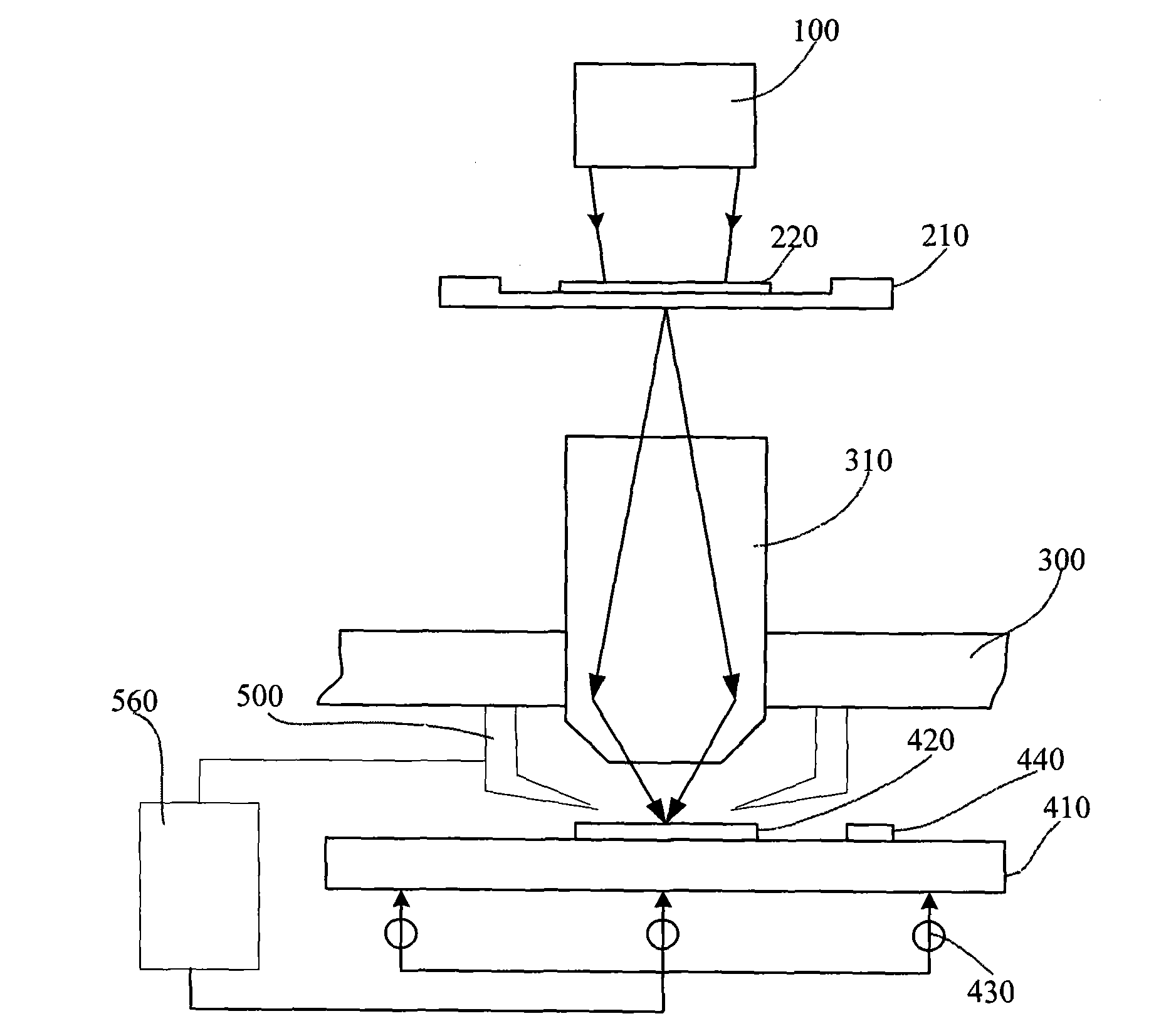

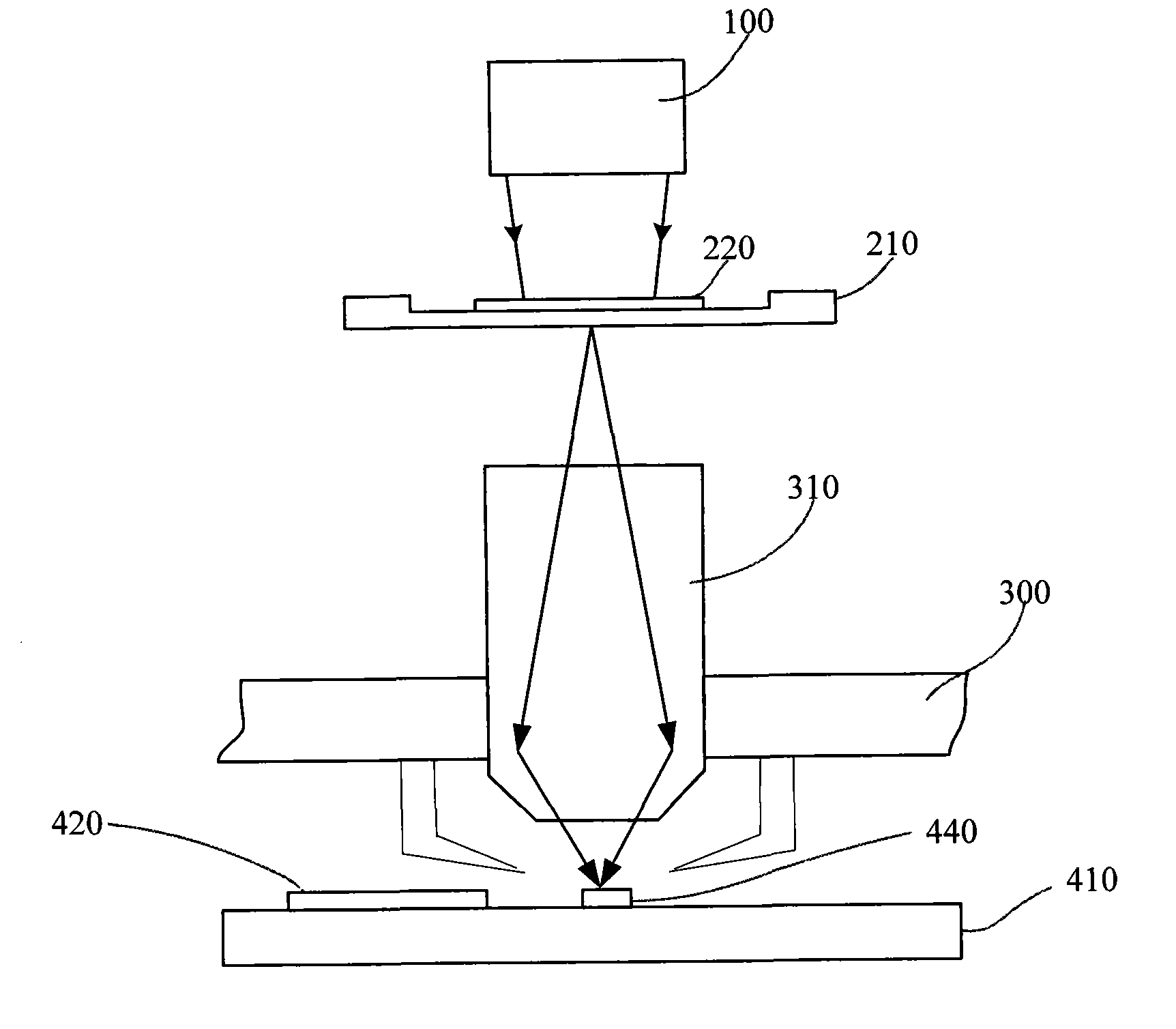

[0013] First, please refer to figure 1 , figure 1 It is the first schematic diagram of the optical exposure system. It can be seen from the figure that under the illumination of the illumination system 100 , the light source of the illumination system 100 projects and exposes the image on the mask 220 onto the silicon wafer 420 through the projection objective lens 310 . Mask 220 is supported by mask stage 210 , and silicon wafer 420 is supported by work stage 410 . exist figure 1 Among them, there is a silicon wafer focusing and leveling measurement device 500 between the projection objective lens 310 and the silicon wafer 420, which is rigidly connected with the projection objective lens support 300, and is used for measuring the position information on the surface of the silicon wafer 420, and the measurement results are sent to The silicon wafer surface positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com