CNC Double Knife Turning Vertical Lathe

A turning and vertical turning technology, applied in turning equipment, turning equipment, wheels, etc., can solve the problems of multiple operators, occupy a lot of space, affect the turning accuracy of wheels, etc. The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific embodiments.

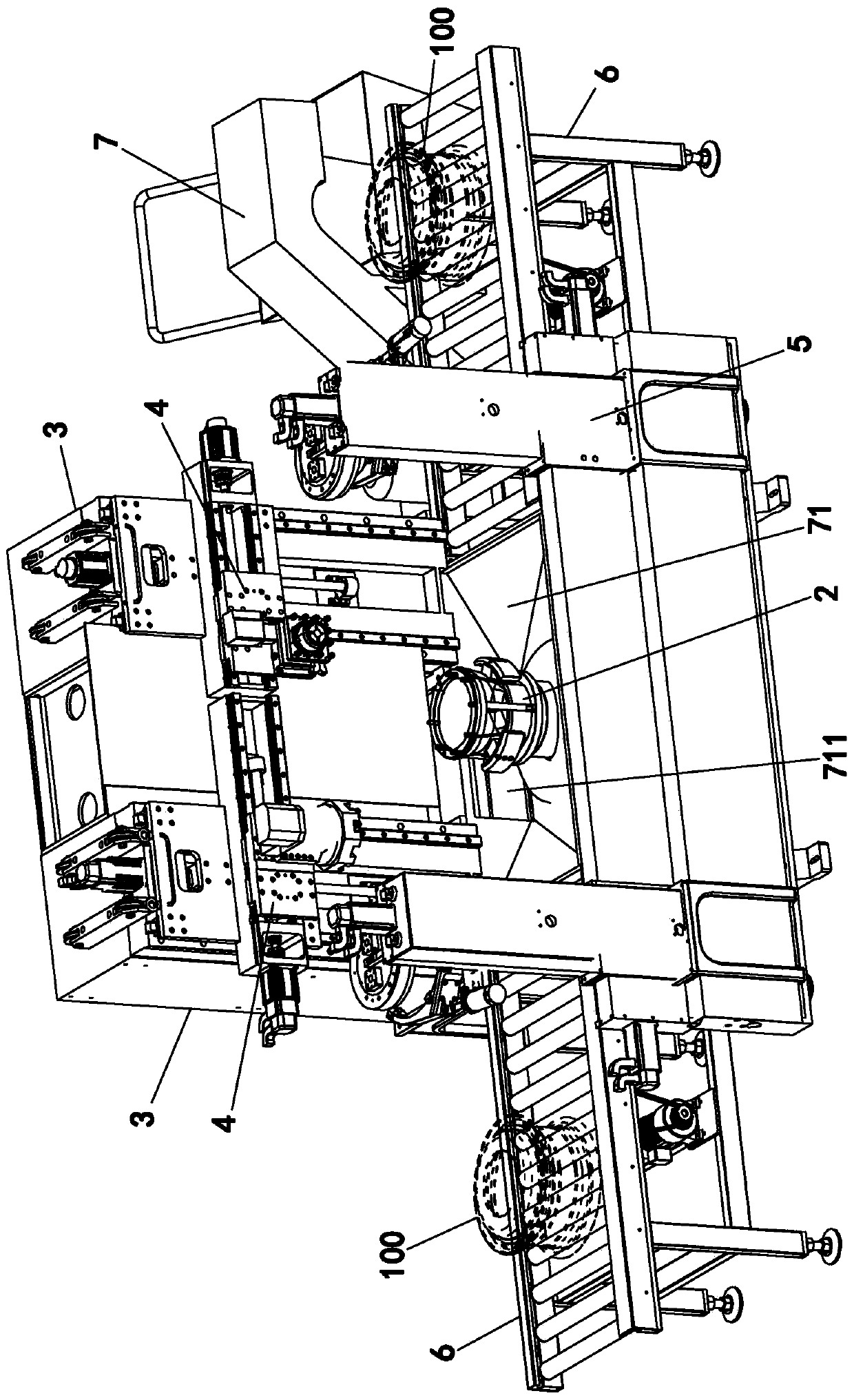

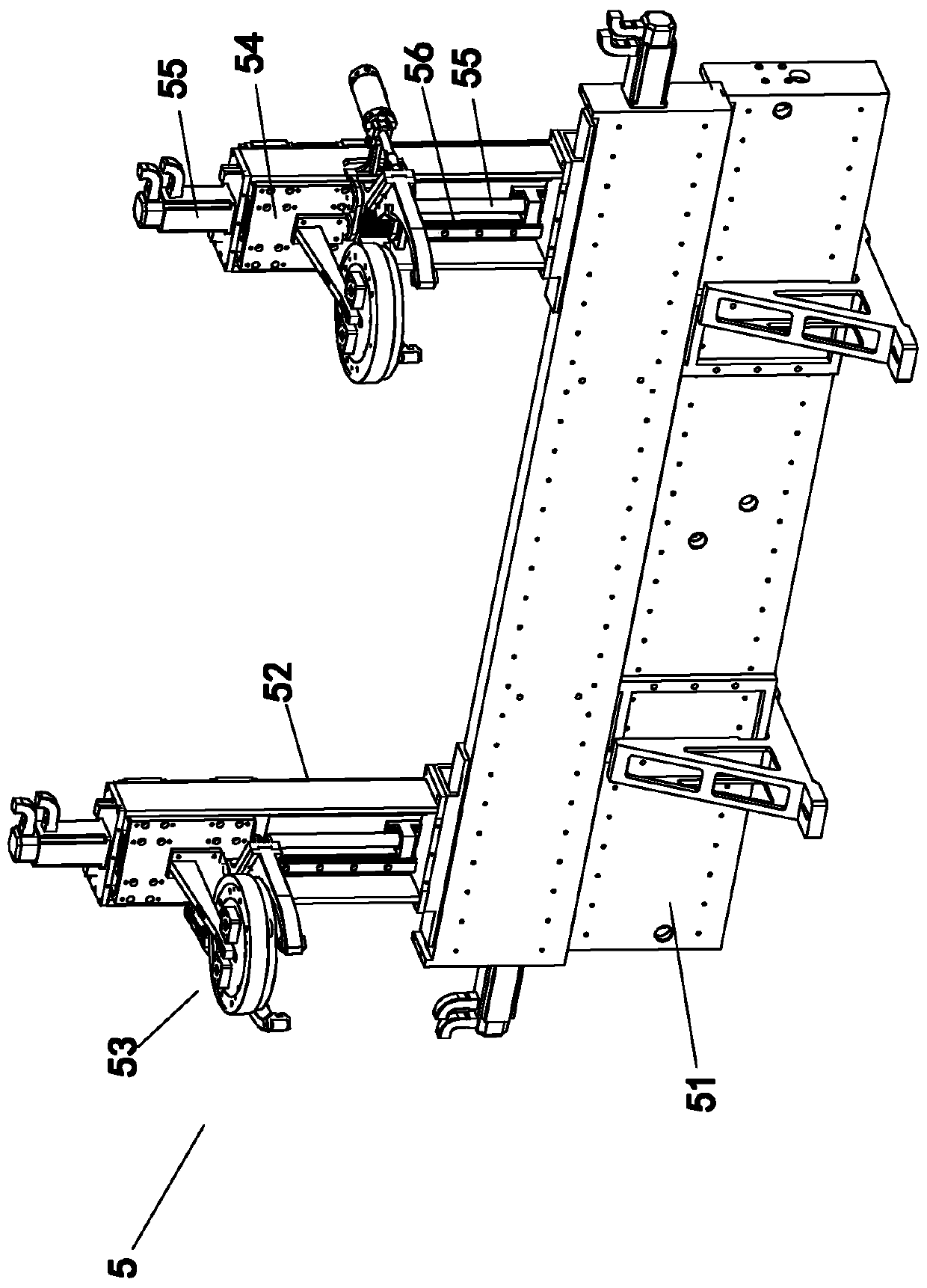

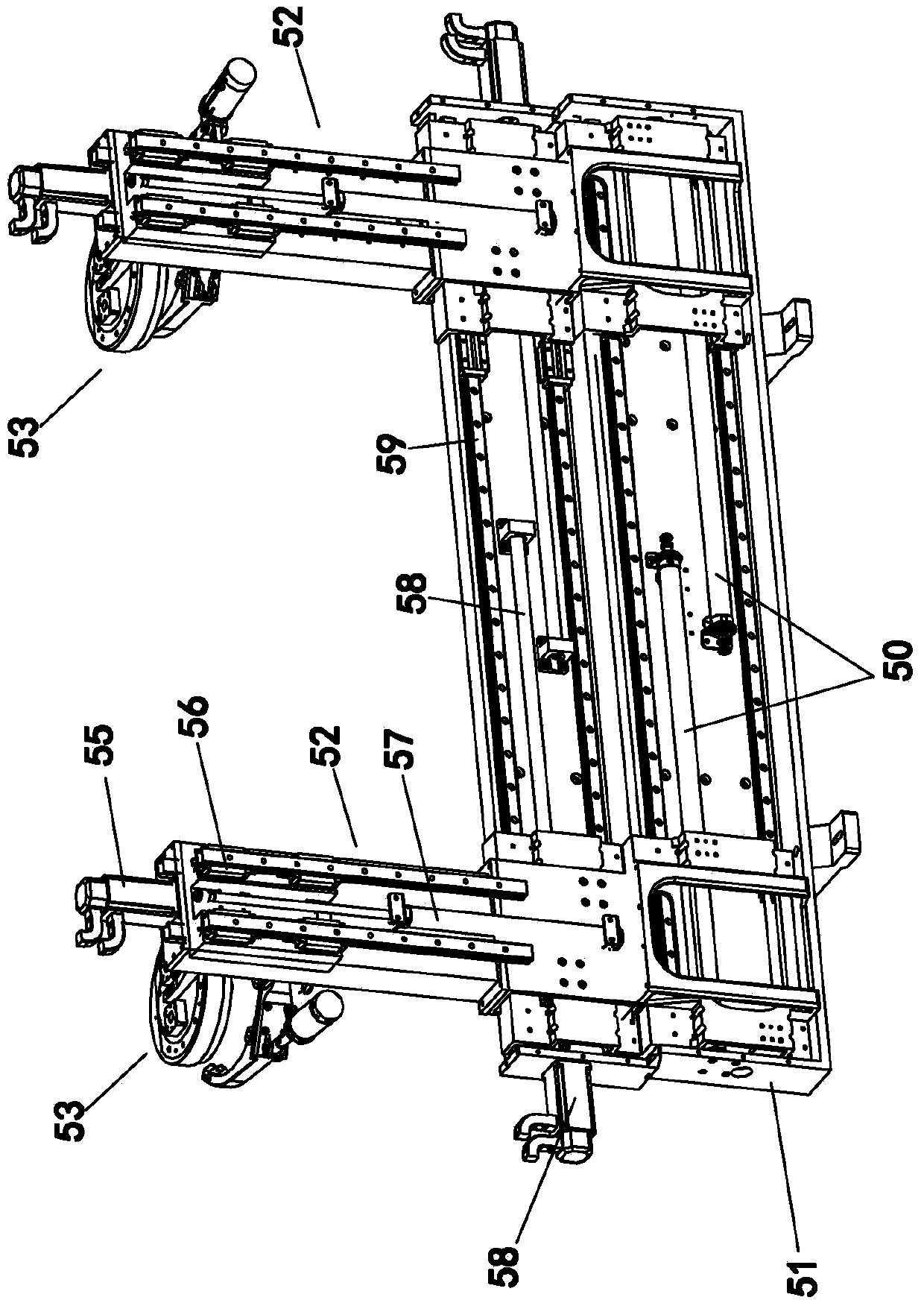

[0066] A CNC double-tool turning vertical lathe, such as figure 1 , Figure 8 with Picture 9 Shown, including base 1, bottom mold device 2, tool holder 3, turning tool set 4, manipulator assembly 5, conveyor 6, chain plate chip conveyor 7, protective cover 8 and numerical control system (not shown in the figure) . The operation of the whole machine is controlled by a numerical control system. The turning vertical lathe is suitable for turning processing of many industrial workpieces. The following workpieces are processed by taking the wheel as an example to describe the mechanical structure in detail. The numerical control system is the control, programming program and circuit connection part. No more detailed description.

[0067] The base 1, such as Image 6 with Figure 7 As shown, for the installation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com